Paintbrush cleaning machine

A technology for cleaning machines and brushes, applied in the field of cleaning machines, can solve the problems of slow cleaning speed, damage, damage to the brushes of the brushes, etc., and achieves the effect of fast cleaning speed and less damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

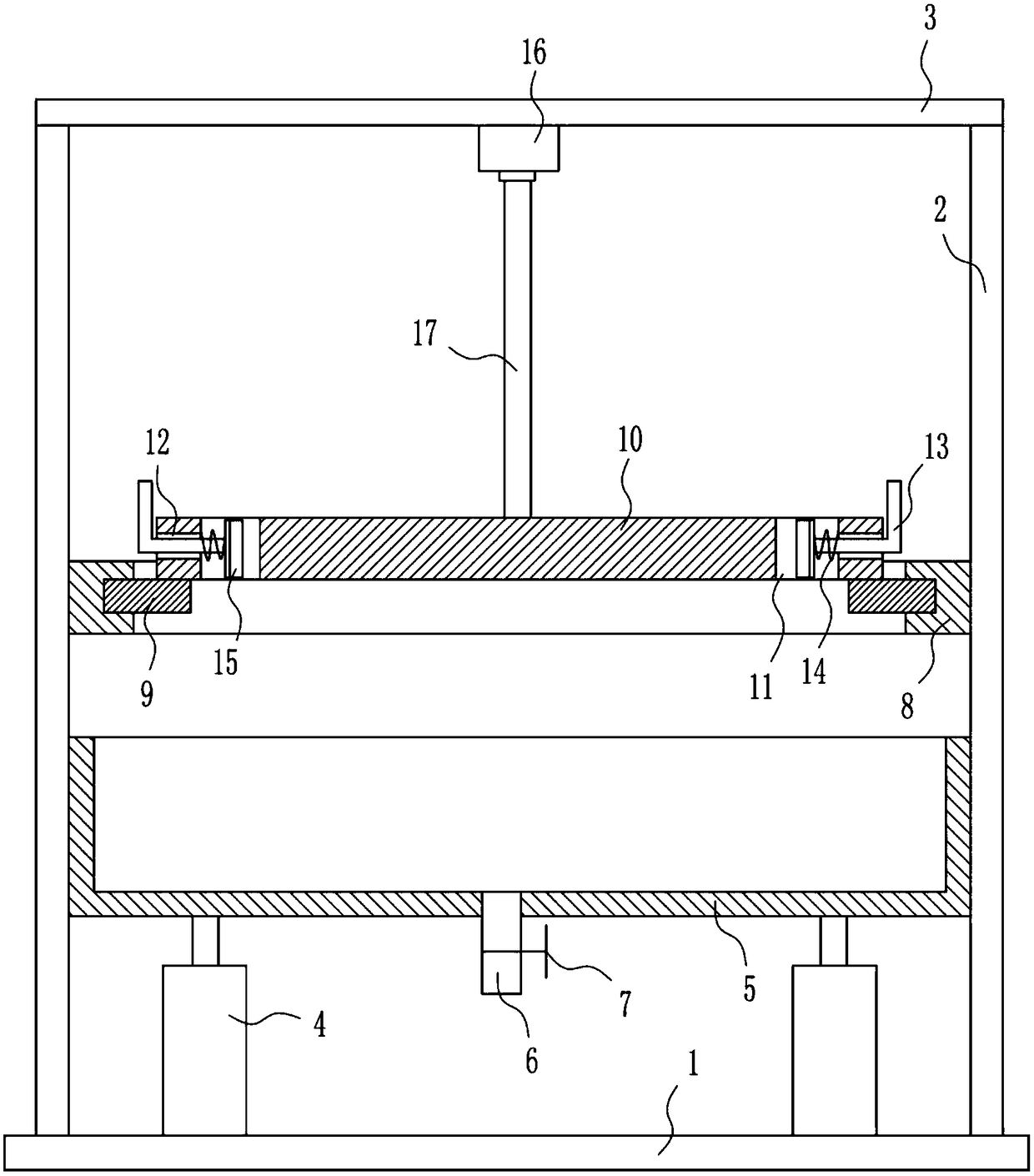

Embodiment 1

[0021] A brush cleaning machine, such as Figure 1-3 As shown, it includes a bottom plate 1, a vertical plate 2, a top plate 3, a cylinder 4, a frame body 5, a drain pipe 6, a first valve 7, an annular slide rail 8, an annular slider 9, a disc 10, an L-shaped tie rod 13, Spring 14, curved splint 15, motor 16 and rotating shaft 17, bottom plate 1 top, left and right sides are symmetrically equipped with cylinder 4, and cylinder 4 is vertically arranged, and frame body 5 is installed between the telescoping rods of left and right sides cylinder 4 , the middle of the bottom of the frame body 5 is connected with a drain pipe 6, the drain pipe 6 communicates with the inside of the frame body 5, the drain pipe 6 is provided with a first valve 7, and the left and right sides of the top of the bottom plate 1 are symmetrically installed with vertical boards 2 and vertical boards 2. Located on the left and right sides of the cylinder 4, a top plate 3 is installed between the tops of the...

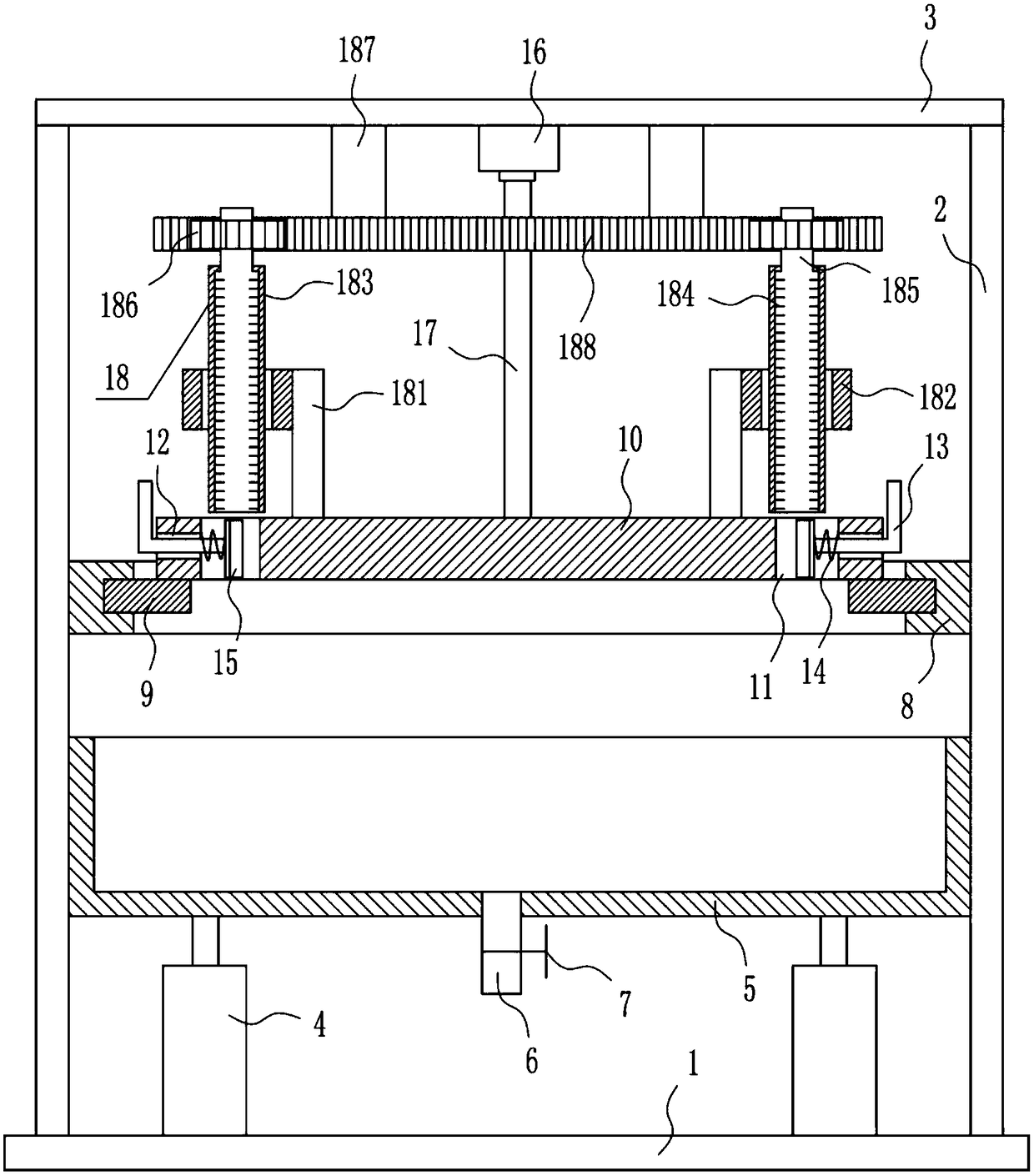

Embodiment 2

[0023] A brush cleaning machine, such as Figure 1-3 As shown, it includes a bottom plate 1, a vertical plate 2, a top plate 3, a cylinder 4, a frame body 5, a drain pipe 6, a first valve 7, an annular slide rail 8, an annular slider 9, a disc 10, an L-shaped tie rod 13, Spring 14, curved splint 15, motor 16 and rotating shaft 17, bottom plate 1 top, left and right sides are symmetrically equipped with cylinder 4, and cylinder 4 is vertically arranged, and frame body 5 is installed between the telescoping rods of left and right sides cylinder 4 , the middle of the bottom of the frame body 5 is connected with a drain pipe 6, the drain pipe 6 communicates with the inside of the frame body 5, the drain pipe 6 is provided with a first valve 7, and the left and right sides of the top of the bottom plate 1 are symmetrically installed with vertical boards 2 and vertical boards 2. Located on the left and right sides of the cylinder 4, a top plate 3 is installed between the tops of the...

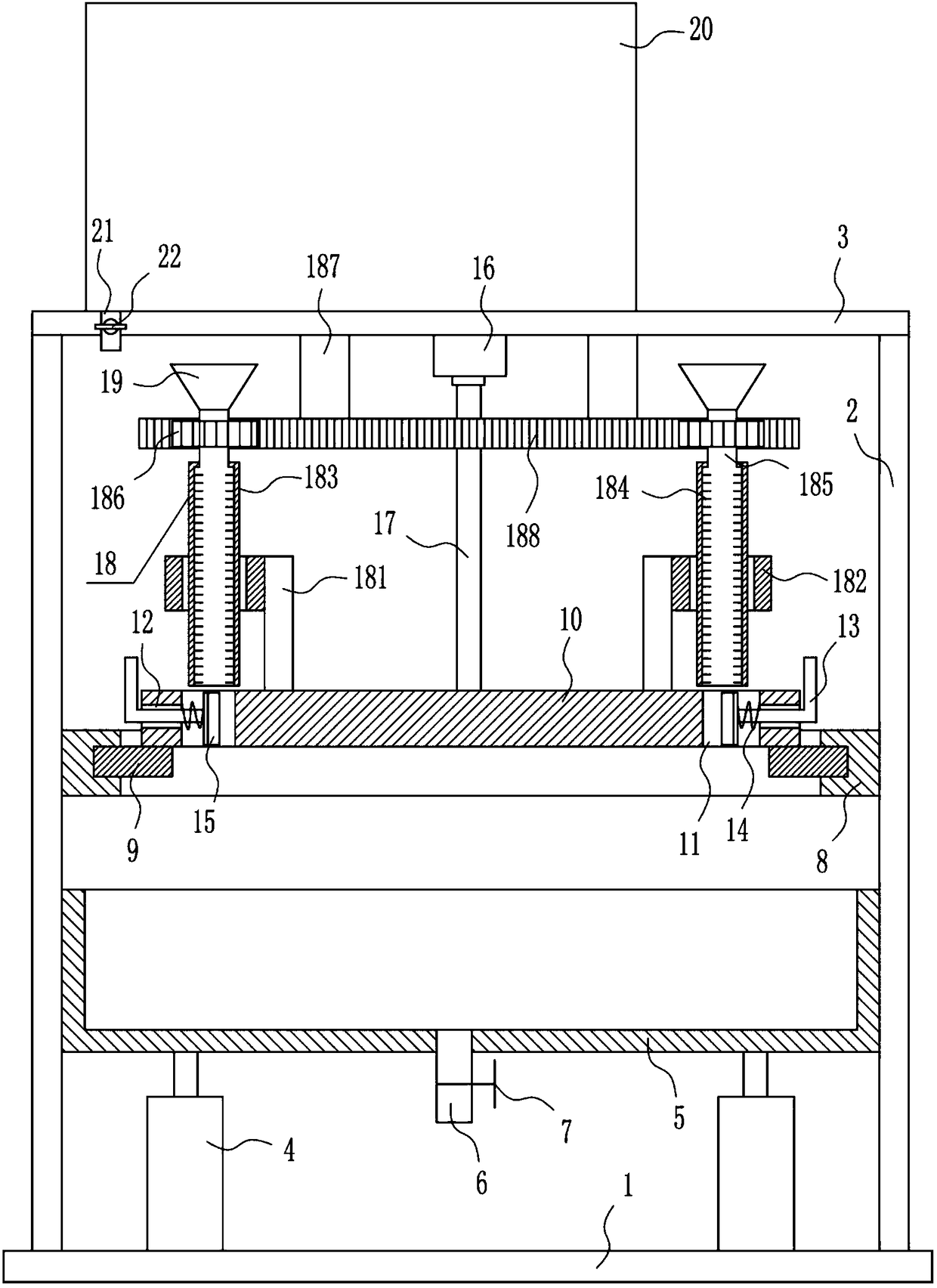

Embodiment 3

[0026] A brush cleaning machine, such as Figure 1-3 As shown, it includes a bottom plate 1, a vertical plate 2, a top plate 3, a cylinder 4, a frame body 5, a drain pipe 6, a first valve 7, an annular slide rail 8, an annular slider 9, a disc 10, an L-shaped tie rod 13, Spring 14, curved splint 15, motor 16 and rotating shaft 17, bottom plate 1 top, left and right sides are symmetrically equipped with cylinder 4, and cylinder 4 is vertically arranged, and frame body 5 is installed between the telescoping rods of left and right sides cylinder 4 , the middle of the bottom of the frame body 5 is connected with a drain pipe 6, the drain pipe 6 communicates with the inside of the frame body 5, the drain pipe 6 is provided with a first valve 7, and the left and right sides of the top of the bottom plate 1 are symmetrically installed with vertical boards 2 and vertical boards 2. Located on the left and right sides of the cylinder 4, a top plate 3 is installed between the tops of the v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com