Airtight powder screening system and method for metal 3D printer

A 3D printer, metal powder technology, applied in chemical instruments and methods, sieves, solid separation, etc., can solve the problems of reducing product quality, printing parts quality, sieving material pollution, etc., to improve system stability, improve The speed of sieving powder, the effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

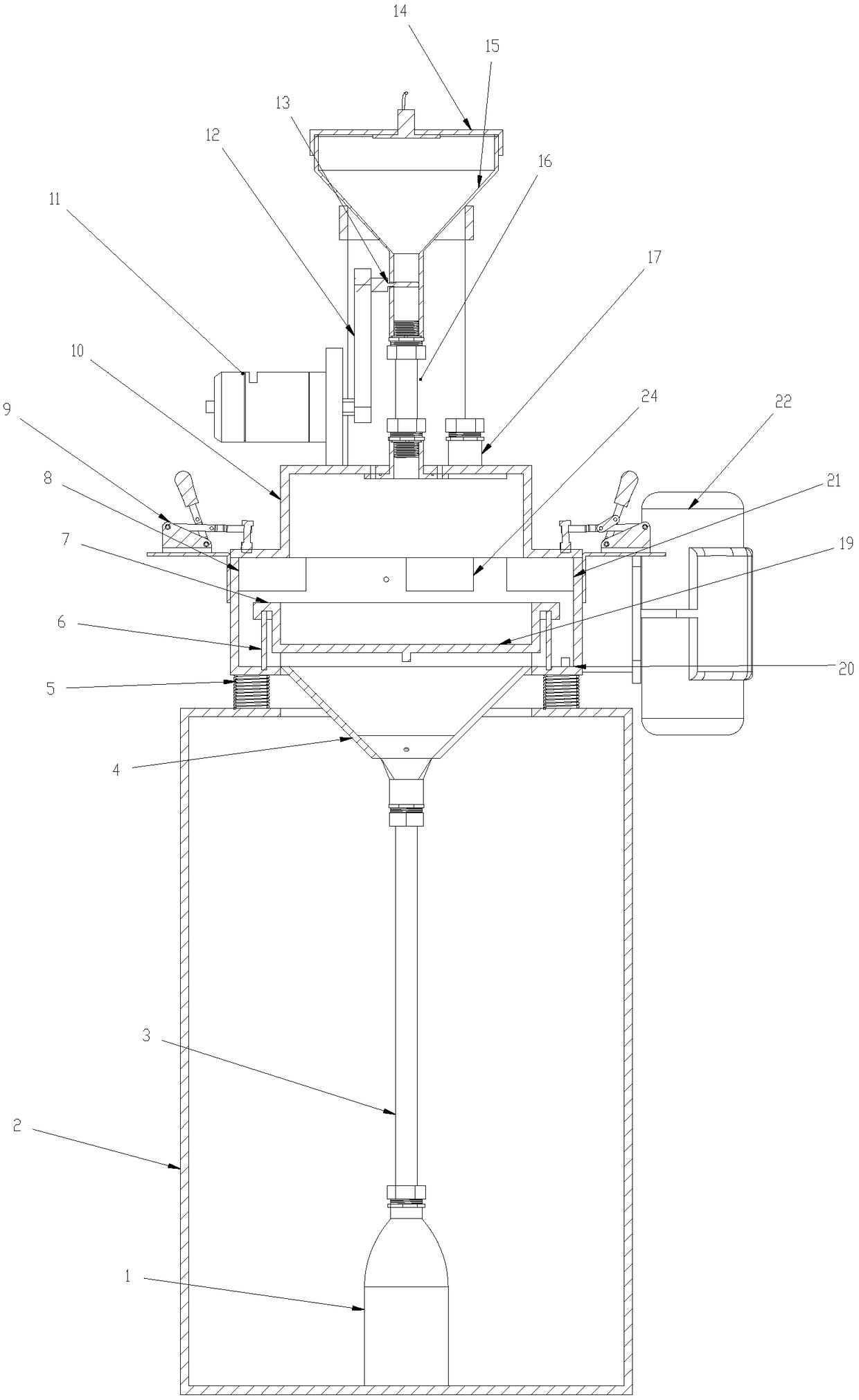

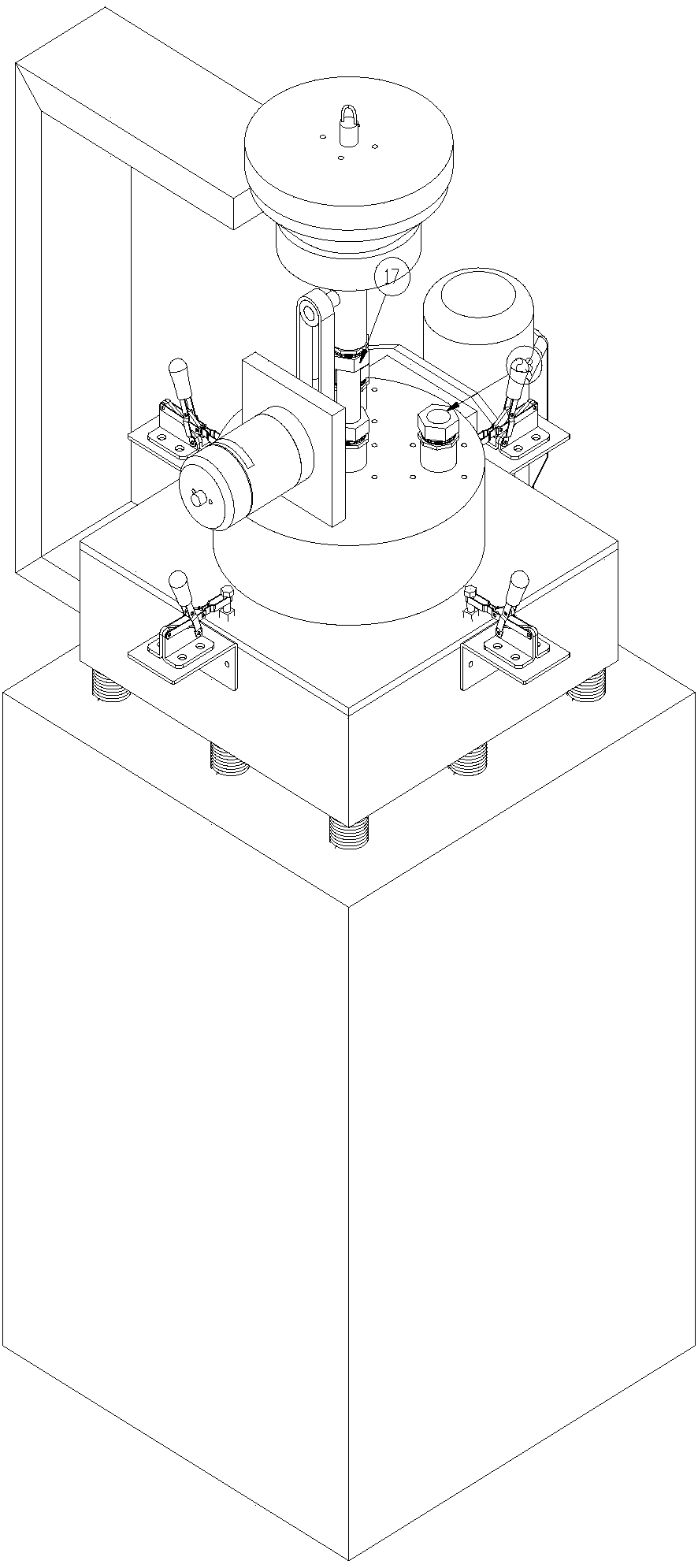

[0048] Such as Figure 1-3 shown. The invention discloses an airtight powder screening system applied to a metal 3D printer, which includes a feeding mechanism, a vibrating powder screening mechanism, a powder collecting mechanism and a control module 8 arranged in sequence from top to bottom; the feeding mechanism is used for The metal powder is delivered to the vibrating sieving mechanism; the vibrating sieving mechanism is used for vibrating and screening the metal powder; the powder collection mechanism is used for collecting and storing the vibrating and screening metal powder;

[0049] The connection between the feeding mechanism, the vibrating powder sieving mechanism and the powder collecting mechanism is an airtight connection, so that the metal powder feeding, vibrating powder sieving and collection and storage processes are all carried out under a sealed path isolated from the atmosphere;

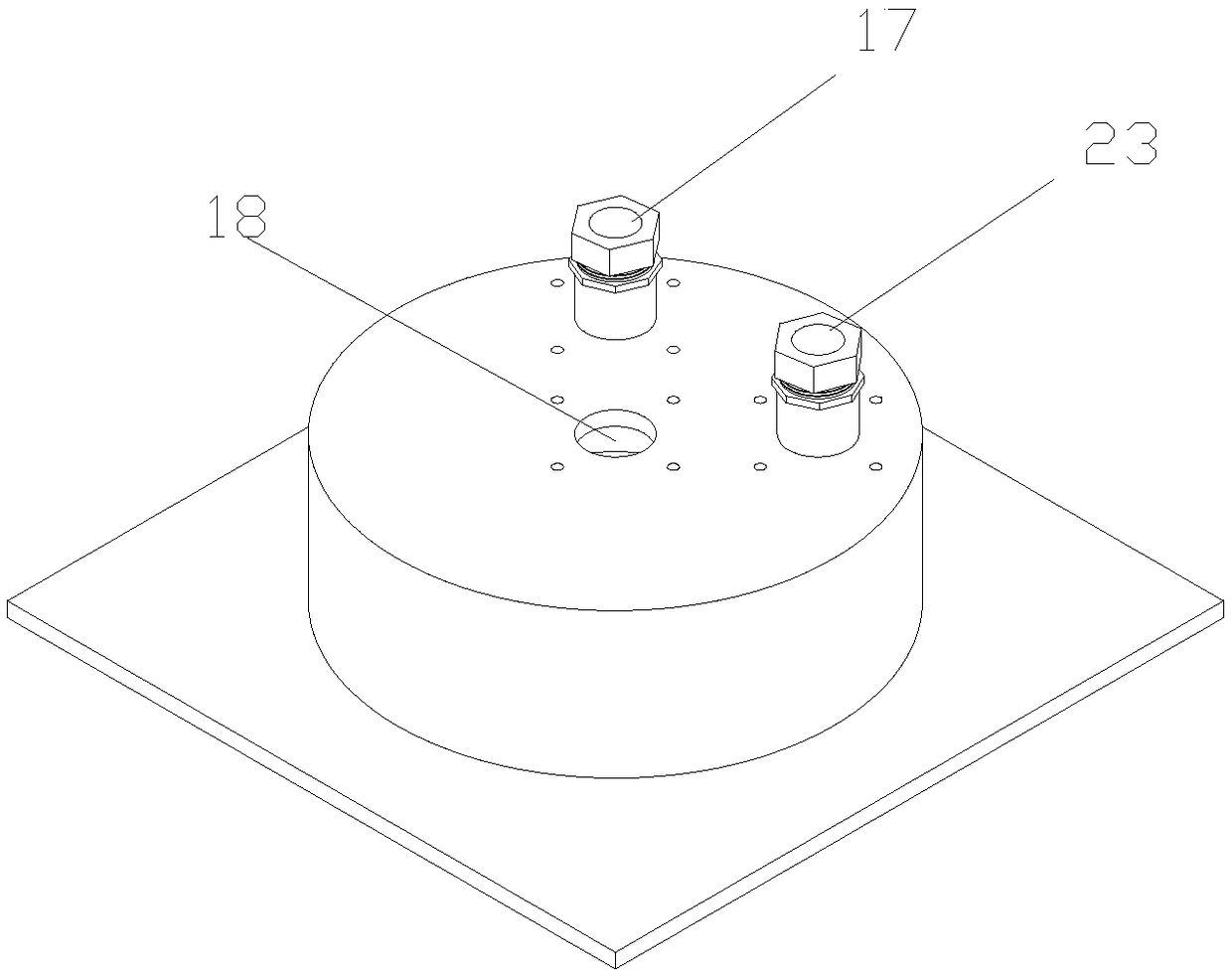

[0050] Described vibratory powder sieve mechanism comprises: section is fun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com