Method for manufacturing wedge block having same length of curves of each cross section

A technology with equal length and section curves, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of affecting blade life, reducing strength, and wedge top not in place, so as to improve blade life and reduce strength , to avoid loose effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing, the present invention is further described:

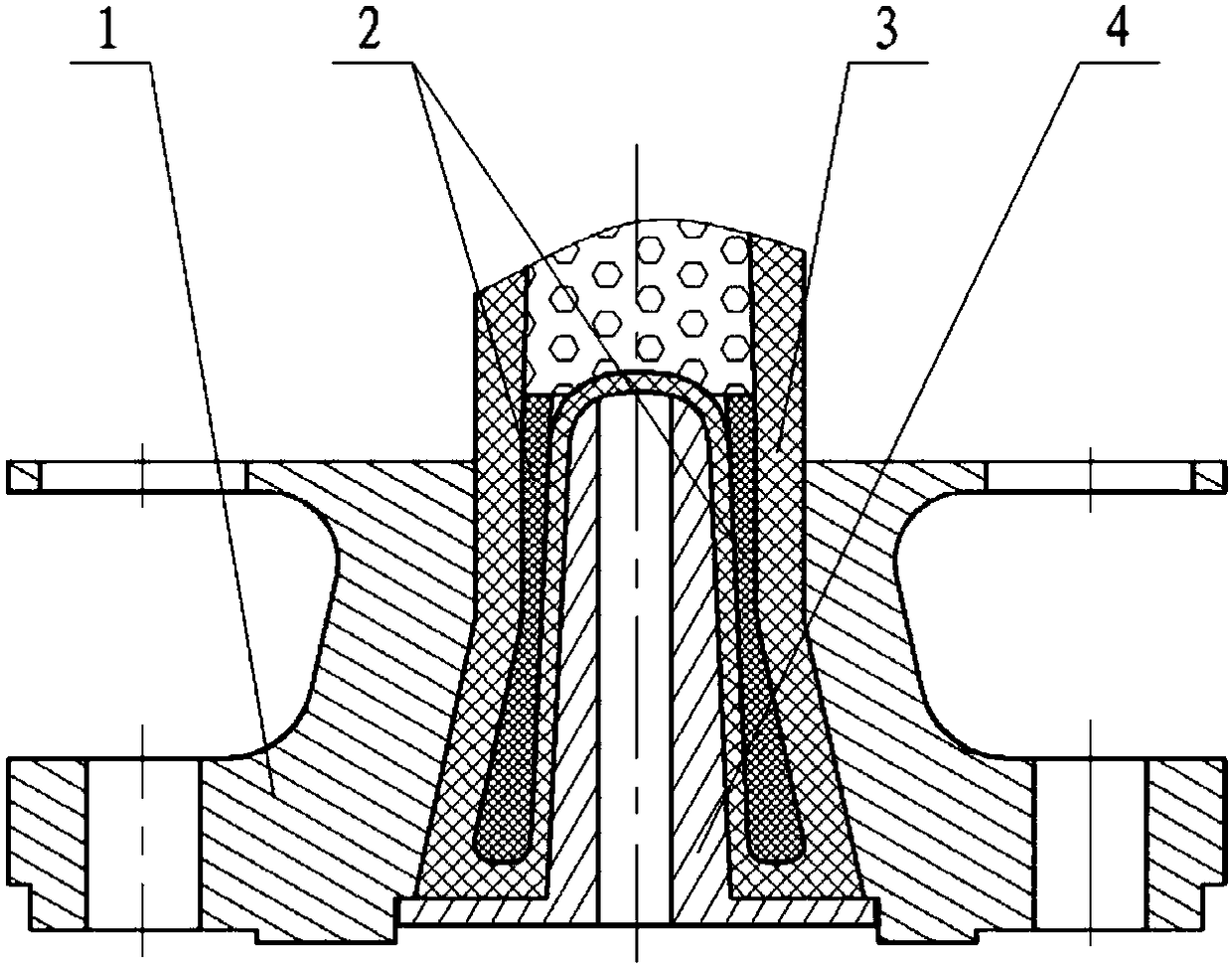

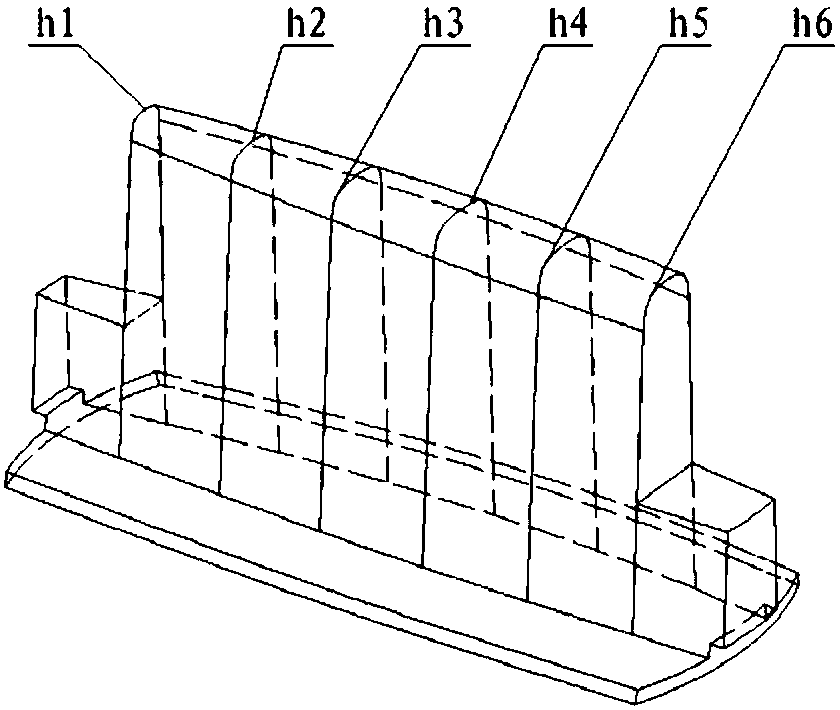

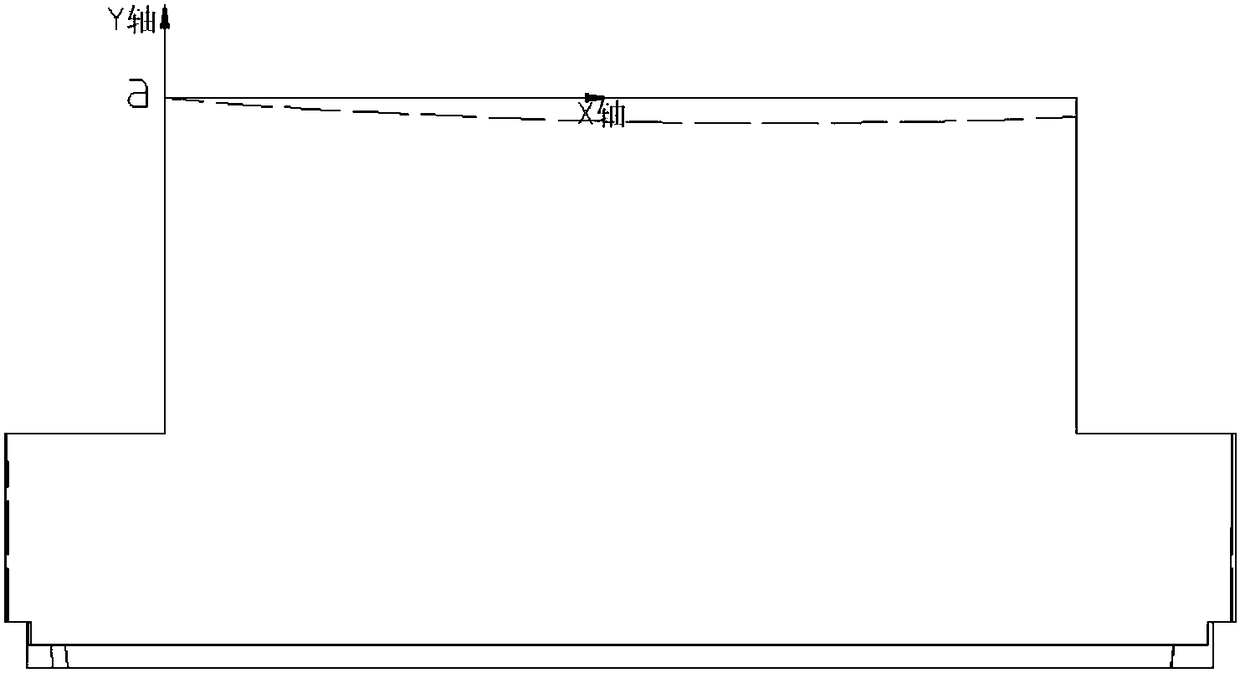

[0017] A wedge block structure with equal length of each section curve, the wedge block is a blade root structure for integral molding, there is a square hole inside the metal flange 1, and the carbon beam extending from the blade body is wound from one side and placed on the flange. The two prefabs 2 in it extend from the other side to the blades; the carbon beams wrapped around the prefabs 2 are tightened with wedges to achieve one-piece molding. In order to better hold the carbon fiber cloth tightly, the wedges are made into equal perimeters of each section. In order to achieve this purpose, the difference in the height direction of the wedge blocks is used to compensate the different lengths of the original cross-section curves. Select on the wedge as figure 2 The 6 sections shown, the section spacing is 40mm, the length of the section curve h1-h6 is calculated by CATIA ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com