Production device for lead sinker

A technology of production equipment and sinkers, which is applied to other manufacturing equipment/tools, manufacturing tools, metal extrusion dies, etc., can solve the problems of complex mold structure, low production efficiency, inconvenient demoulding, etc., and achieve simple mold structure, The effect of easy operation and low difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below through specific embodiments.

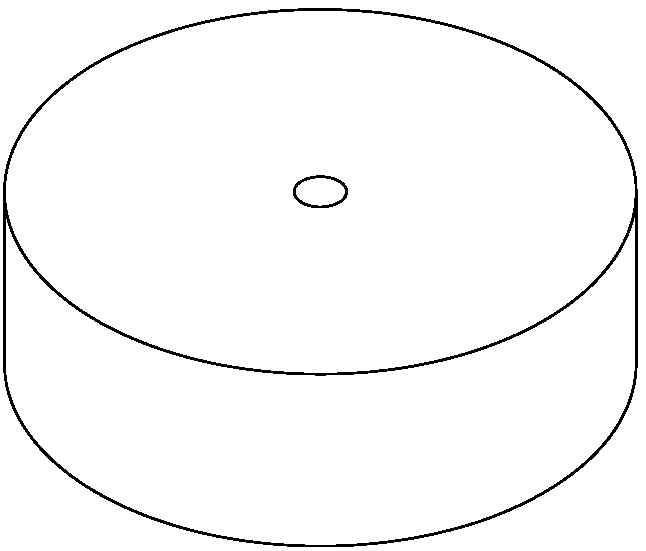

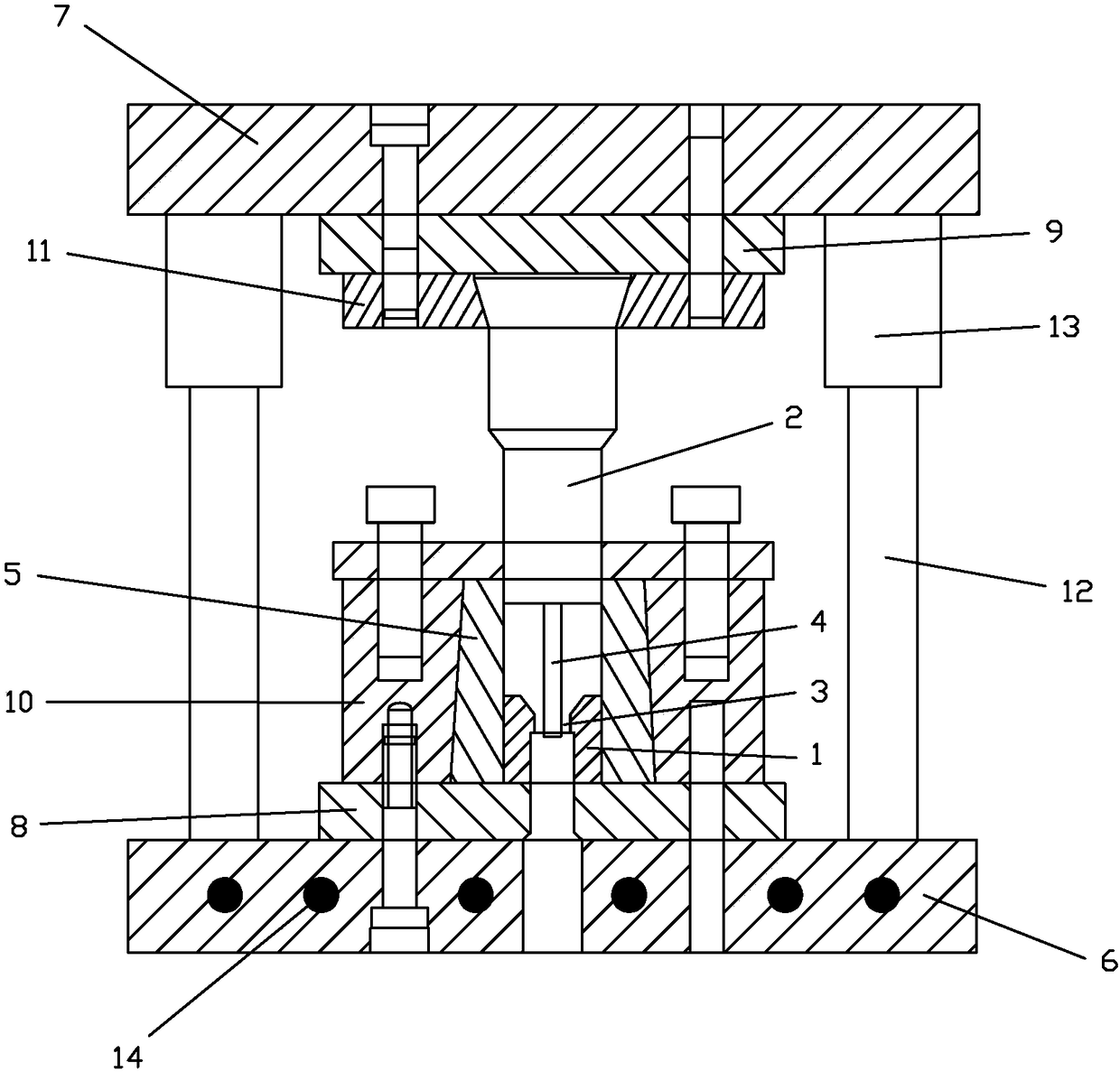

[0033] refer to Figure 1 to Figure 10 , a kind of lead sinker production equipment of the present invention, comprises the lead billet casting device that is used for melting and casting lead raw material into lead billet, is used to extrude the lead billet into the lead pipe extrusion mold of hollow lead pipe and is used for Lead pellet rolling cutting device for cutting lead pipe into lead pellets.

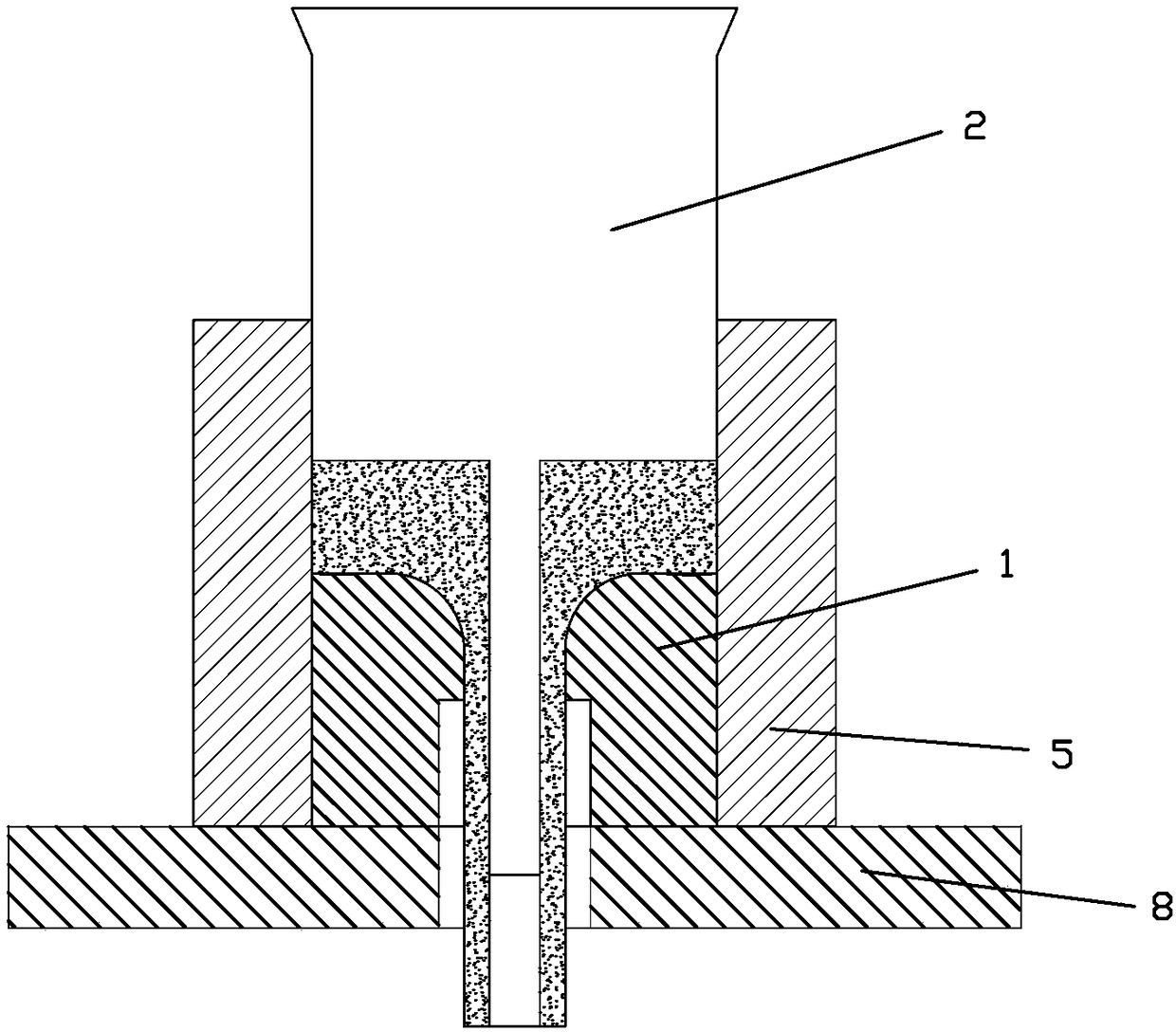

[0034] The lead pipe extrusion molding die includes a die 1 and a punch 2, the die 1 is formed with a cylindrical channel 3, the punch 2 can be lifted and lowered to be arranged above the die 1 through a guide device, and the punch 2 is formed with a corresponding concave The center of the cylindrical channel 3 of the die 1 is arranged and extends into the cylindrical rod 4 in the cylindrical channel 3 of the die 1 . A prestressing ring 5 is sheathed outside the die 1 , and the prestr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com