Self-aligning device for storage rack production

An automatic centering and shelf technology, applied in positioning devices, clamping devices, clamping, etc., can solve the problems of cylindrical steel materials that are difficult to adapt to different sizes, complex fixture structures, and affect production efficiency, so as to ensure processing and production Quality, improved production efficiency, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

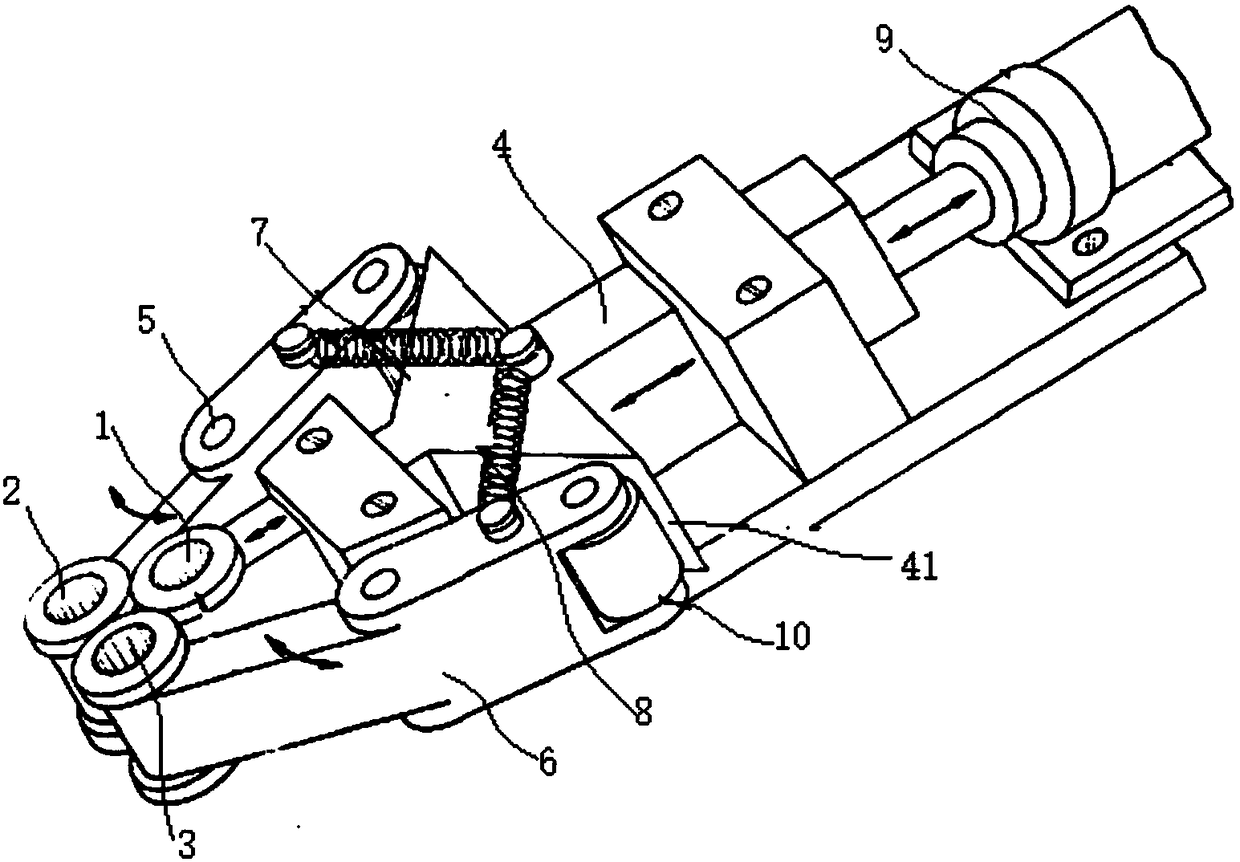

[0014] refer to figure 1 As shown, it is a schematic structural diagram of the automatic centering device for the production of storage shelves provided in this embodiment. The clamp includes a first clamping claw 1, a second clamping claw 2, a third clamping claw 3, a first clamping Push plate 4 , second clamping plate 5 , third clamping plate 6 , first spring 7 , second spring 8 and pusher 9 .

[0015] Wherein, the first clamping claw 1 is installed in the beginning of the first clamping push plate 4, the end of the first clamping push plate 4 is connected with the pusher 9, and the first clamping push plate 4 is driven by the pusher 9 Move back and forth; the second clamping claw 2 and the third clamping claw 3 are respectively installed in the starting ends of the second clamping plate 5 and the third clamping plate 6, at the end of the second clam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com