Safe power cable device

A power cable and safety technology, applied in the field of electric power, can solve the problems of difficult to control the position of the center of gravity of the cable, insufficient clamping stability of the cable, complicated design structure, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

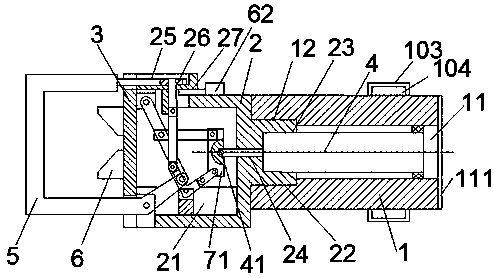

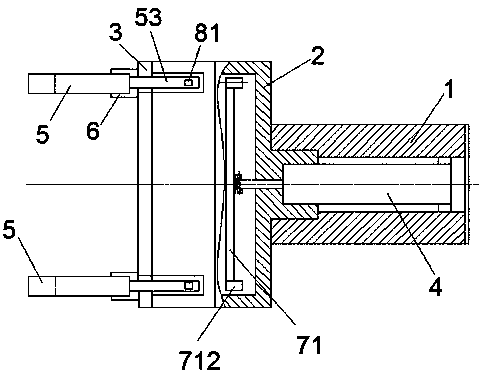

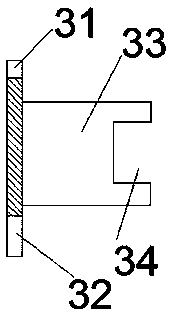

[0031] like Figure 1-Figure 11 As shown, a safe power cable device of the present invention includes a chuck 1 connected to the conveyor, and a second air hole 21 fixed on the left end of the chuck 1 and provided with a mouth to the left, the upper surface is provided with The front side groove 25 and the base 2 of the first opening 27 are arranged on the right side of the second empty opening 21 below the front side groove 25, and the base 2 in the middle part of the front side groove 25 is provided with an up-down direction The second opening 26 of the base, and a plate 3 fixedly installed on the left end of the base 2 and extending rightward into the second opening 21, and two sets of connecting frames, and a hydraulic cylinder 4, and two clips Tight claw 5, and the electromagnetic device installed on the upper surface of the base 2 on the right side of the first port 27, and two fixed blocks 6 fixed on the left side of the plate 3, the right end surface of the chuck 1 A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com