Pneumatic-based electrospinning device

A technology of electrospinning and air supply device, applied in textiles and papermaking, filament/thread forming, fiber processing, etc., can solve the problems of unstable jet flow, affecting electrospinning, waste of resources, etc. Reduce charge interference, reduce the effect of charge interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with drawings and embodiments.

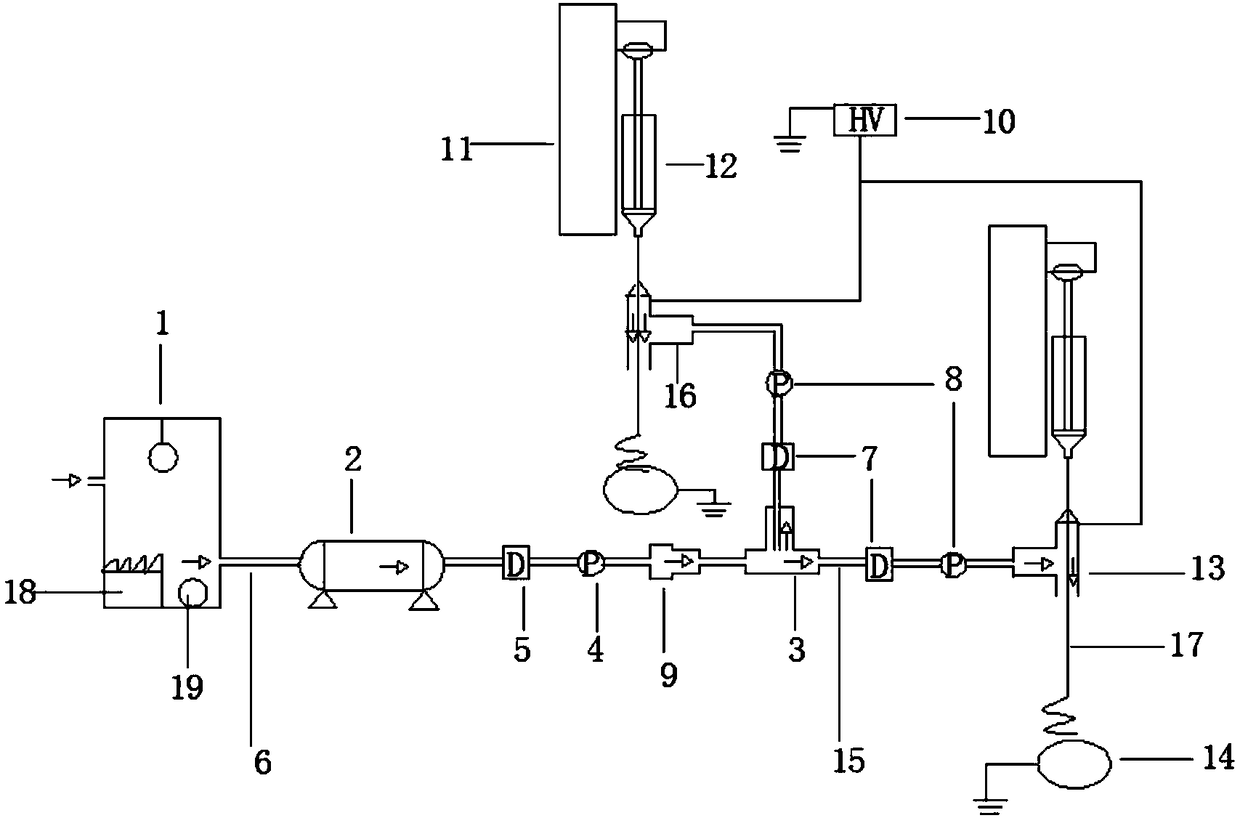

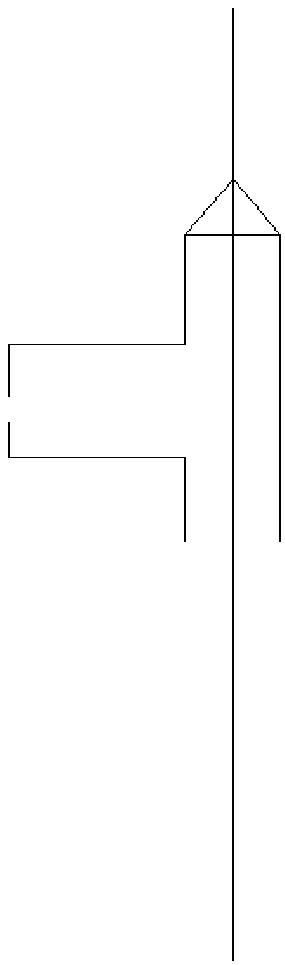

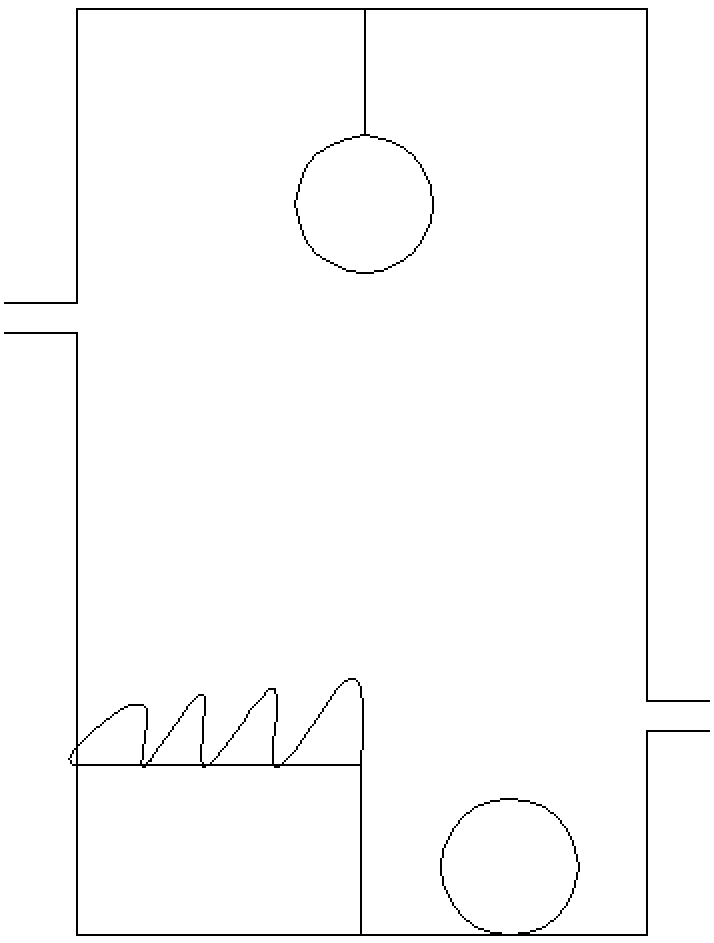

[0029] see Figure 1~3 , the embodiment of the present invention is equipped with a gas supply device, a gas distribution device and a spray device;

[0030] The gas supply device includes: a gas drying device 1 connected in sequence, an air compressor 2, and a gas conduit adapter device 9; the gas supply devices are connected through a gas conduit 6 with an inner diameter of 6 to 8 mm; A pressure regulating valve 5 and a gas pressure gauge 4 are arranged between the gas conduit adapters 9 . In the gas drying device 1 , a desiccant 19 and a temperature raising device 18 are provided inside.

[0031] The gas distribution device 3 connected to the gas conduit adapter device 9 is connected to the injection device; the gas supply device and the injection device are connected through a gas conduit 15 with an inner diameter of 3-5 mm. An auxiliary pressure regulating valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com