Box modularized haven wharf

A safe haven and modular technology, applied in the field of safe harbor wharf, can solve problems such as hazards, achieve the effect of rapid construction, avoid damage to the marine environment, and avoid pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

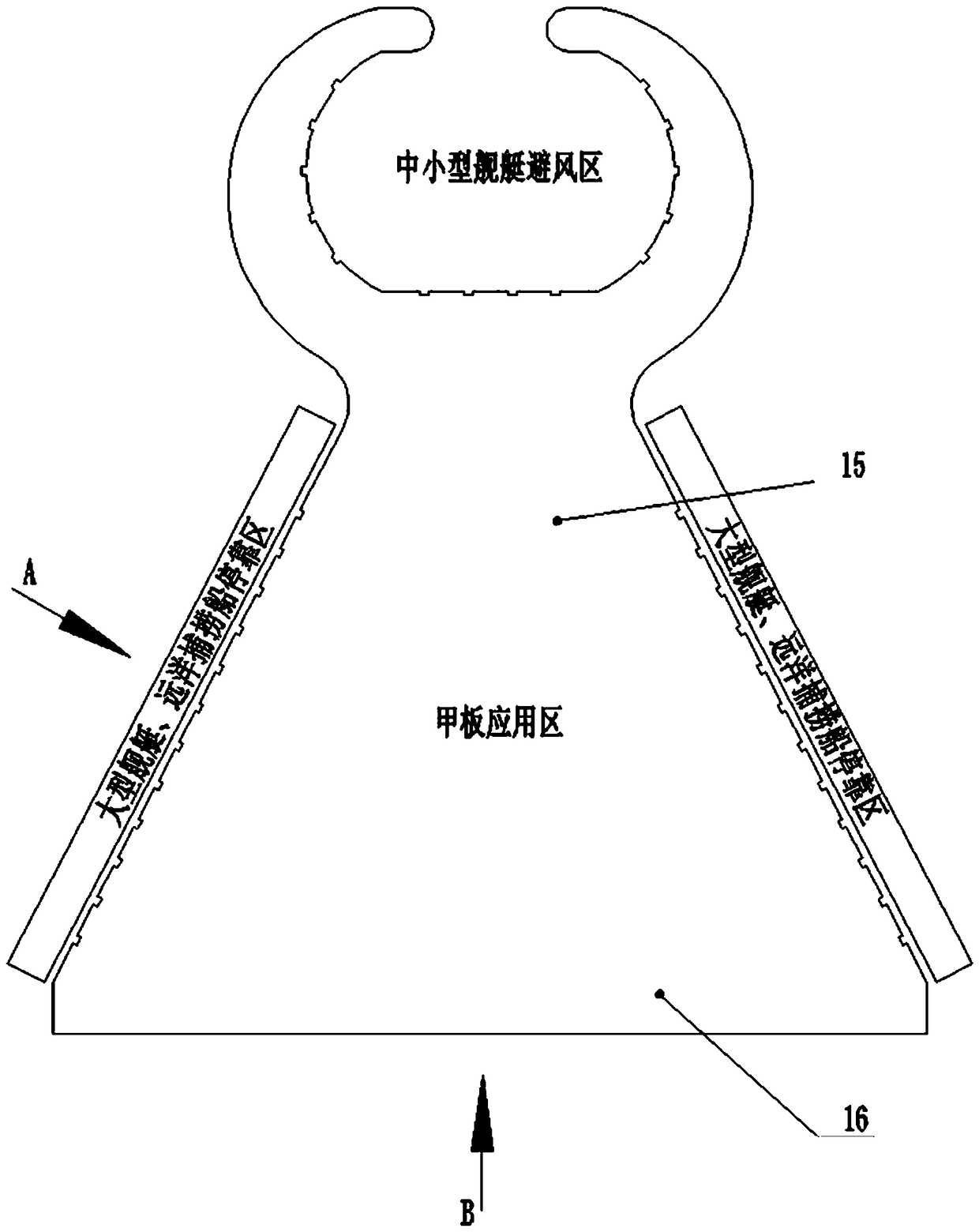

[0023] Specific implementation mode one: as Figure 1-Figure 3 , Figure 7 , Figure 8 As shown, this embodiment discloses a box-body modular safe harbor wharf, which is characterized in that: its composition includes a wharf main body 15 and a near-shore end main body 16, and one end of the near-shore end main body 16 is connected to the land (or the near-shore end main body 16 connected to the land through a pontoon), the other end of the near-shore main body 16 is detachably and fixedly connected to one end of the wharf main body 15, and the wharf main body 15 is opposite to the seabed through a plurality of lower box piles 11 that can move up and down. Fixed, the main body 16 near the shore is relatively fixed to the seabed through a plurality of piles 18 at the near shore that can move up and down. The end of the wharf main body 15 away from the land is provided with a concave area. A sheltered area for small ships.

specific Embodiment approach 2

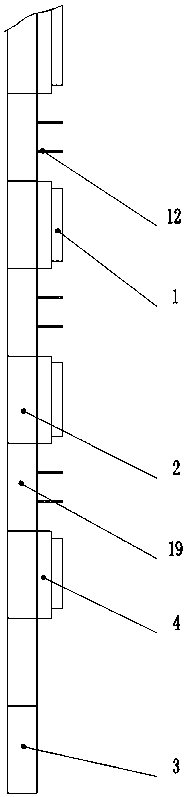

[0024] Specific implementation mode two: as Figure 2-Figure 4 , Figure 5 , Figure 7 , Figure 8 As shown, this embodiment is a further description of specific embodiment one. The wharf main body 15 includes a plurality of main body upper boxes 19, a plurality of main body upper boxes 2, and a plurality of main body lower boxes 4; A plurality of buoys 1, a plurality of lower box piles 11, a plurality of columns 12 of the flood discharge section, a plurality of pile locking mechanisms 1 and a plurality of pile locking mechanisms 2;

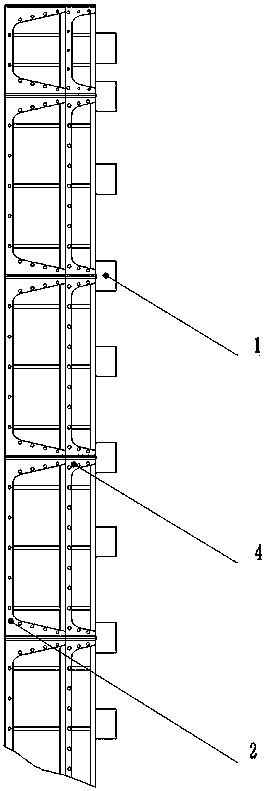

[0025] The sidewalls of the upper casings 19 of the plurality of main bodies, the upper casings 2 of the plurality of main bodies and the lower casings 4 of the plurality of main bodies are all provided with hollow structures, and the upper casings 2 2 of the plurality of main bodies are tiled and arranged, and each A main body lower box 4 is fixed below the upper main body box two 2, and a main body upper box one 19 is arranged between every ...

specific Embodiment approach 3

[0029] Specific implementation mode three: as figure 2 , image 3 , Figure 7 , Figure 8 As shown, this embodiment is a further description of the second specific embodiment. Each of the pile locking mechanisms includes a lead screw 13 and a screw nut 20; the bottom plate of each main body lower box 4, The top plate and the bottom plate of the main body upper box body 2 fixedly connected with the described main body lower box body 4 are all provided with a plurality of through holes one, and are arranged on the bottom plate of the main body lower box body 4 and a plurality of through holes on the top plate One is arranged in correspondence with the plurality of through holes arranged on the bottom plate of the upper box body 2 of the main body one by one, and each of the three corresponding through holes one is fixed and inserted into the sleeve one, and the plurality of sleeves One by one slides and penetrates into the lower box piles 11, the upper ends of the plurality ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com