Limiting structure for limiting displacement of mould floating template

A floating template and limit structure technology, applied in manufacturing tools, forming tools, metal processing equipment, etc., can solve the problems of reducing the rigidity and deflection of the L-shaped limit block, increasing the thread diameter, reducing the safety factor, etc. Simple structure, improved limit accuracy and low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to further understand the invention content, characteristics and effects of the present invention, the following embodiments are enumerated hereby, and detailed descriptions are as follows in conjunction with the accompanying drawings:

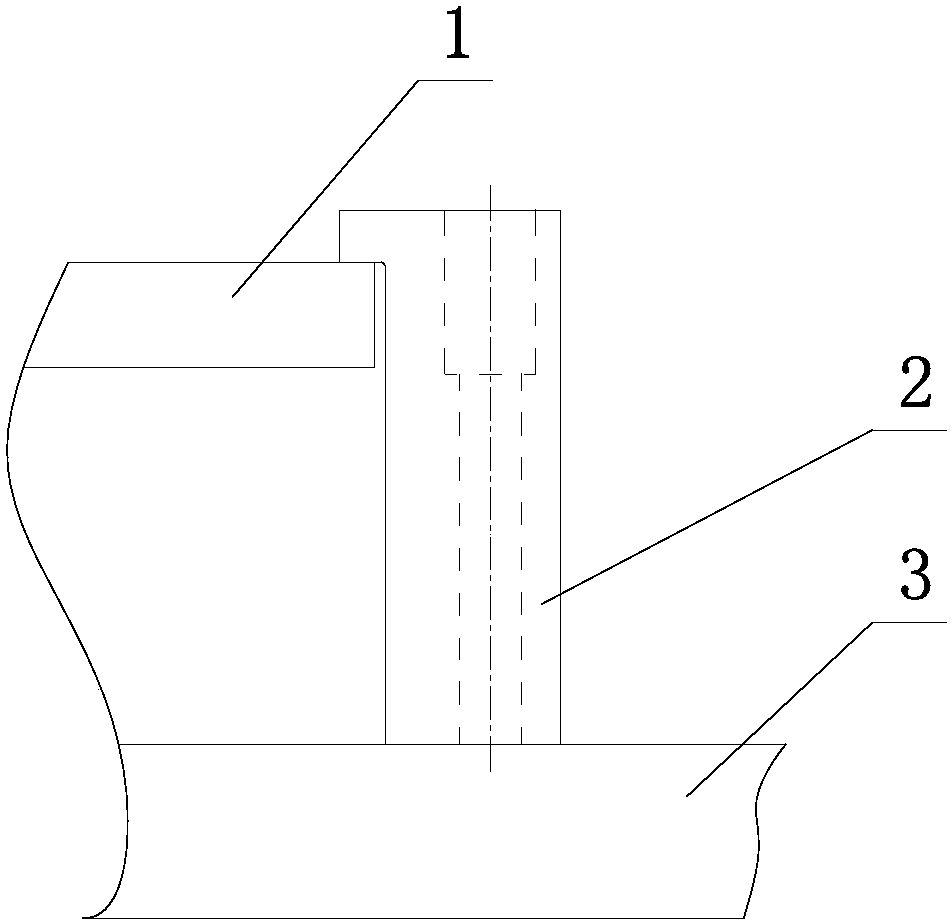

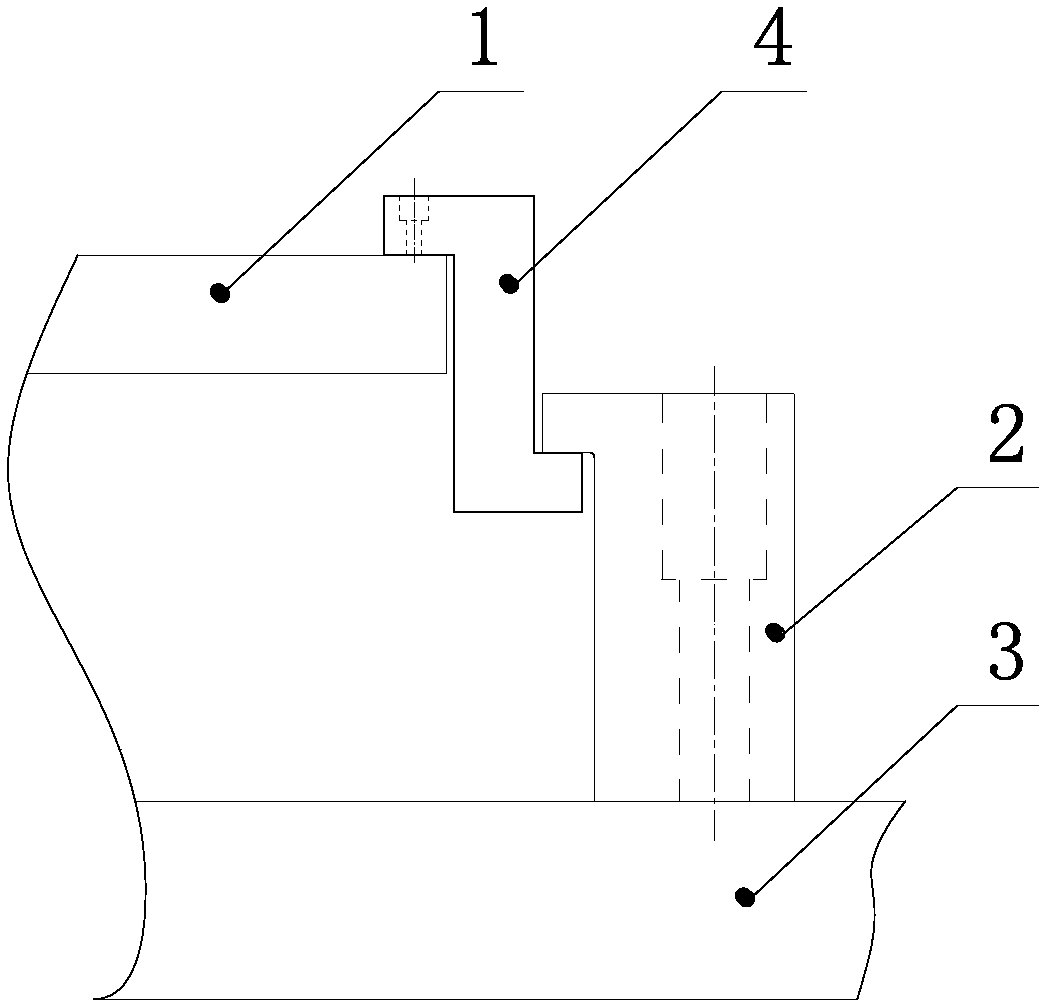

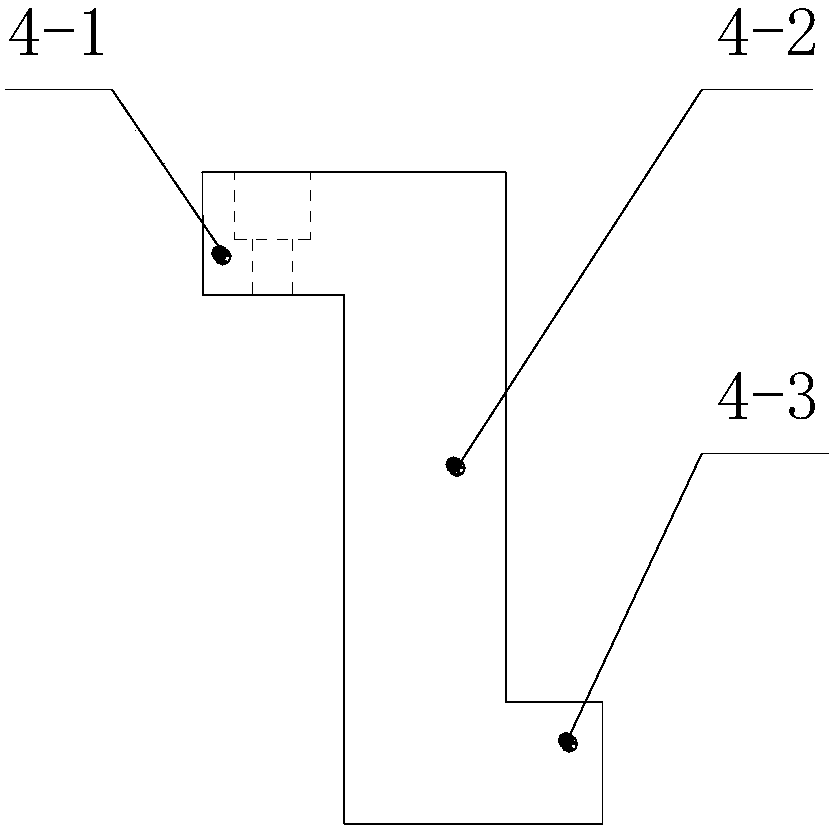

[0020] See Figure 1 to Figure 6 , a limiting structure for limiting the displacement of the floating template of the mold, including a floating template 1 and an L-shaped limiting block 2, and the L-shaped limiting block 2 includes a horizontal part A2-1 and a vertical part A2-2 perpendicular to each other, so The vertical part A2-2 of the L-shaped limiting block is fixedly connected to the fixed plate 3 or the mold base of the mold, and the horizontal part A2-1 of the L-shaped limiting block is matched with the floating template 1 to limit the The vertical displacement of the floating formwork 1 to one side, if the floating formwork 1 is an upper floating formwork, limit the downward vertical displacement of the floating form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com