Dust falling device for tunnel construction

A dust suppression device and tunnel construction technology, which is applied in safety devices, dust prevention, mining equipment, etc., can solve the problems of endangering the health of workers and heavy workload of workers, and achieve the effect of saving manpower and being easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

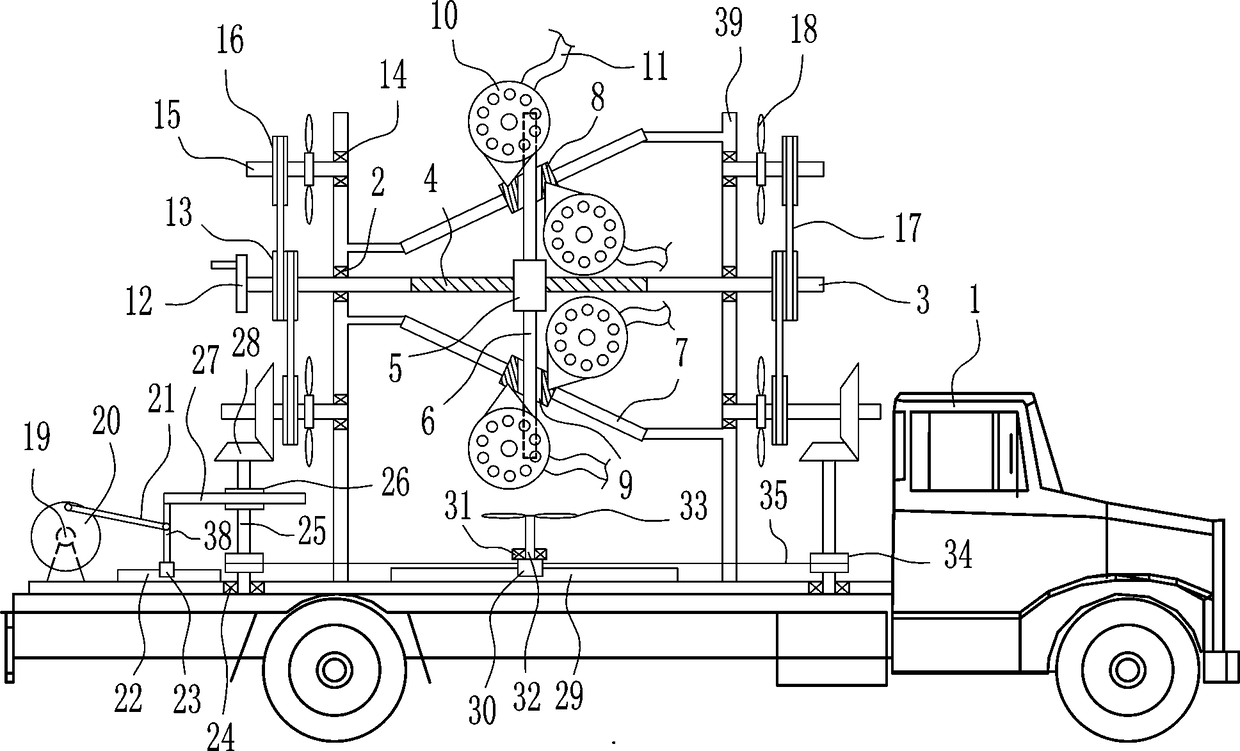

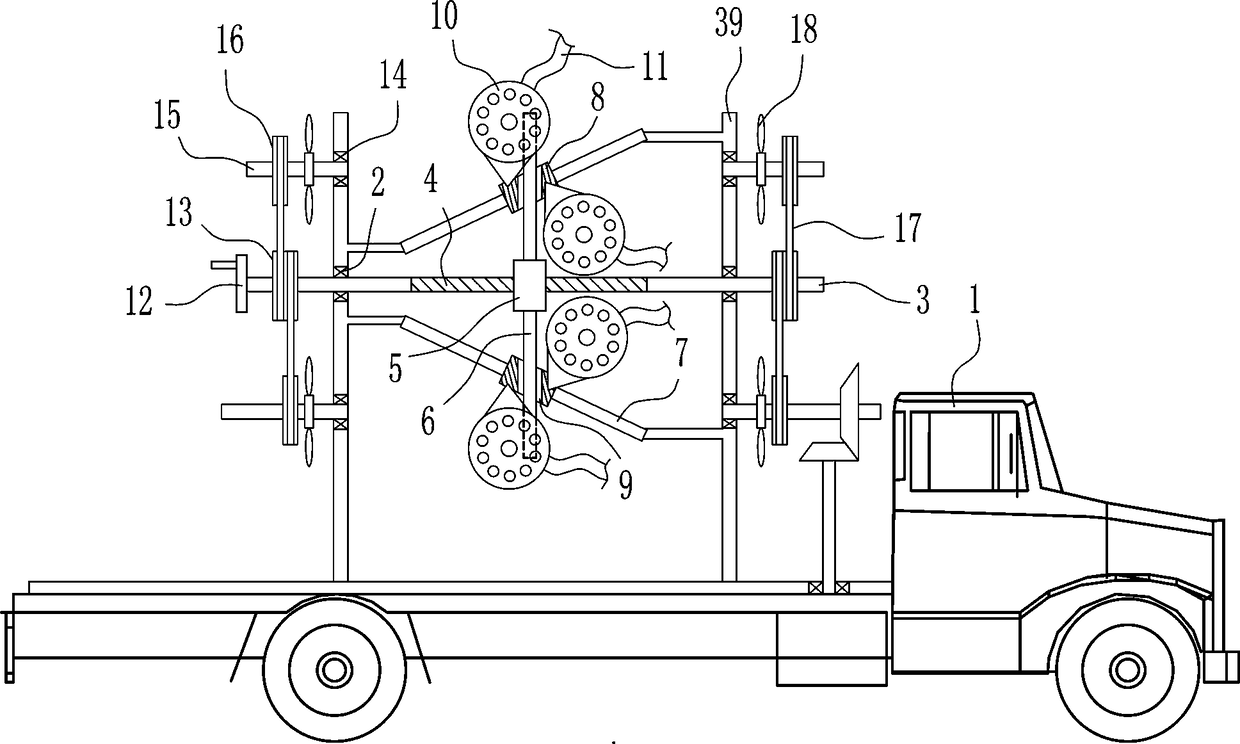

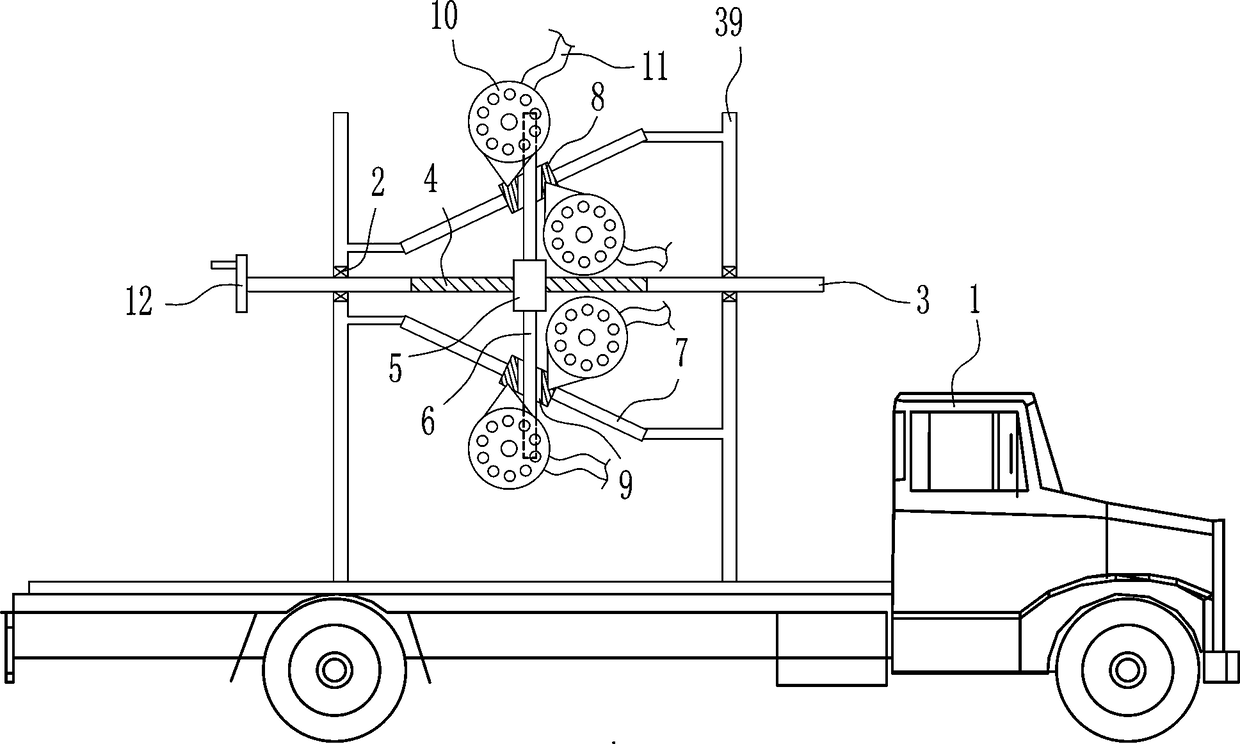

[0027] A dust suppression device for tunnel construction, such as Figure 1-5 As shown, it includes a transport vehicle 1, a first bearing seat 2, a first rotating rod 3, a threaded rod 4, a nut 5, a moving rod 6, a guide rail 7, a guide sleeve 8, a nozzle 10, a water pipe 11, a handle 12 and a mounting frame 39. Mounting frames 39 are connected to the left and right sides of the top of the transport vehicle 1, and the upper parts of the mounting frames 39 on the left and right sides are connected to the first bearing housing 2, and the first rotating rod 3 is connected to the first bearing housing 2. A threaded rod 4 is connected between the first rotating rods 3, a nut 5 is connected to the threaded rod 4, the upper and lower sides of the nut 5 are connected with a moving rod 6, and the upper and lower parts of the mounting frame 39 on the left and right sides are connected There is a guide rail 7, the threaded rod 4 is located between the guide rails 7, a guide sleeve 8 is s...

Embodiment 2

[0029] A dust suppression device for tunnel construction, such as Figure 1-5 As shown, it includes a transport vehicle 1, a first bearing seat 2, a first rotating rod 3, a threaded rod 4, a nut 5, a moving rod 6, a guide rail 7, a guide sleeve 8, a nozzle 10, a water pipe 11, a handle 12 and a mounting frame 39. Mounting frames 39 are connected to the left and right sides of the top of the transport vehicle 1, and the upper parts of the mounting frames 39 on the left and right sides are connected to the first bearing housing 2, and the first rotating rod 3 is connected to the first bearing housing 2. A threaded rod 4 is connected between the first rotating rods 3, a nut 5 is connected to the threaded rod 4, the upper and lower sides of the nut 5 are connected with a moving rod 6, and the upper and lower parts of the mounting frame 39 on the left and right sides are connected There is a guide rail 7, the threaded rod 4 is located between the guide rails 7, a guide sleeve 8 is s...

Embodiment 3

[0032] A dust suppression device for tunnel construction, such as Figure 1-5 As shown, it includes a transport vehicle 1, a first bearing seat 2, a first rotating rod 3, a threaded rod 4, a nut 5, a moving rod 6, a guide rail 7, a guide sleeve 8, a nozzle 10, a water pipe 11, a handle 12 and a mounting frame 39. Mounting frames 39 are connected to the left and right sides of the top of the transport vehicle 1, and the upper parts of the mounting frames 39 on the left and right sides are connected to the first bearing housing 2, and the first rotating rod 3 is connected to the first bearing housing 2. A threaded rod 4 is connected between the first rotating rods 3, a nut 5 is connected to the threaded rod 4, the upper and lower sides of the nut 5 are connected with a moving rod 6, and the upper and lower parts of the mounting frame 39 on the left and right sides are connected There is a guide rail 7, the threaded rod 4 is located between the guide rails 7, a guide sleeve 8 is s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com