Automatic paper tape head searching and clamping mechanism for paper disc and control method

A paper tray and paper head technology, which is applied in the field of automatic paper tray finding and picking up paper head mechanism and control field, can solve the problems of inability to peel off, inaccurate paper finding, and inaccurate clamping, and achieves the effect of improving work efficiency and ensuring reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions of the present invention will be further described in detail below in conjunction with specific embodiments.

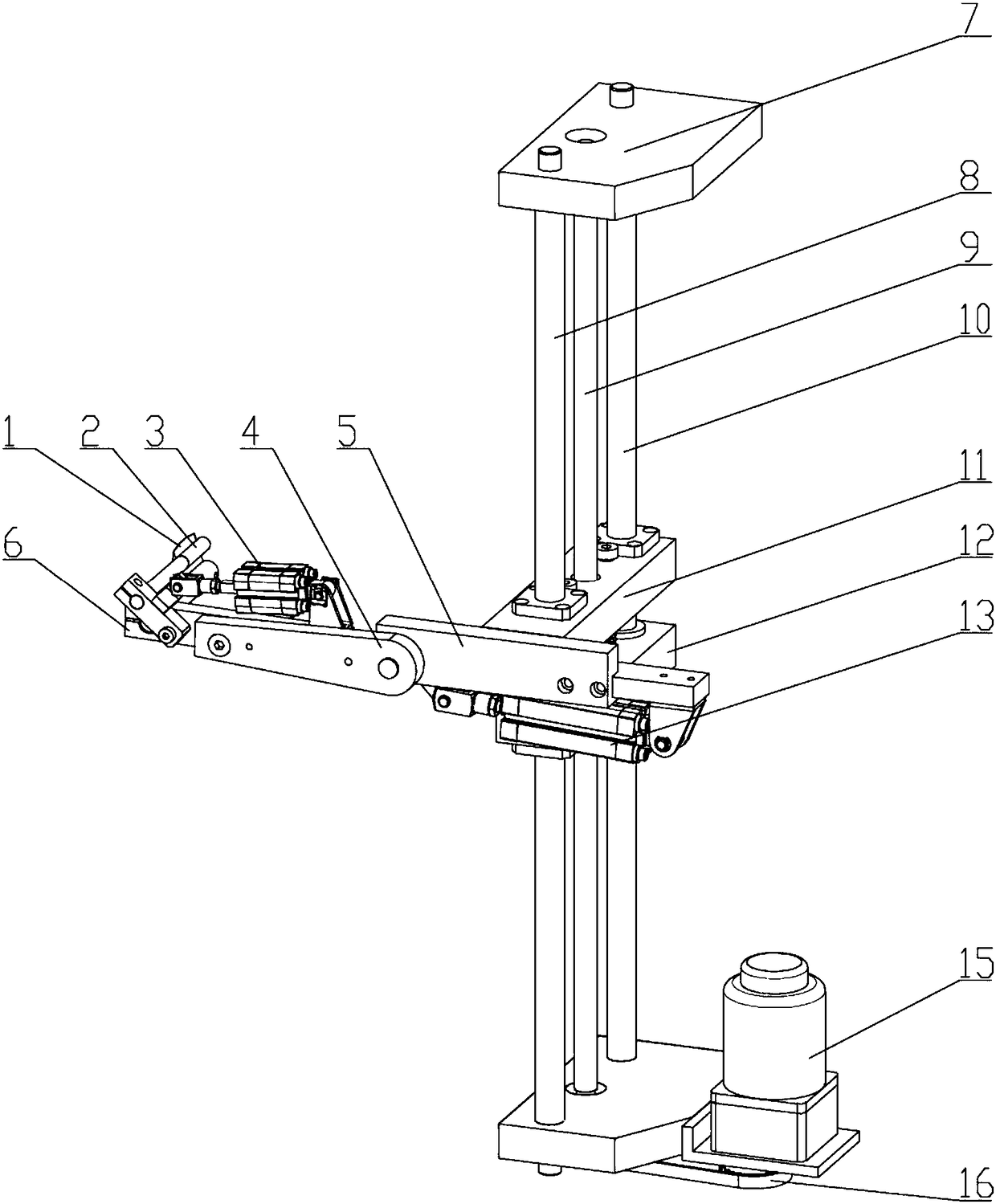

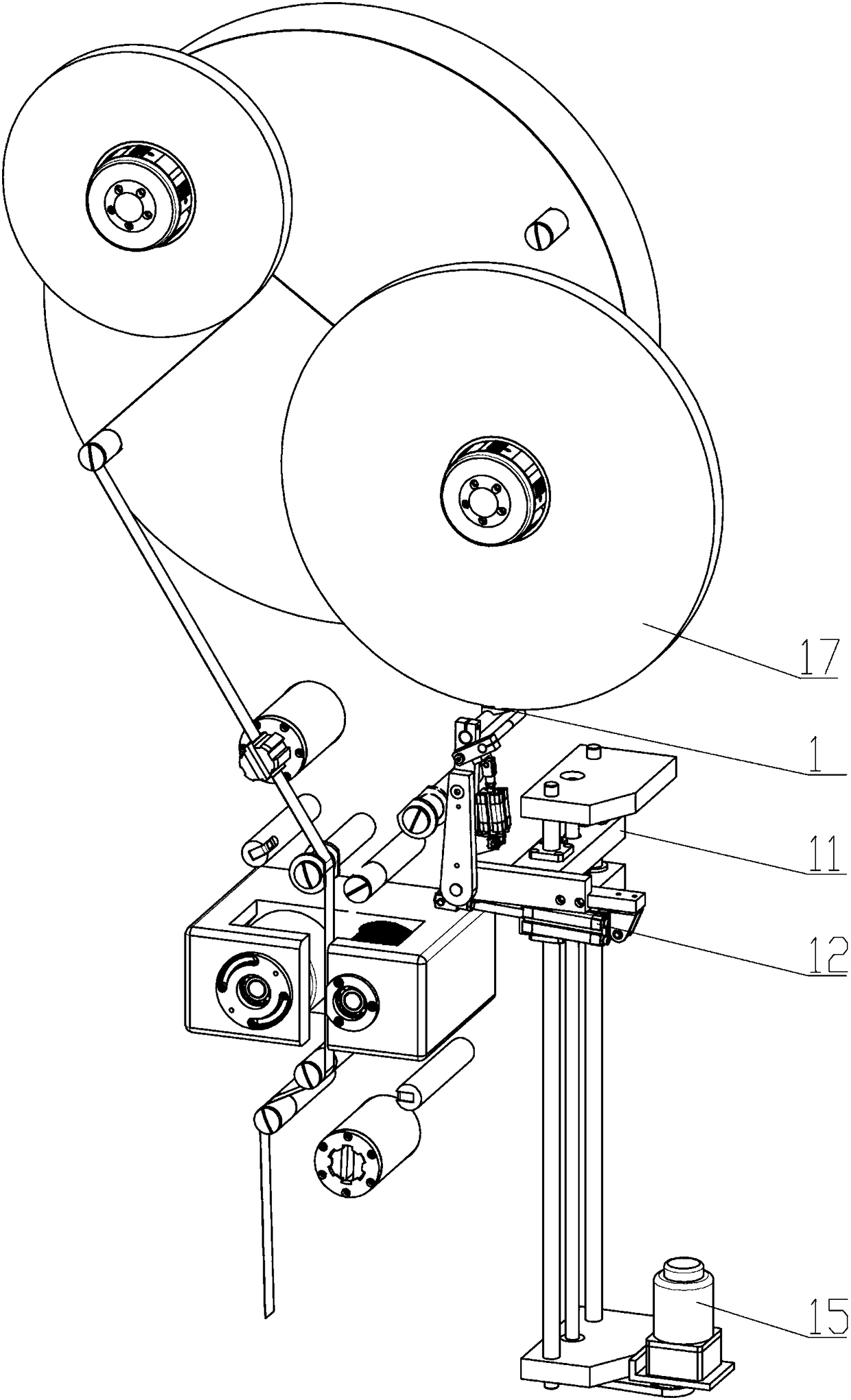

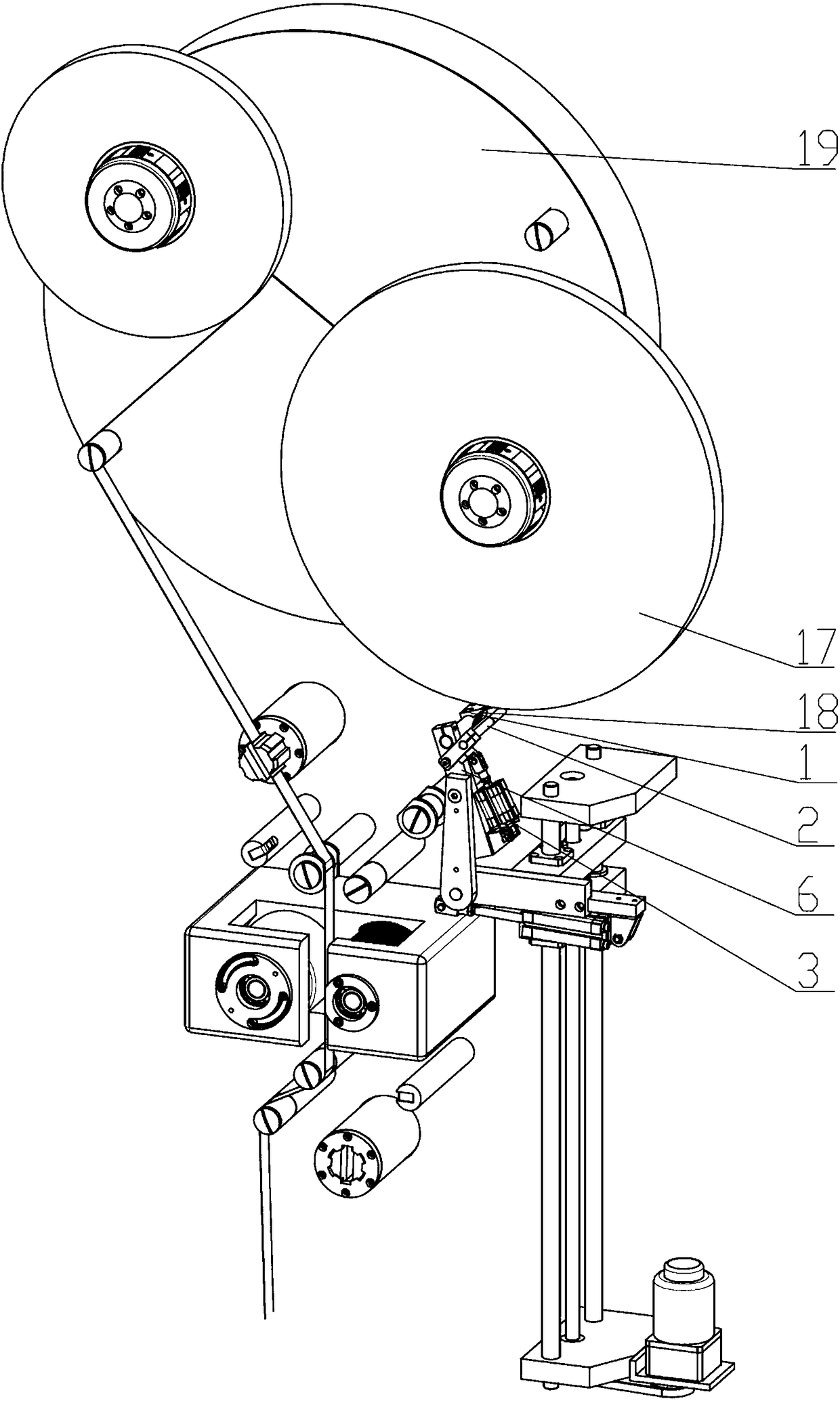

[0026] Such as figure 1 A mechanism for automatically finding and picking up the paper head of a paper tray as shown, includes a paper peeling blade 1, a paper clamping rod 2, a first cylinder 3, a connecting rod 4, a fixed rod 5, a floating connecting rod 6, a fixed plate 7, a first straight line Optical axis 8, screw mandrel 9, second linear optical axis 10, floating slider 11, lifting slider 12, second cylinder 13, motor 15, timing belt 16, the fixed plate 7 includes upper and lower two pieces, and A first linear optical axis 8, a screw rod 9 and a second linear optical axis 10 are fixedly connected between the two fixed plates 7, and the motor 15 is connected to a screw rod 9 through a timing belt 16, and the screw rod 9 is adapted to Connected with lifting slider 12, described lifting slider 12 is connected with floating slider 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com