Far-infrared warm-keeping flame-retardant functional wadding and preparation method thereof

A technology of far-infrared and far-infrared materials, applied in coatings, non-woven fabrics, textiles, and papermaking, can solve the problem of inability to have both flame retardancy and far-infrared properties, poor thermal performance, and flakes that cannot simultaneously possess warmth, Flame retardant and far-infrared emission functions and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

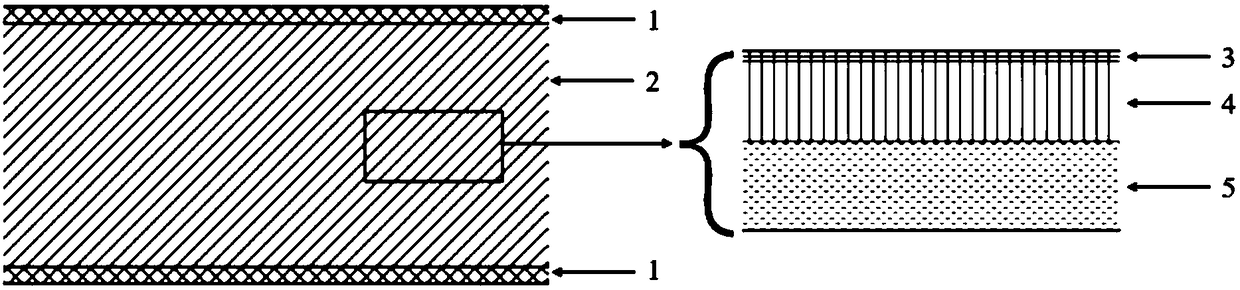

[0073] Example 1. Preparation of far-infrared thermal insulation and flame-retardant functional flakes

[0074] 1. Preparation method

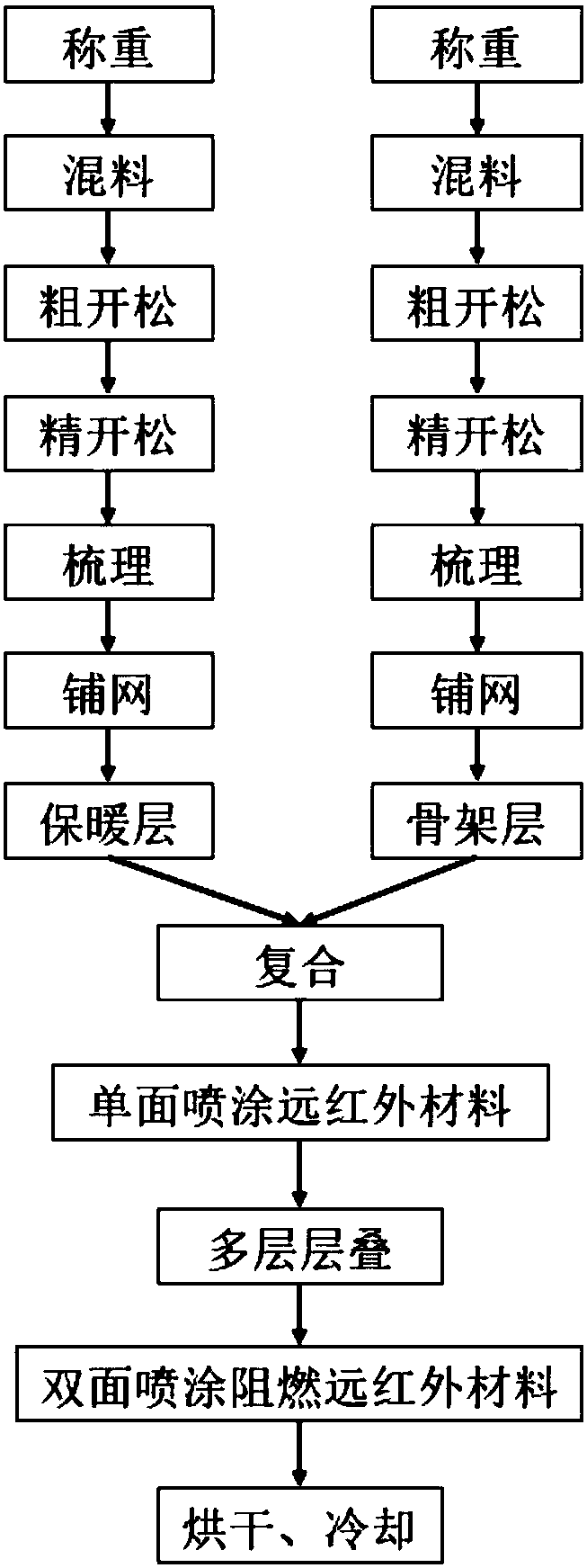

[0075] according to figure 2 The flow chart shown in the preparation of far-infrared heat preservation and flame-retardant functional wadding, the steps are as follows:

[0076] 1. Preparation of thermal insulation layer

[0077] Prepare the thermal insulation layer according to the following steps: weighing raw materials → uniform mixing of ingredients → coarse opening and loosening and mixing → fine opening and loosening and mixing → carding → laying net

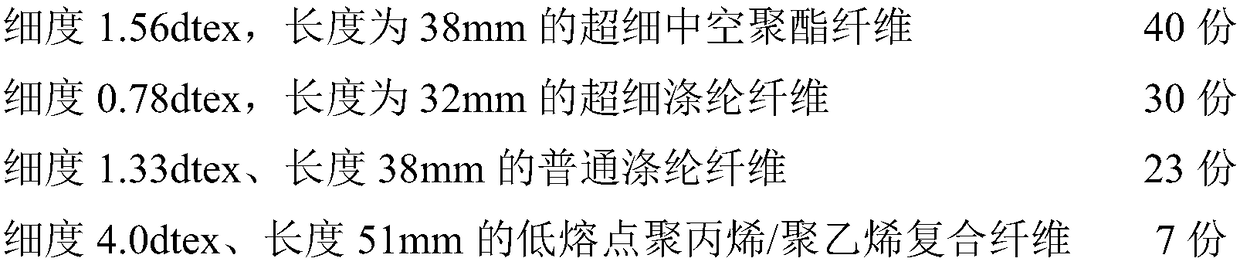

[0078] Wherein, in the step of weighing the raw materials and the step of uniformly mixing and mixing the materials, the raw materials in the following parts by weight are mixed with a plucking machine to form a sufficient mixture.

[0079]

[0080] Among them, in the carding step and the web laying step, the air-pressure carding device is used to fully card the mixed material, and ...

Embodiment 2

[0103] Example 2, preparation of far-infrared thermal insulation and flame-retardant functional flakes

[0104] According to the steps in Example 1, the far-infrared thermal insulation and flame-retardant functional flakes were prepared, and the modifications were as follows:

[0105] 1. Modify the weight ratio of each fiber in the thermal insulation layer and the skeleton layer to the following ratio:

[0106] Warm Layer Ratio:

[0107]

[0108] Skeleton layer ratio:

[0109]

[0110] 2. The far-infrared heat preservation and flame retardant flakes are preferably laminated with 10 layers of composite heat preservation layers.

[0111] Particularly, in this embodiment, the grammage of the thermal insulation layer is 8g / ㎡.

[0112] The weight of the skeleton layer is 5.5g / ㎡.

[0113] The weight of the far-infrared layer is 0.2g / ㎡.

[0114] The weight of the composite thermal insulation layer is 13.5g / ㎡.

[0115] The weight of the far infrared flame retardant layer is ...

Embodiment 3

[0121] Example 3, preparation of far-infrared heat preservation and flame-retardant functional flakes

[0122] According to the steps in Example 1, the far-infrared thermal insulation and flame-retardant functional flakes were prepared, and the modifications were as follows:

[0123] 1. Modify the weight ratio of each fiber in the thermal insulation layer and the skeleton layer to the following ratio:

[0124] Warm Layer Ratio:

[0125]

[0126] Skeleton layer ratio:

[0127]

[0128] 2. The far-infrared heat preservation and flame retardant flakes are preferably laminated with 8 layers of composite heat preservation layers.

[0129] Particularly, in this embodiment, the grammage of the thermal insulation layer is 7g / ㎡.

[0130] The weight of the skeleton layer is 5g / ㎡.

[0131] Far-infrared layer weight 0.3g / m 2 .

[0132] The weight of the composite thermal insulation layer is 12g / ㎡.

[0133] The weight of the far infrared flame retardant layer is 4g / ㎡.

[0134...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com