Application method of beating machine

A technology of machinery and paddle shaft, applied in the field of organic fertilizer processing machinery, can solve the problems of inability to completely pulverize and emulsify, affect the utilization rate of fertilizer, and low production efficiency, and achieve the effects of simple product structure, high production efficiency and fast emulsification speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

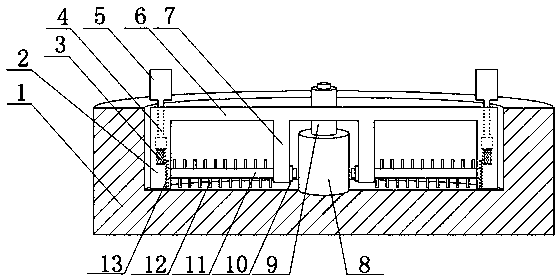

[0024] The present invention will be described below in conjunction with the accompanying drawings. figure 1 It is a schematic cross-sectional structure diagram of the present invention.

[0025] A kind of using method of beating machine of the present invention, wherein, comprises the steps:

[0026] A. First, cut the decomposed and press-filtered block or cake-shaped bio-organic fertilizer into block materials of about 10×10cm, then put the cut materials into the beating tank, and pour a certain proportion of water or emulsion;

[0027] B. Turn on the rotating motor, so that the output shaft of the rotating motor drives the rotating shaft to rotate, and then drives the rotating frame, the outer column of the beating shaft, and the inner column of the beating shaft to rotate with the rotating shaft as the center;

[0028] C. Further turn on the power supply of the emulsification motor, so that the output shaft of the emulsification motor drives the gear shaft to rotate, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com