High-voltage system circuit of new energy vehicle

A new energy vehicle and high-voltage system technology, applied in the field of new energy vehicles, to achieve the effect of prolonging the service life and saving charging energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

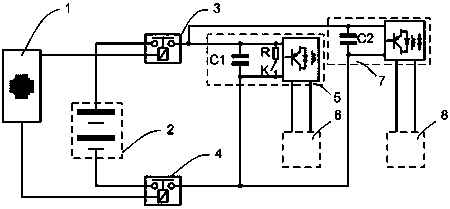

[0023] combined with figure 1 As shown, the high-voltage system circuit of the new energy vehicle of the present invention includes a control system 1 (the specific control function can be composed of a single or two or more controller combination), power battery 2, power relay 3, main negative relay 4, DC converter 5, low-voltage circuit system 6, vehicle charger 7 and mains power system 8. The DC converter 5 has a bidirectional conversion function or has a built-in independent capacitor self-charging circuit, and a controllable charge rapid discharge circuit is provided on the high-voltage DC side of the DC converter 5 (or the on-board charger 7), and the DC converter 5 and the on-board charging The circuit on the high-voltage DC side of the machine 7 is directly connected and shares one power supply relay 3 .

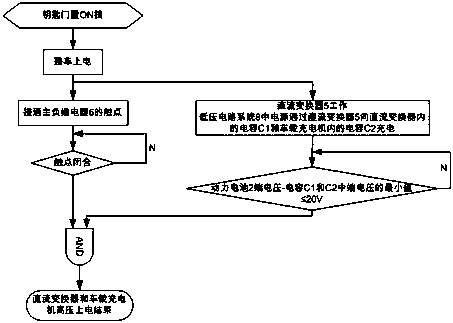

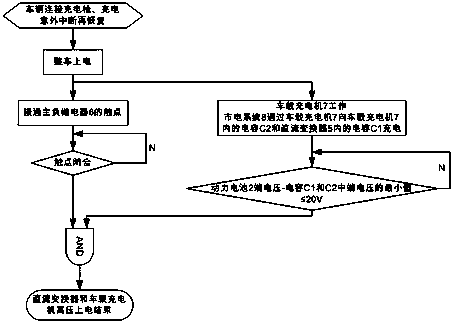

[0024] combined with figure 2 , attached image 3 And attached Figure 4 , the new energy vehicle high voltage system circuit of the present invention comprises...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com