Welding fixing device for automobile pipe

A technology for pipe fitting welding and fixing device, which is applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of pipe fittings such as difficulty in centering, and achieve the effect of solving the difficulty in centering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following is further described in detail through specific implementation methods:

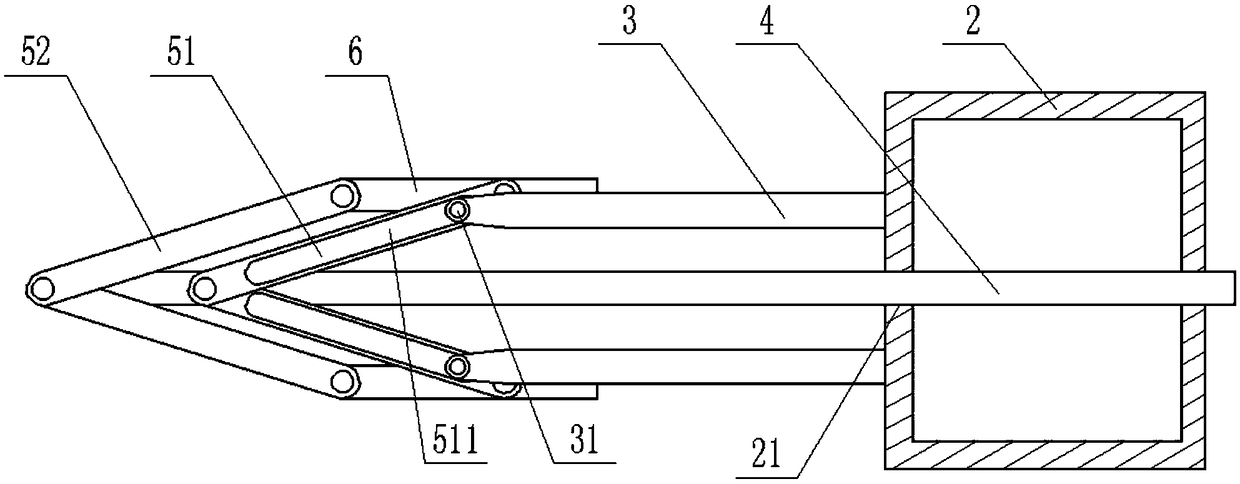

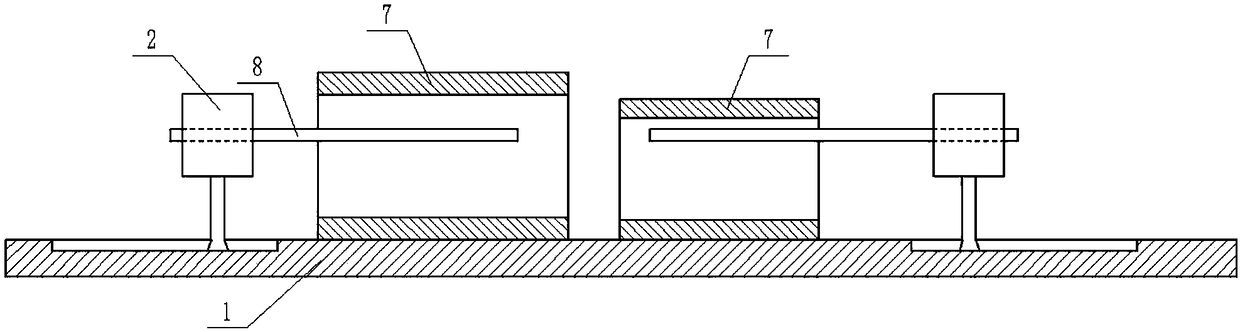

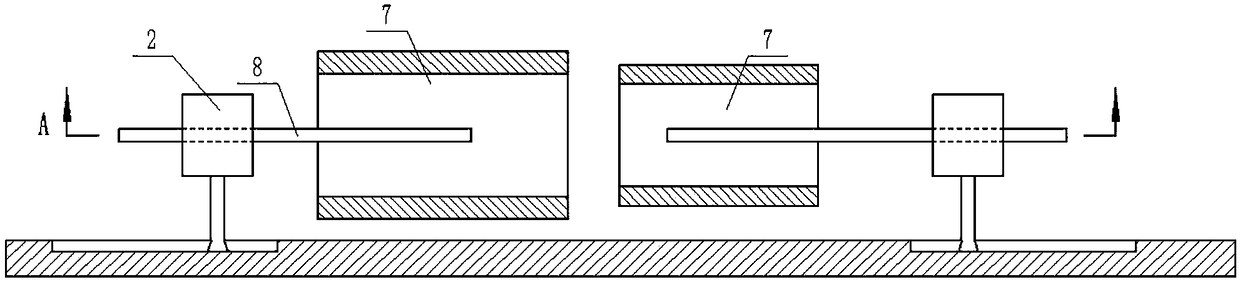

[0030] The reference signs in the drawings of the description include: processing table 1, box body 2, conveyor belt 11, sliding hole 21, positioning rod 3, pull rod 4, first connecting rod 51, second connecting rod 52, strut 6, chute 511, rotating shaft 31, pipe fitting 7, fixing mechanism 8.

[0031] The embodiment is basically as figure 1 with Figure 4 As shown: the welding and fixing device for automobile pipe fittings, including a processing table 1, a box body 2 is arranged symmetrically on both sides of the processing table 1, and the box body 2 is slidably connected to the surface of the processing table 1, and there are two Parallel conveyor belts 11, two conveyor belts 11 are located between the two casings 2; the casing 2 is provided with a slide hole 21, and the side of the casing 2 facing the conveyor belt 11 is provided with a fixing mechanism 8, and the fixing mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com