Mounting structure for sound insulation board

A technology for installing structures and sound insulation boards, which is applied in sound insulation, building components, building structures, etc., can solve the problems of inconspicuous effects and occupying a large space area, and achieve good sound insulation and shock absorption effects, improve the quality of life, and fire prevention functions and the effect of the thermal insulation function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

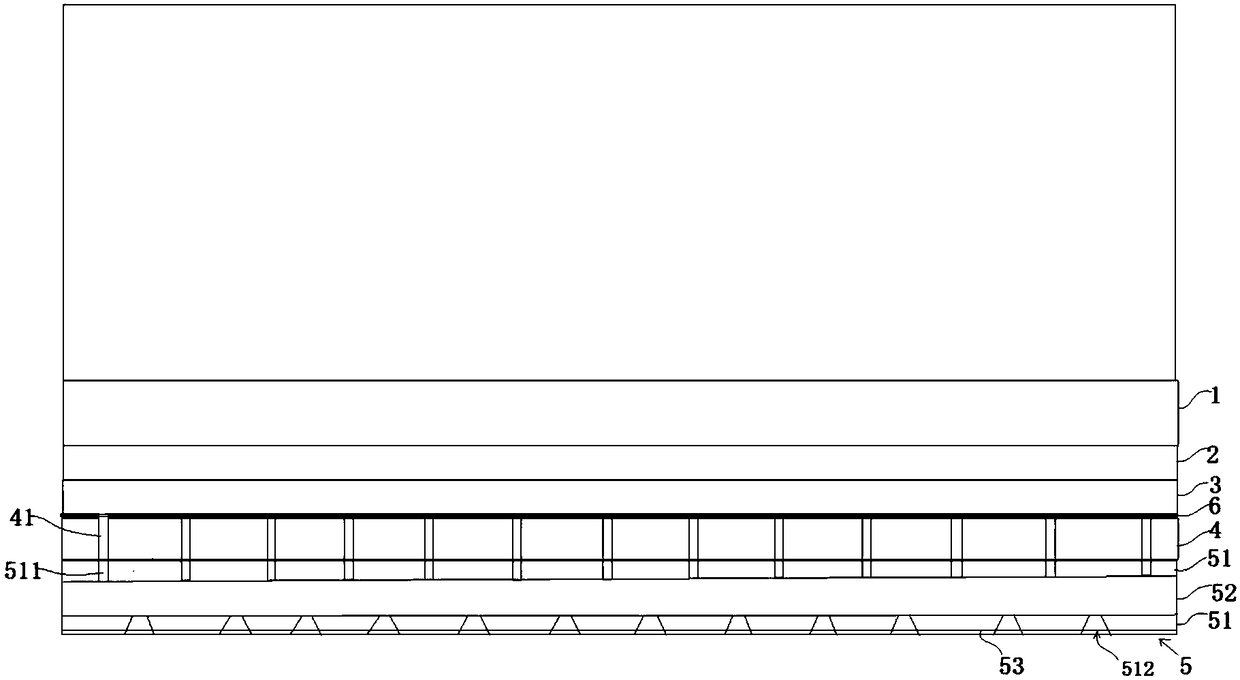

[0027] Example: such as figure 1 As shown, a sound insulation board installation structure includes a putty layer 1, a sound insulation cotton layer 2, a silica gel layer 3, a gypsum layer 4, a fireproof sound insulation board 5, and an anti-cracking net 6.

[0028] Wherein, the putty layer 1 is coated on the surface of the cement wall. When coating, it needs to be coated evenly to prevent drumming. After the putty layer 1 is completely dry, proceed to the next step. In consideration of the dual factors of room use area and sound insulation effect, the thicknesses of putty layer 1, sound insulation cotton layer 2, silica gel layer 3, gypsum layer 4, and fireproof sound insulation board 5 need special attention during design. In this embodiment , The thickness of the putty layer 1 is 5mm-10mm, preferably 8mm.

[0029] The sound insulation cotton layer 2 is arranged on the surface of the putty layer 1 . The thickness of the sound-insulating cotton layer 2 is 5mm-10mm, prefer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com