Novel crusher

A crusher, a new type of technology, applied in the direction of grain processing, etc., can solve the problems of easy damage to the drive shaft, easy to collapse of broken slag, etc., to achieve the effect of convenient use, reasonable structure, and reduced impact force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

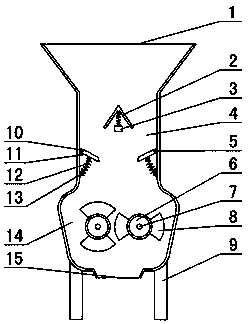

[0012] Example 1: According to figure 1 with figure 2 , A new type of crusher, which includes a crushing bin 14; the upper side of the crushing bin is provided with a blanking channel 4 and a feed inlet 1, and the bottom is provided with a leg 9 and a discharge port 15; the inside of the crushing bin 14 There is a set of transmission shafts 7 distributed in parallel; the transmission shaft is provided with a rotating roller 6; the outside of the rotating roller is provided with staggered crushing heads 8; the inside of the blanking channel 4 is respectively provided with Multiple sets of ear plates 10 distributed in parallel are provided with a buffer plate 11 rotatably connected by a rotating shaft 5; below the buffer plate are provided multiple sets of springs 12 connected with the inner wall of the blanking channel 4; the blanking channel A crossbeam 3 located above the buffer plate is provided inside; a distributor 2 connected by a spring is provided on the crossbeam.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com