Device for preventing ash from being accumulated in rear smoke channel of coal-fired boiler subjected to denitration transformation

A technology of denitrification transformation and tail flue, which is applied in the direction of combustion air/fuel supply, combustion method, combustion control, etc., can solve the problem of excessive ash accumulation in the vertical section of the boiler economizer outlet when it turns to the horizontal section, and achieves The construction volume and investment are small, the structure is simple, and the effect of small device structure size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is described in further detail below in conjunction with accompanying drawing:

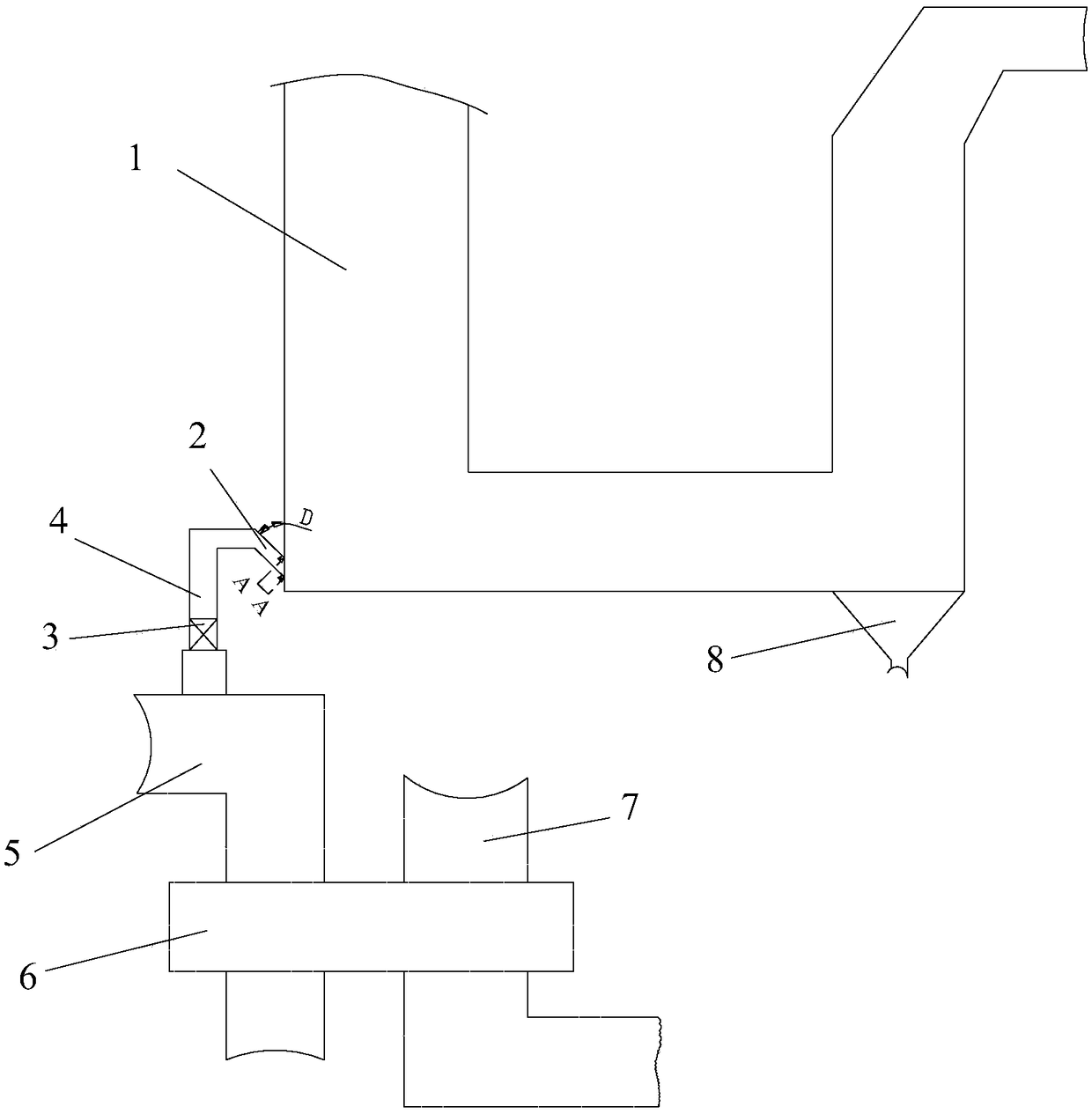

[0018] see figure 1 , a device for preventing soot accumulation in the tail flue of a coal-fired boiler after denitrification transformation, including an economizer outlet vertical flue 1, an air supply pipe 2, a pneumatic control valve 3, a bypass air duct 4, and a hot primary air duct 5 , Air preheater 6, air preheater inlet flue 7, ash hopper 8 and rectangular spout 9.

[0019] A bypass air duct 4 is externally connected to the hot primary air duct 5, and a pneumatic control valve 3 is arranged on the bypass air duct 4 to regulate the flow of the hot primary air entering the air supply duct 2; Road 1 is close to the horizontal flue, and a row of rectangular nozzles 9 is arranged in the width direction of the furnace. The hot primary air is injected into the corner of the vertical flue to the horizontal flue through the rectangular nozzles, thereby increasing the g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com