A kind of bark peeling equipment for papermaking

A kind of equipment and technology of bark, applied in the field of peeling equipment, can solve the problems of incomplete peeling, time-consuming and laborious, inconvenient collection of bark, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

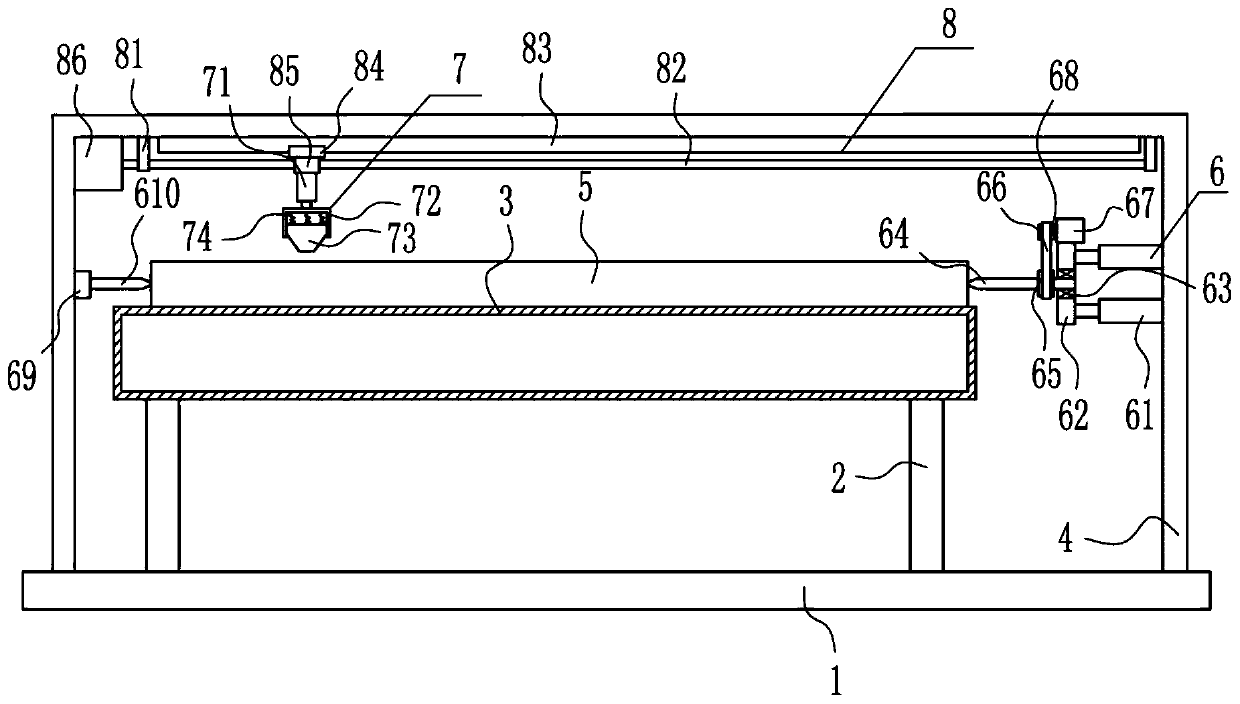

[0031] A kind of bark peeling equipment for papermaking, such as Figure 1-5 As shown, it includes a base plate 1, a support rod 2, a box body 3, a frame 4, a rotating device 6, a peeling device 7 and a cutting device 9, and the left and right sides of the top of the base plate 1 are equipped with a support rod 2, and the left and right sides of the support rods 2 A box body 3 is installed between the tops, a frame 4 is installed on the top of the bottom plate 1, the box body 3 is located in the frame 4, and a rotating device 6 is installed between the upper left surface and the upper right surface of the frame 4, and the rotating device 6 is located in the Above the casing 3, a moving device 8 is arranged on the inner top of the frame 4, and a peeling device 7 is arranged on the moving part of the moving device 8, and the peeling device 7 is located above the casing 3.

Embodiment 2

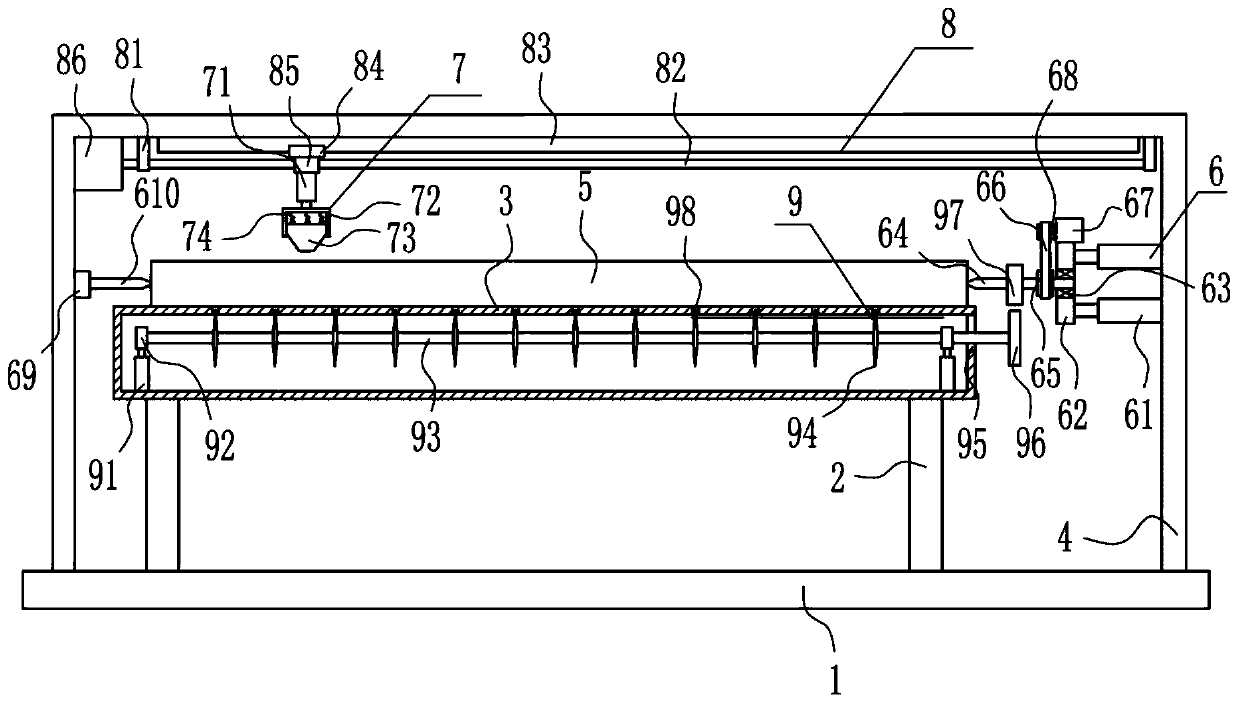

[0033] A kind of bark peeling equipment for papermaking, such as Figure 1-5 As shown, it includes a base plate 1, a support rod 2, a box body 3, a frame 4, a rotating device 6, a peeling device 7 and a cutting device 9, and the left and right sides of the top of the base plate 1 are equipped with a support rod 2, and the left and right sides of the support rods 2 A box body 3 is installed between the tops, a frame 4 is installed on the top of the bottom plate 1, the box body 3 is located in the frame 4, and a rotating device 6 is installed between the upper left surface and the upper right surface of the frame 4, and the rotating device 6 is located in the Above the casing 3, a moving device 8 is arranged on the inner top of the frame 4, and a peeling device 7 is arranged on the moving part of the moving device 8, and the peeling device 7 is located above the casing 3.

[0034] Rotary device 6 comprises first cylinder 61, riser 62, first bearing block 63, first thimble 64, fi...

Embodiment 3

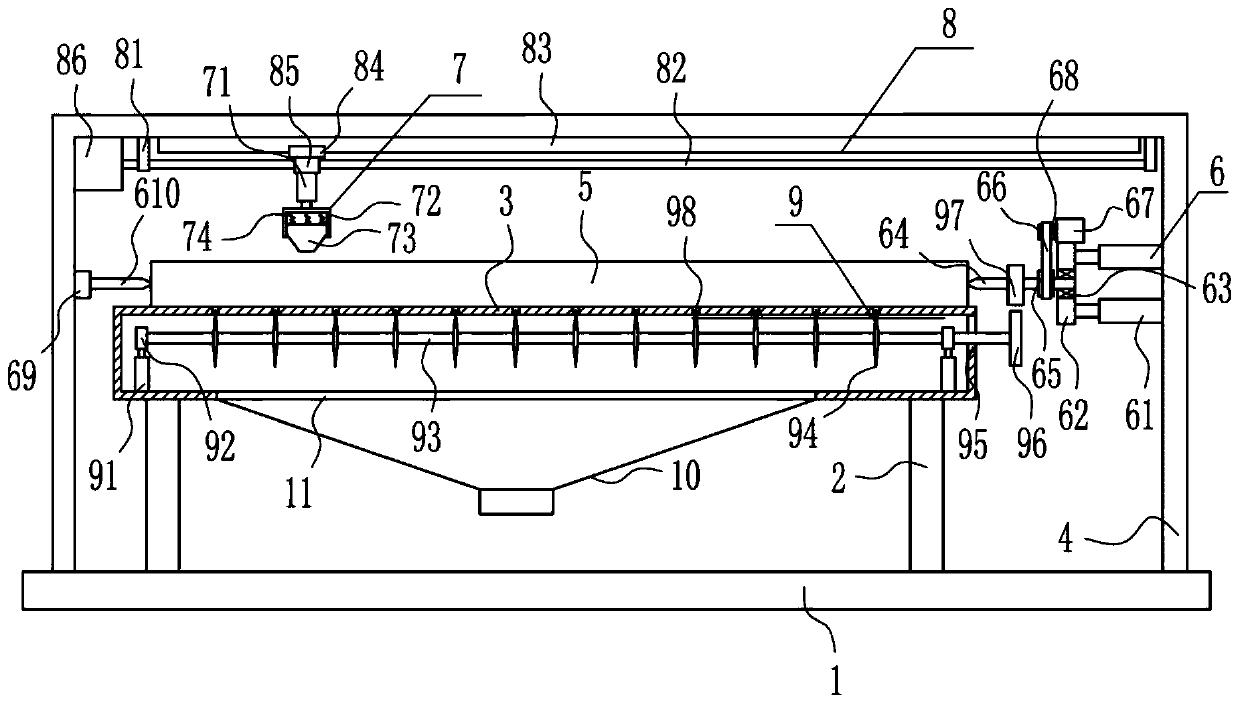

[0036] A kind of bark peeling equipment for papermaking, such as Figure 1-5 As shown, it includes a base plate 1, a support rod 2, a box body 3, a frame 4, a rotating device 6, a peeling device 7 and a cutting device 9, and the left and right sides of the top of the base plate 1 are equipped with a support rod 2, and the left and right sides of the support rods 2 A box body 3 is installed between the tops, a frame 4 is installed on the top of the bottom plate 1, the box body 3 is located in the frame 4, and a rotating device 6 is installed between the upper left surface and the upper right surface of the frame 4, and the rotating device 6 is located in the Above the casing 3, a moving device 8 is arranged on the inner top of the frame 4, and a peeling device 7 is arranged on the moving part of the moving device 8, and the peeling device 7 is located above the casing 3.

[0037] Rotary device 6 comprises first cylinder 61, riser 62, first bearing block 63, first thimble 64, fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com