Filter net multi-size positioning roller

A multi-size, roller technology, which is applied in metal processing and other directions, can solve the problems of confusion of sizes and specifications, the filter cannot be used normally, etc., and achieve the effect of increasing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

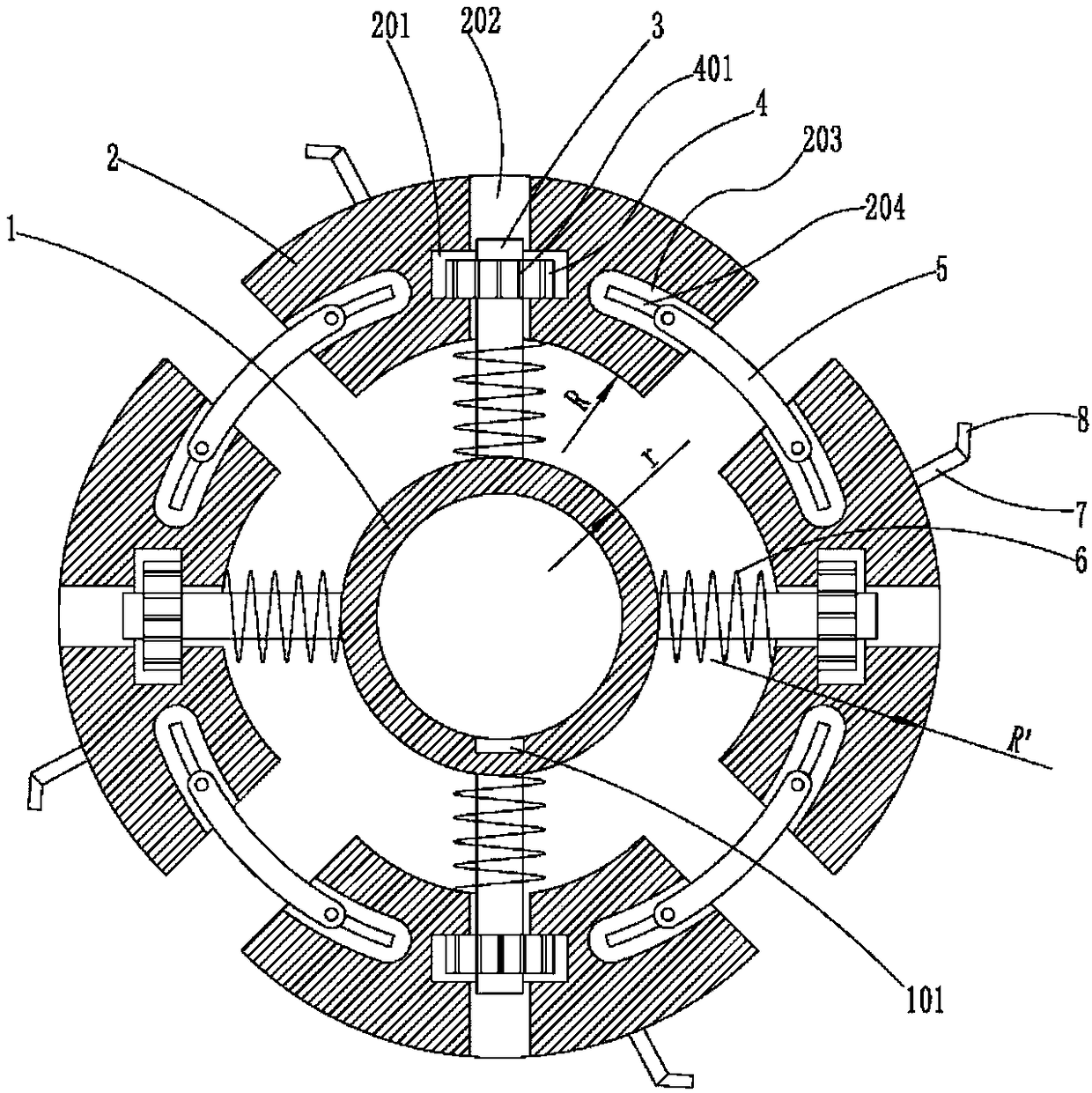

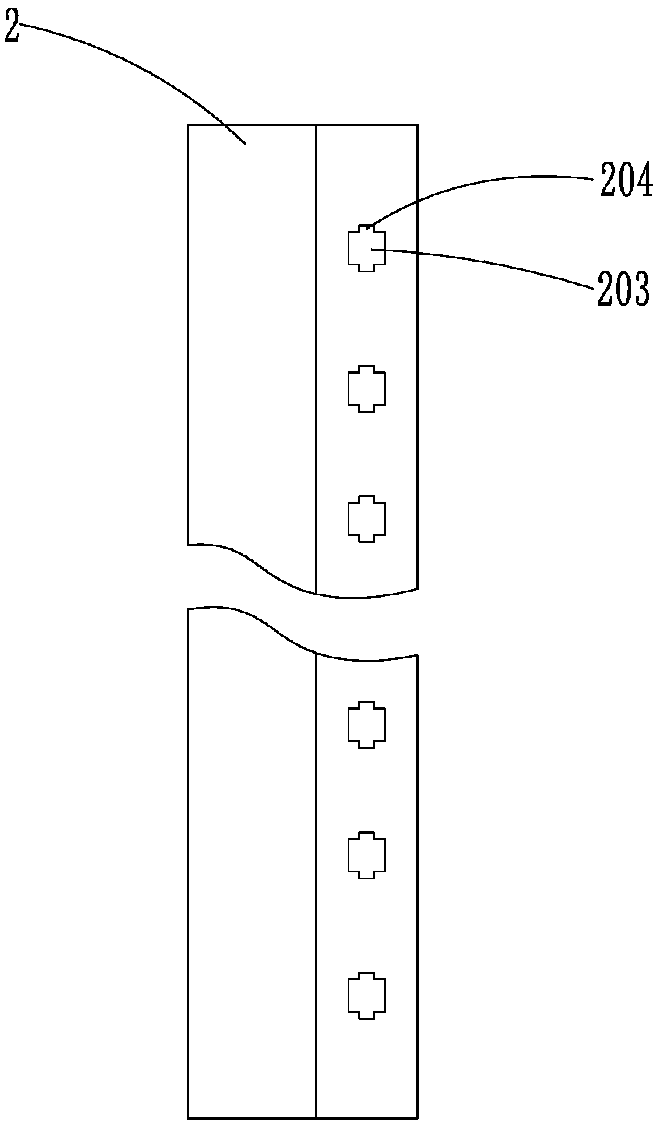

[0016] Such as Figure 1 ~ Figure 2 As shown, a filter screen multi-size positioning roller according to the present invention includes a shaft sleeve 1, and key grooves 101 are provided on both ends of the shaft sleeve 1. During installation, the key groove 101 is used to cooperate with the flat key on the installation shaft. Ensure that the shaft sleeve 1 can rotate synchronously with the installation shaft; there are four adjustment blocks 2 concentric with the shaft sleeve 1 around the shaft sleeve 1, the cross-sectional shape of the adjustment block 2 is a fan-shaped structure, and the radius of the inner arc surface of the adjustment block 2 is R, the radius of the outer arc surface of the adjustment block 2 is R', the radius of the outer circumferential surface of the shaft sleeve 1 is r, wherein R'=2R=2r; the radius of the inner arc surface of the adjustment bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com