High-shear emulsifying and wall-scraping stirring device

A technology of high-shear emulsification and wall-scraping agitation, which is applied to mixers with rotating agitation devices, transportation and packaging, and mixer accessories. The process of emulsification and stirring is uniform and the effect is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

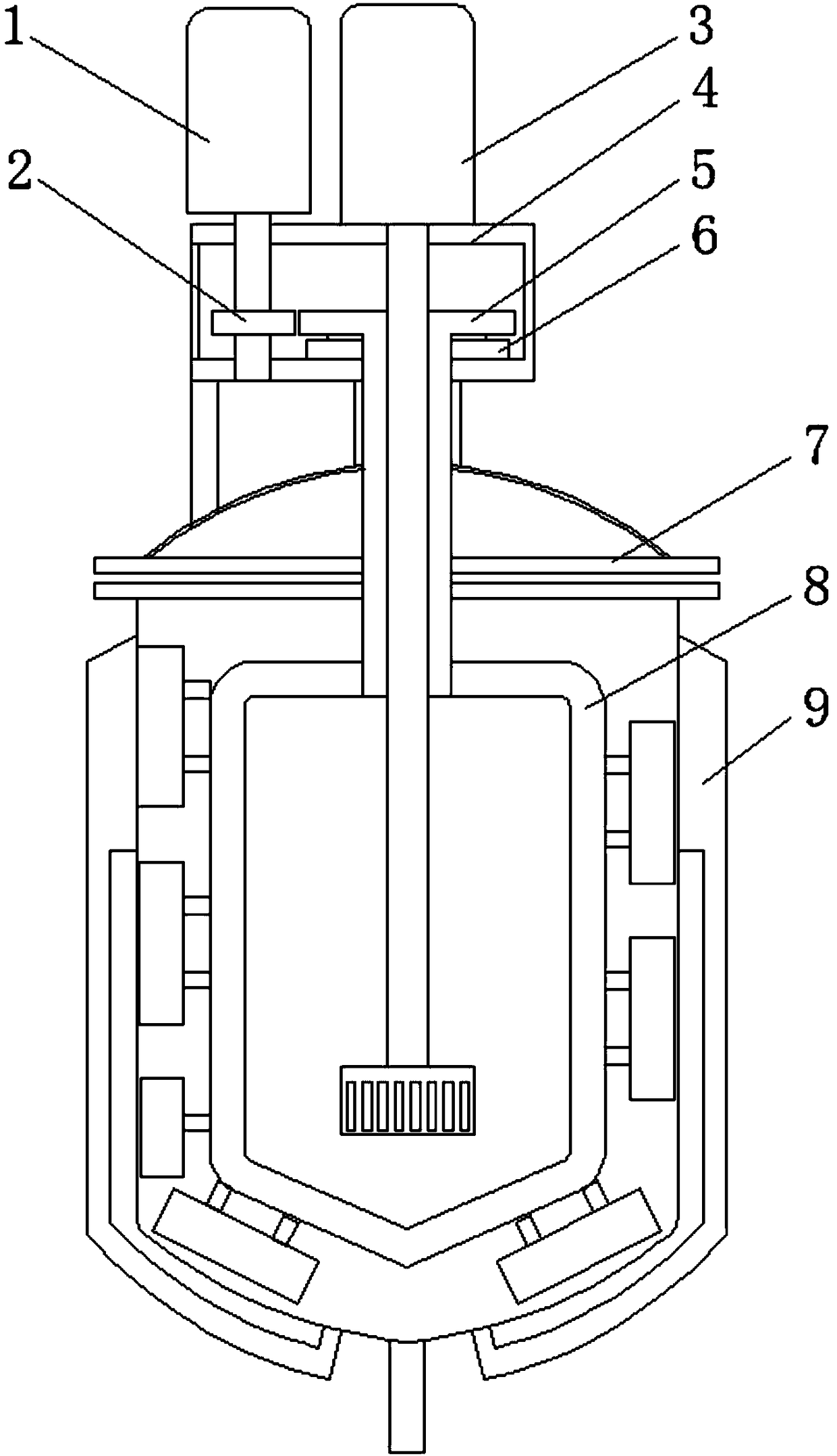

[0024] A kind of high-shear emulsification and wall scraping stirring device among the present invention, such as figure 1 As shown, the device includes a reaction tank, a high-shear emulsifier 3, a scraper stirring assembly 8 and an agitation reduction motor 1. The rotating shaft of the emulsifier driven, the scraper stirring assembly 8 includes a stirring rotating shaft, a rotating frame fixedly connected with the rotating shaft and a scraper fixedly connected with the rotating frame, and the rotating shaft of the emulsifier passes through the stirring rotating shaft The axis of the shaft combines the advantages of the high-shear emulsifier and the wall-scraping stirring assembly, effectively solving the four corners existing in the stirring process, and the stirring is more uniform and thorough. The high-shear emulsifier ensures a more uniform emulsification process, and the entire device is set compact.

[0025] The specific settings are:

[0026] Such as figure 1 As sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com