Exhaust funnel silencer

A muffler and exhaust pipe technology, applied in the field of auto parts, can solve the problems of poor noise reduction effect, and achieve the effect of reducing impact, reducing noise, and reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

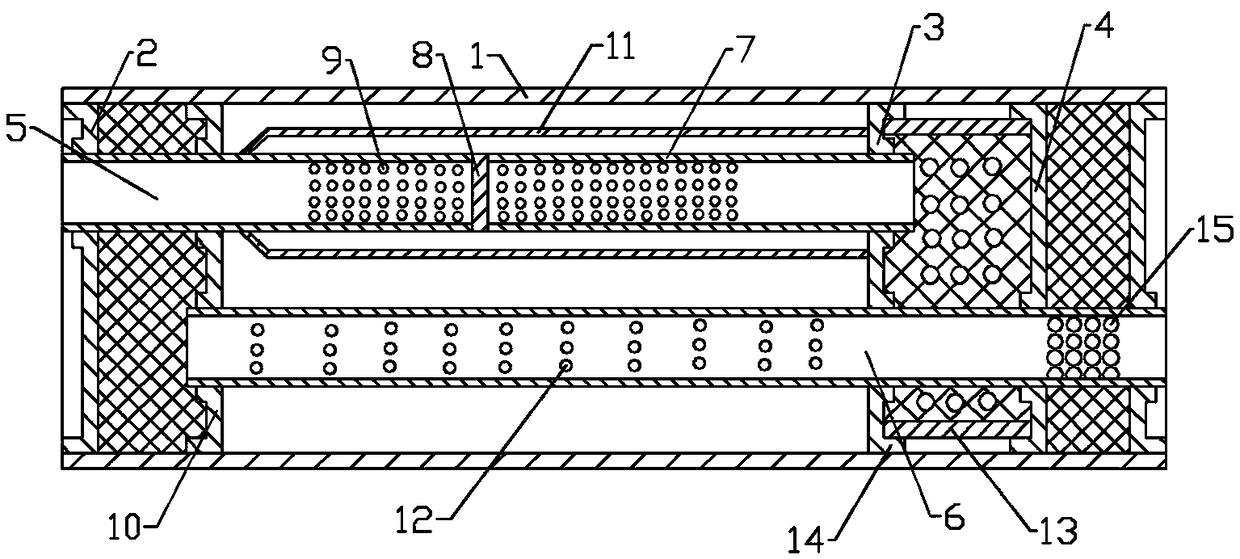

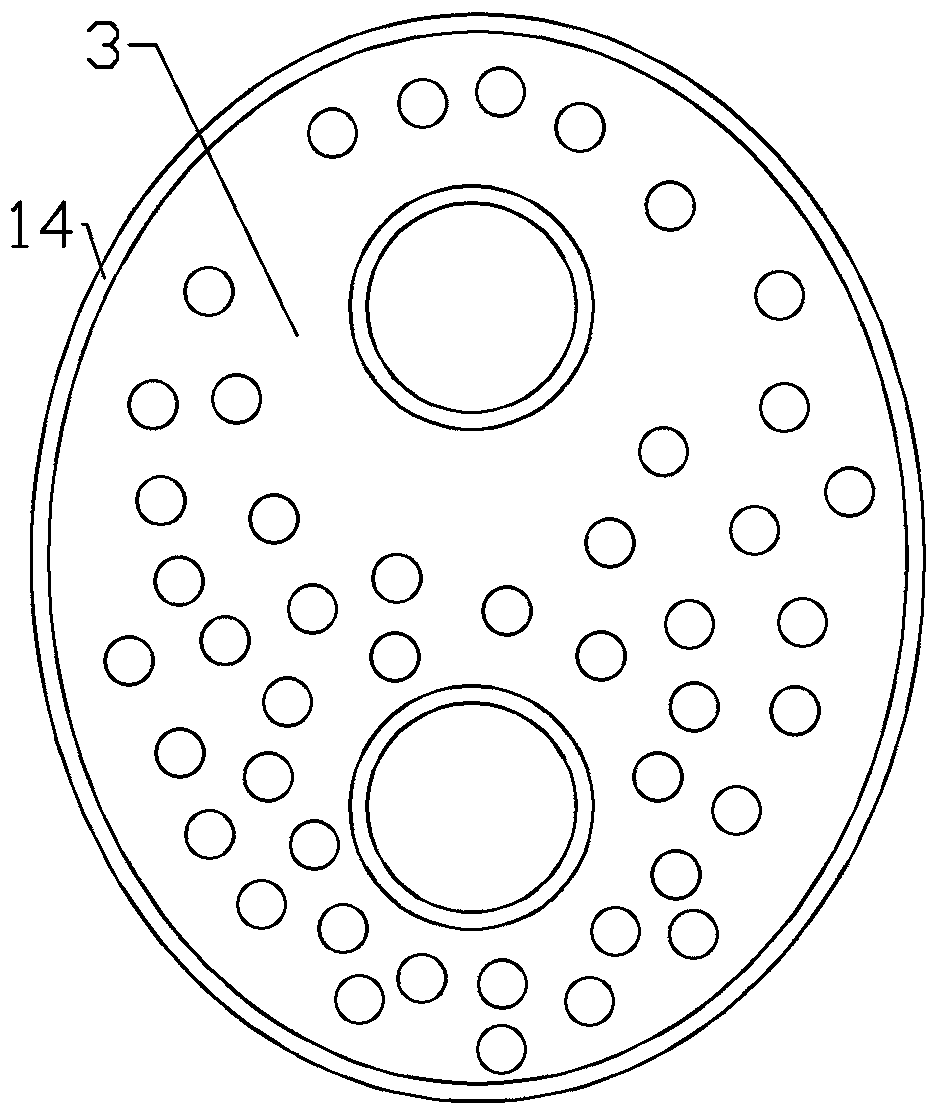

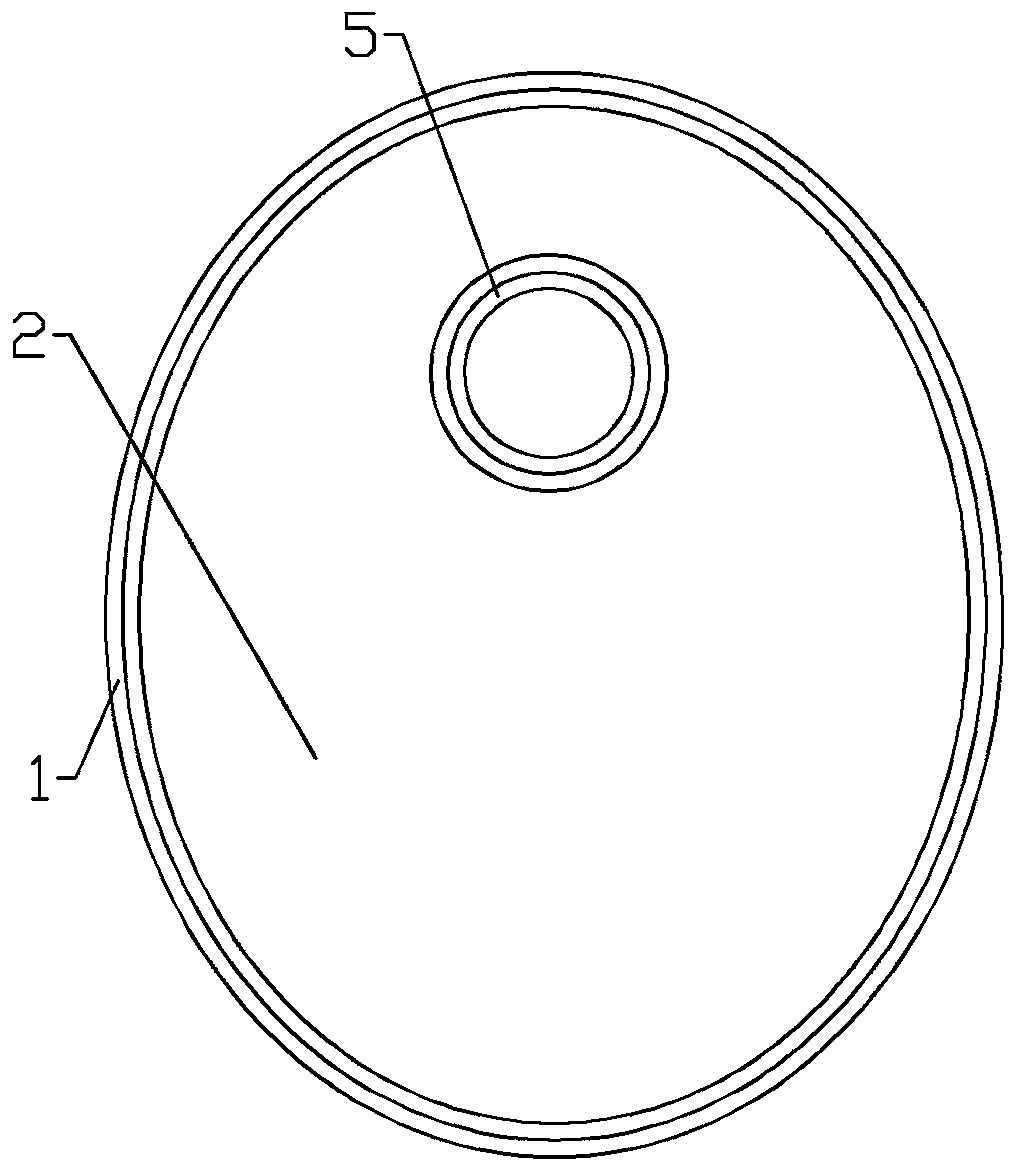

[0018] Such as Figure 1-3 As shown, a muffler for an exhaust tube includes a cylinder body 1 with an elliptical cross-section. The cylinder body 1 is surrounded and welded by stainless steel with a thickness of 2-3 mm. End caps 2 are sealed and welded at both ends of the cylinder body 1. The two ends of the body 1 are respectively connected with an intake pipe 5 and an exhaust pipe 6. The right end of the intake pipe 5 extends into the cylinder body 1 and has air holes 9 arranged in rows and columns on the wall. The right end of the intake pipe 5 is sealed and welded with a baffle plate 8. The right end of the trachea 5 is also coaxially connected with a transition pipe 7, the diameter of the air intake pipe 5 is the same as that of the transition pipe 7, and the wall at the left end of the transition pipe 7 is also provided with air holes in rows and columns, and the junction of the air intake pipe 5 and the transition pipe 7 is also covered with a The resonance tube 11, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com