Preparation technology of highland barley sesame oil

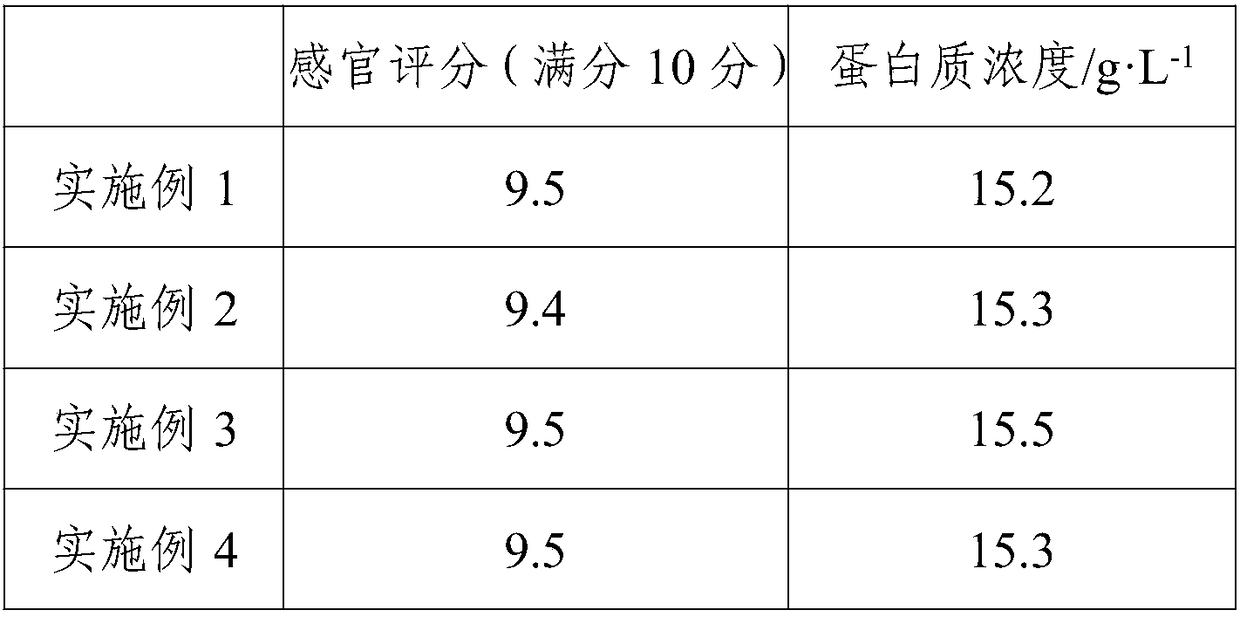

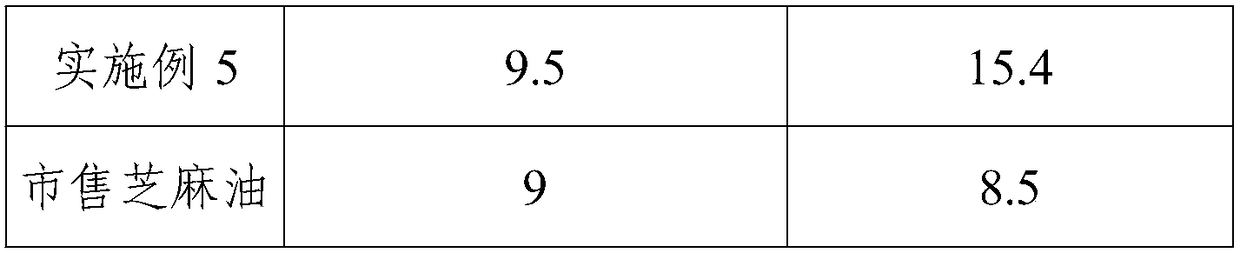

A preparation process and a technology for sesame oil, applied in the field of preparation technology of highland barley sesame oil, can solve the problems of low nutritional value, poor sensory properties, poor stability of finished products, etc., and achieve the effects of high nutritional value, stable protein composition and rich taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A kind of highland barley sesame oil, the preparation process comprises the following steps:

[0025] (1) Take 350g of high-quality sesame seeds, screen them with a magnetic separator, remove moldy, discolored, and imperfect seeds, cook them under high pressure at 110°C for 1 min at a material-to-water ratio of 1:2, and take them out for later use;

[0026] (2) Take 40g of high-quality highland barley, make a mixed solution with a material-to-liquid ratio of 1:20, add a weak base solution to adjust the pH to 6.5, and add 0.02% glucoamylase and liquefaction enzyme at the same time at 80°C to enzymatically hydrolyze 5 Hour;

[0027] (3) Add the cooked sesame into the mixed solution of (2), ultrasonically treat for 10 minutes, add 0.2% composite stabilizer, stir evenly at high speed, and filter to remove the filtrate;

[0028] (4) Put the material obtained in step (3) into a juice extractor, adjust the temperature to 30° C., squeeze at a low temperature, and then centrifu...

Embodiment 2

[0030] A kind of highland barley sesame oil, the preparation process comprises the following steps:

[0031] (1) Take 400g of high-quality sesame seeds, pass through the magnetic separator to filter, remove moldy grains, discolored grains, and imperfect grains, cook under high pressure at 110°C for 2 minutes with a material-to-water ratio of 1:2, and take them out for later use;

[0032] (2) Take 60g of high-quality highland barley, make a mixed solution with a material-to-liquid ratio of 1:20, add a weak base solution to adjust the pH to 6.0, and add 0.02% glucoamylase and liquefaction enzyme at the same time at 75°C to enzymolyze 4 Hour;

[0033] (3) Add the cooked sesame into the mixed solution of (2), ultrasonically treat for 15 minutes, add 0.2% composite stabilizer, stir evenly at high speed, and filter to remove the filtrate;

[0034] (4) Put the material obtained in step (3) into a juice extractor, adjust the temperature to 25° C., press at a low temperature, and then...

Embodiment 3

[0036] A highland barley sesame oil, the preparation process comprises the following steps:

[0037] (1) Take 350g of high-quality sesame seeds, pass through a magnetic separator to filter out moldy grains, discolored grains, and imperfect grains, cook under high pressure at 110°C for 2 minutes with a material-to-water ratio of 1:2, and take them out for later use;

[0038] (2) Take 40g of high-quality highland barley, make a mixed solution with a material-to-liquid ratio of 1:20, add a weak base solution to adjust the pH to 6.5, and add 0.02% glucoamylase and liquefaction enzyme at the same time at 75°C to enzymatically hydrolyze 5 Hour;

[0039] (3) Add the cooked sesame into the mixed solution of (2), ultrasonically treat for 10 minutes, add 0.2% composite stabilizer, stir evenly at high speed, and filter to remove the filtrate;

[0040] (4) Put the material obtained in step (3) into a juice extractor, adjust the temperature to 30° C., squeeze at a low temperature, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com