Automatic cover opening and closing device for industrial container

A technology of automatic opening and closing, container cover, applied in the direction of cover, packaging, cover, etc., can solve the problems of poor screwing and opening reliability, high work intensity, unsuitable for manual operation, etc., to ensure reliability and reduce electrical appliances. effect of using

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

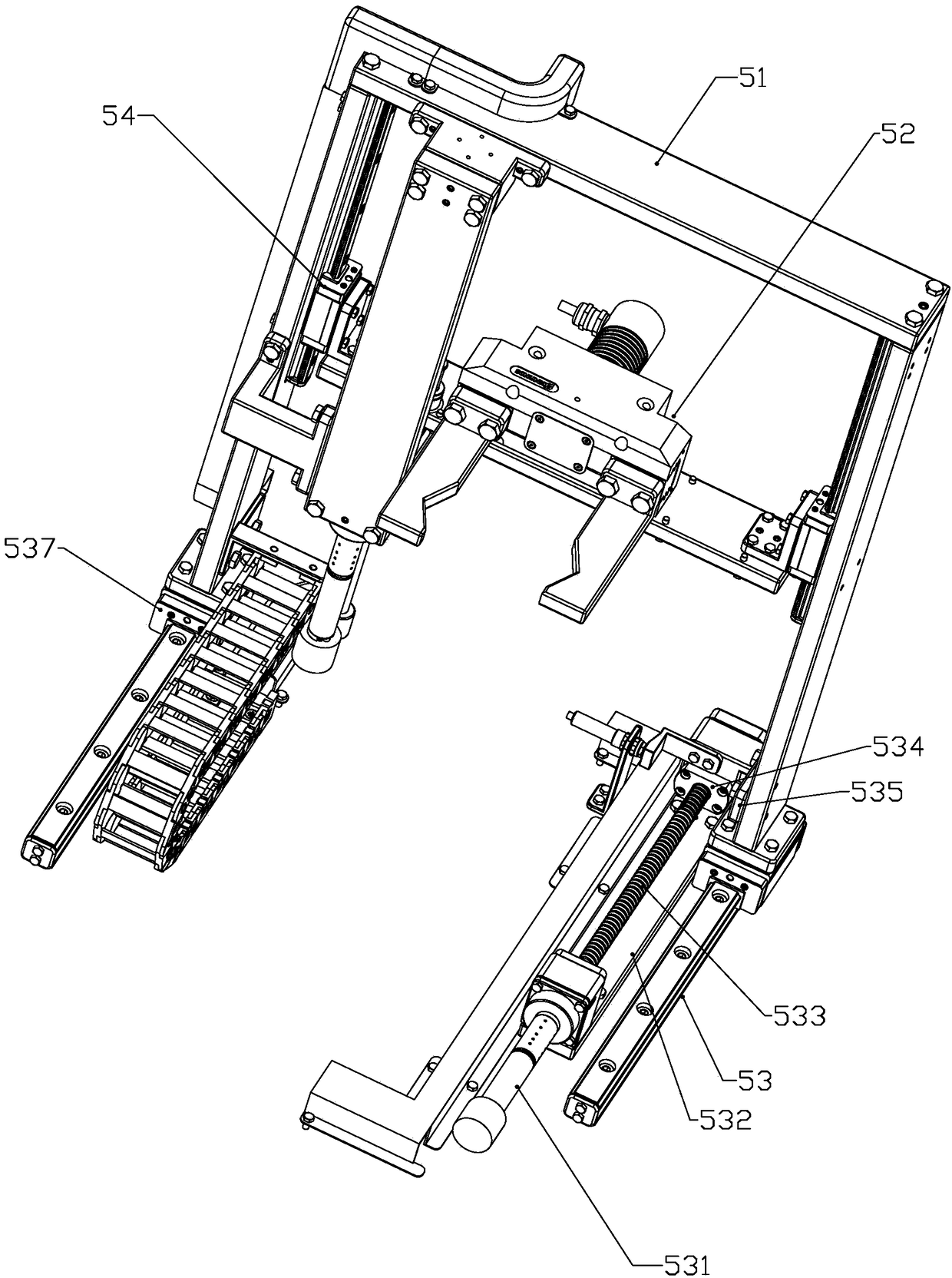

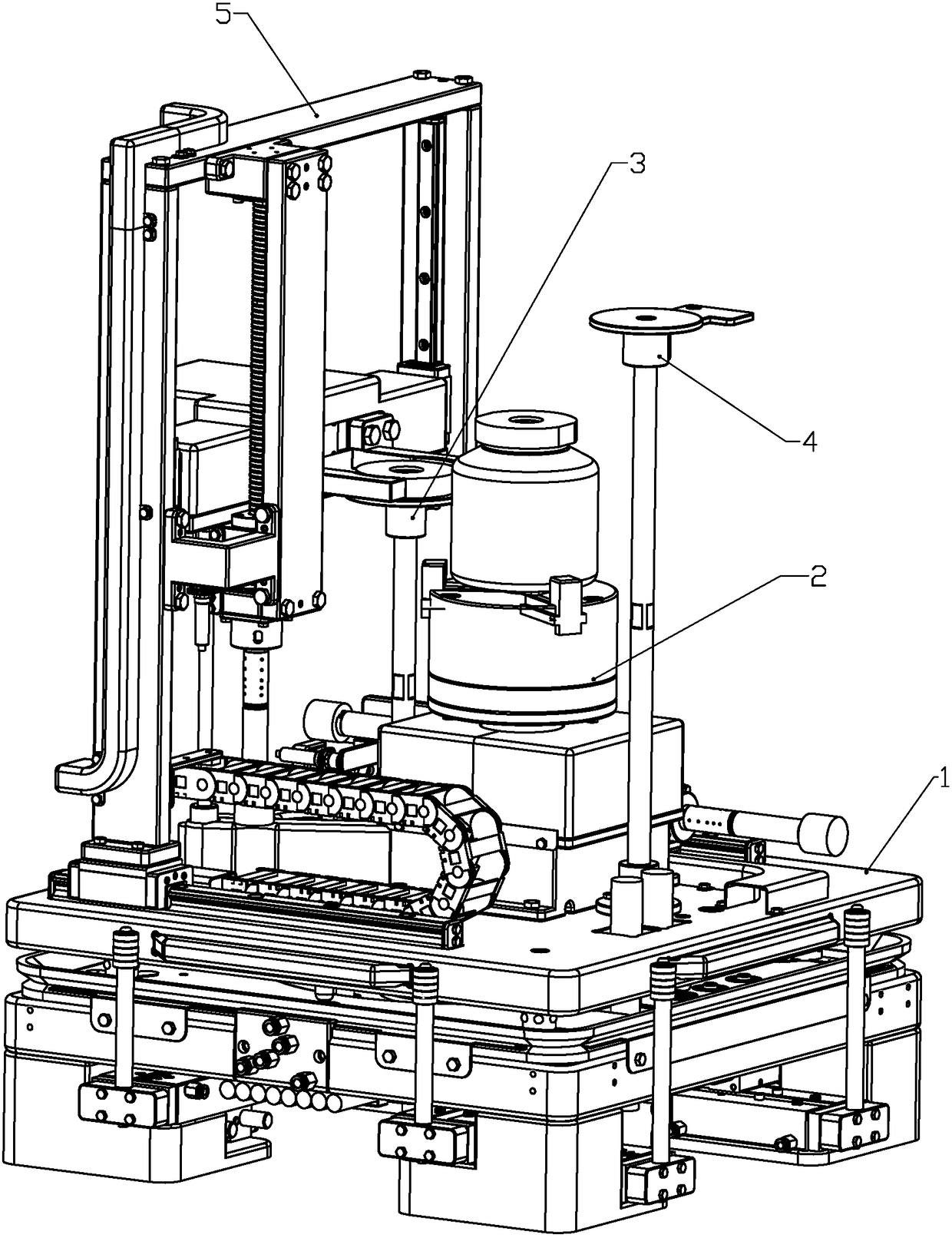

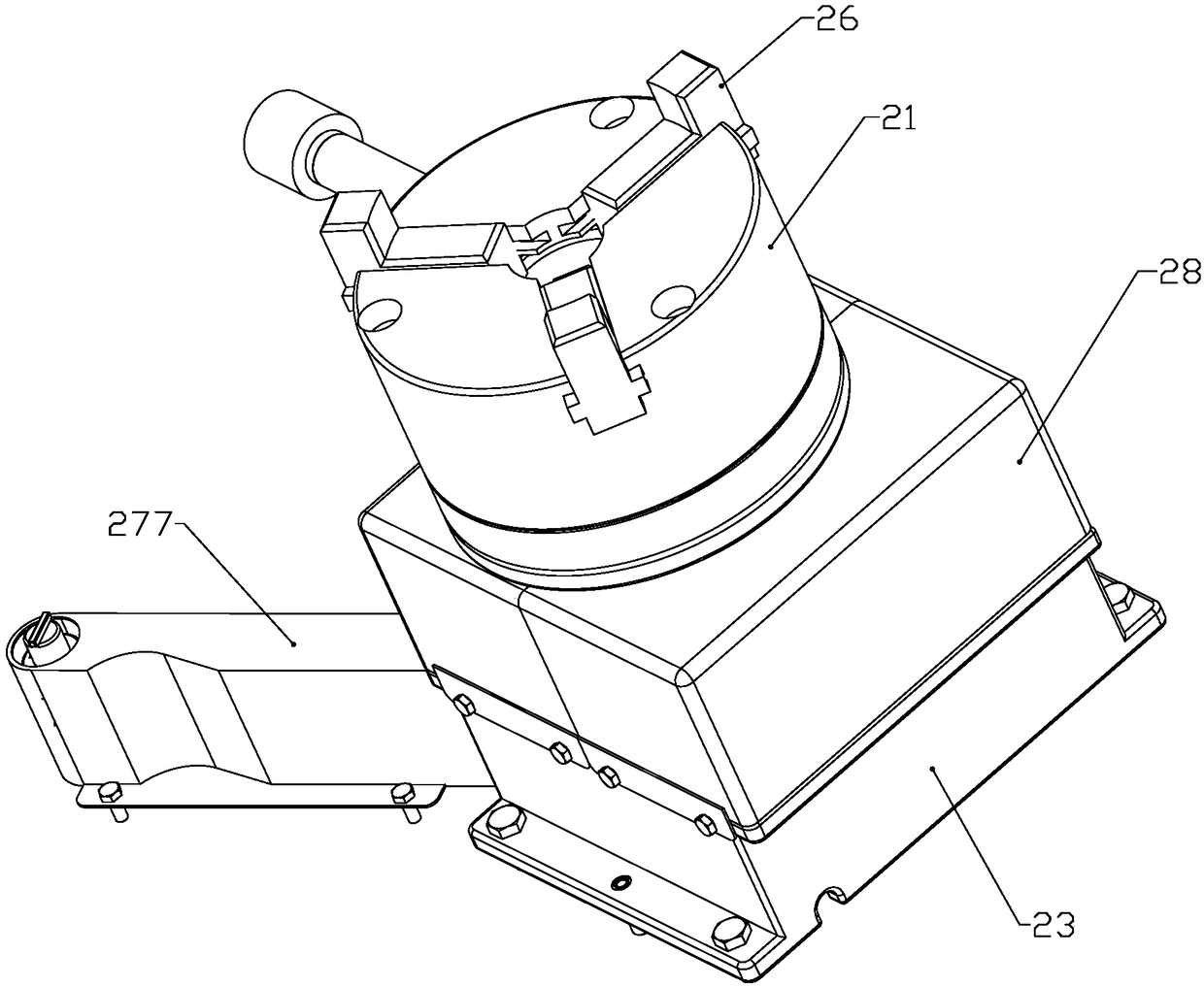

[0043] Refer to the attached figure 1 To attach Figure 15 The automatic lid opening and closing device for industrial containers of the present invention will be described in detail below.

[0044]The automatic lid opening and closing device for industrial containers of the present invention has a structure comprising a base 1, a container turntable mechanism 2, a container cover temporary storage seat 3, a funnel temporary storage seat 4, and an automatic clamping mechanism 5. The container turntable mechanism 2, container The cover temporary storage seat 3, the funnel temporary storage seat 4 and the automatic clamping mechanism 5 are respectively arranged on the base 1, and the container turntable mechanism 2 is located in the middle position of the upper part of the base 1, and the front and rear ends of the container turntable mechanism 2 are respectively provided with Funnel temporary storage seat 4 and container cover temporary storage seat 3.

[0045] The container ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com