Intermittent discharging type screening device for glitter powder for decoration

A screening device and glitter powder technology, which is applied in the direction of filter, solid separation, grid, etc., can solve the problems of insufficient screening of glitter powder, low screening efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

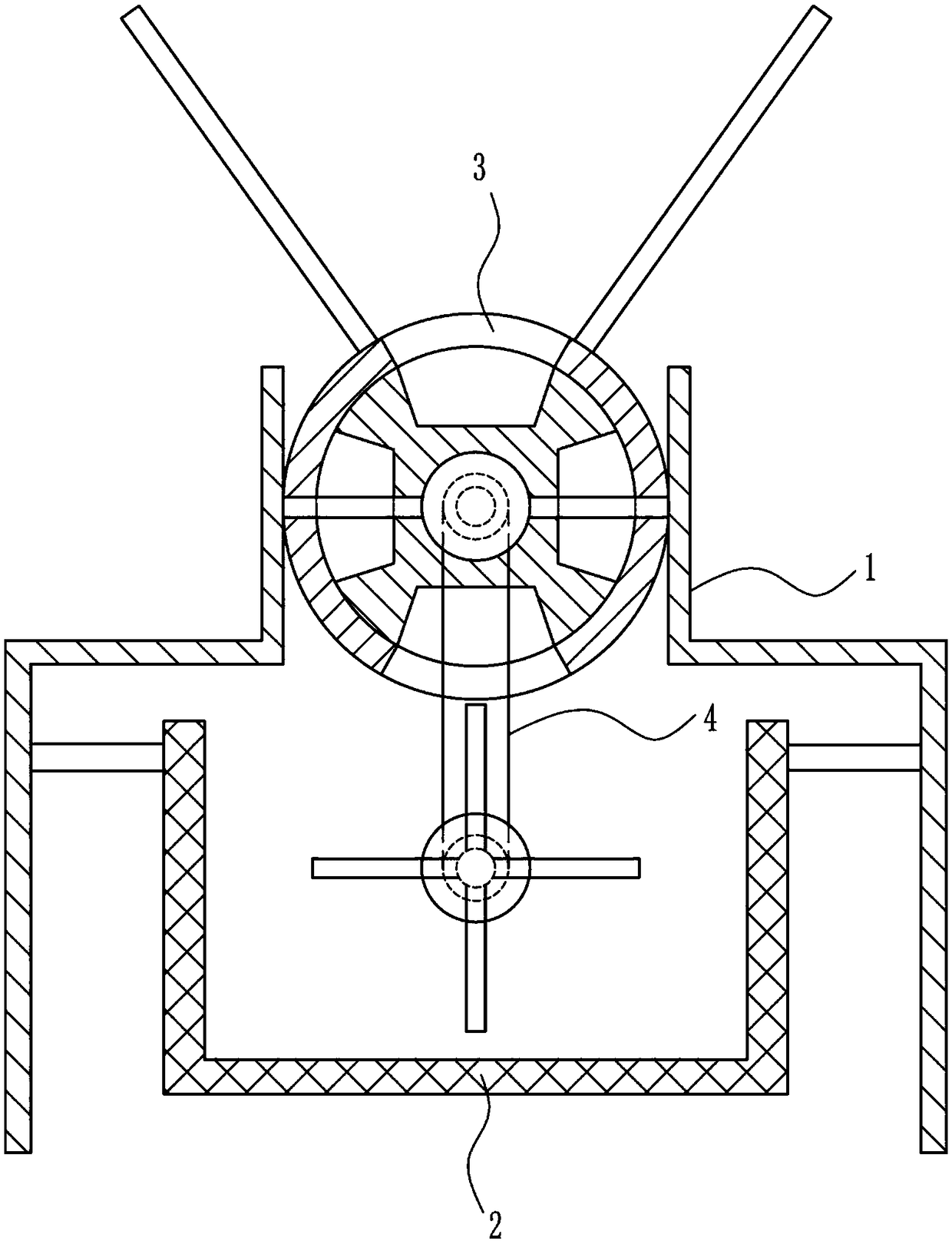

[0036] A decorative glitter powder intermittent discharge screening device, such as Figure 1-7 As shown, it includes a placing rack 1, a screen frame 2, a feeding mechanism 3 and a screening mechanism 4, the lower part of the placing rack 1 is connected with a screen frame 2, the upper part of the placing rack 1 is connected with a feeding mechanism 3, and the feeding mechanism 3 and the screen frame 2 are connected with a screening mechanism 4 , and the screening mechanism 4 is located below the feeding mechanism 3 .

Embodiment 2

[0038] A decorative glitter powder intermittent discharge screening device, such as Figure 1-7 As shown, it includes a placing rack 1, a screen frame 2, a feeding mechanism 3 and a screening mechanism 4, the lower part of the placing rack 1 is connected with a screen frame 2, the upper part of the placing rack 1 is connected with a feeding mechanism 3, and the feeding mechanism 3 and the screen frame 2 are connected with a screening mechanism 4 , and the screening mechanism 4 is located below the feeding mechanism 3 .

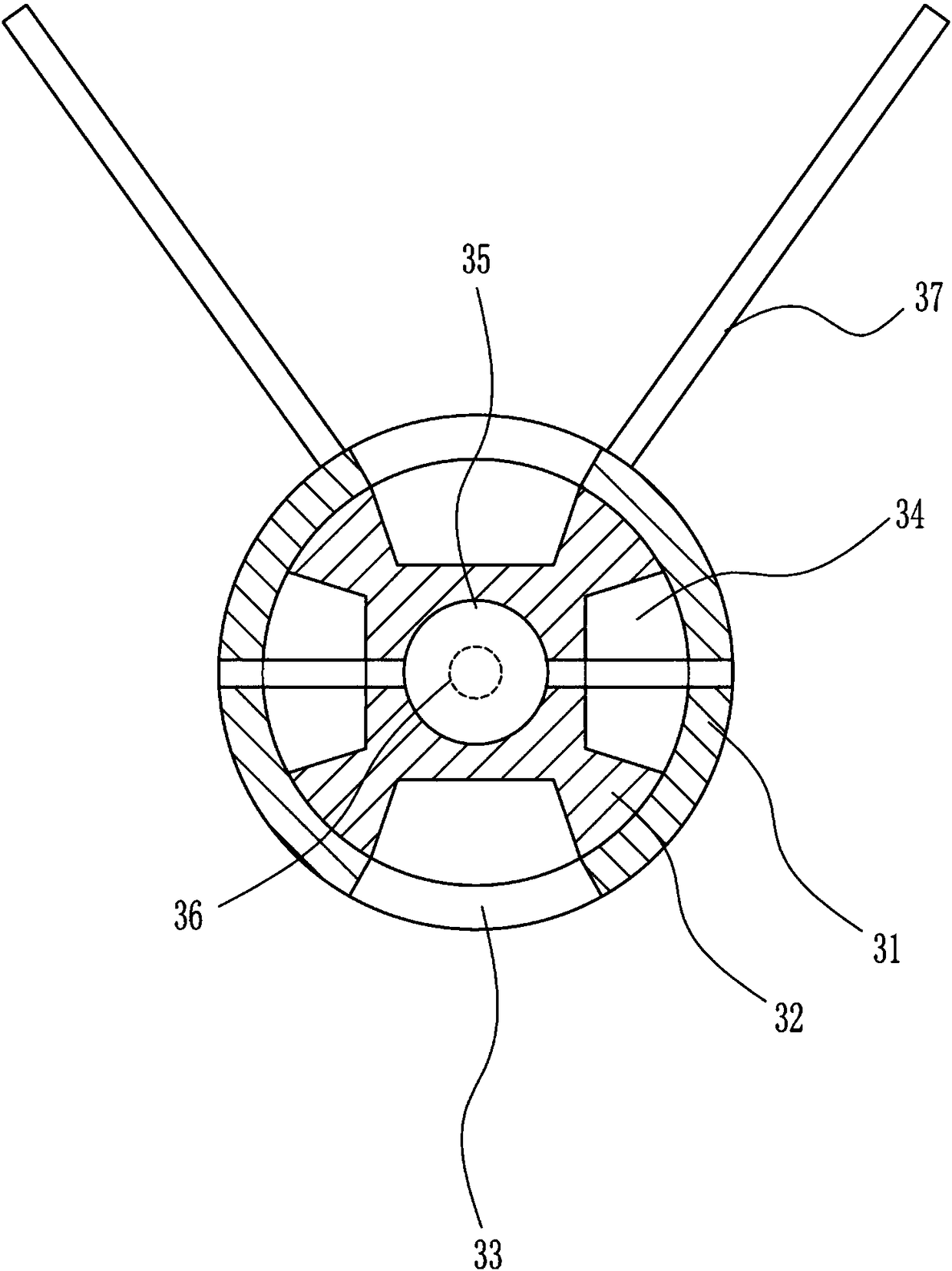

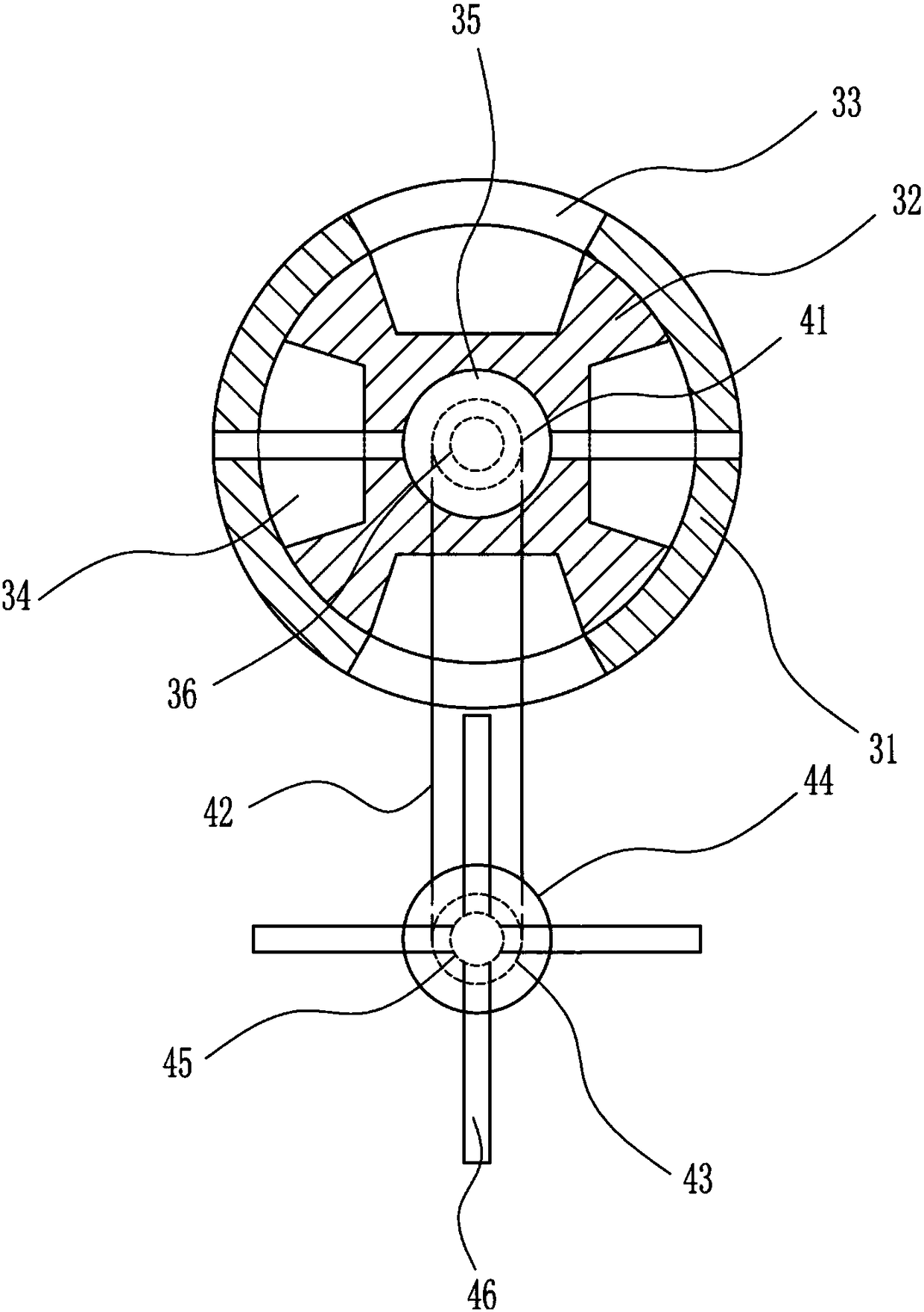

[0039] The feeding mechanism 3 includes a fixed cylinder 31, a rotating cylinder 32, a motor 35, a rotating shaft 36 and a feeding hopper 37. A fixed cylinder 31 is connected between the upper parts of the placement racks 1 on the left and right sides, and the upper and lower sides of the fixed cylinder 31 are symmetrical. There is a first through hole 33 in the upper part of the fixed cylinder 31, and a feeding hopper 37 is connected to the upper part of the ...

Embodiment 3

[0041] A decorative glitter powder intermittent discharge screening device, such as Figure 1-7 As shown, it includes a placing rack 1, a screen frame 2, a feeding mechanism 3 and a screening mechanism 4, the lower part of the placing rack 1 is connected with a screen frame 2, the upper part of the placing rack 1 is connected with a feeding mechanism 3, and the feeding mechanism 3 and the screen frame 2 are connected with a screening mechanism 4 , and the screening mechanism 4 is located below the feeding mechanism 3 .

[0042] The feeding mechanism 3 includes a fixed cylinder 31, a rotating cylinder 32, a motor 35, a rotating shaft 36 and a feeding hopper 37. A fixed cylinder 31 is connected between the upper parts of the placement racks 1 on the left and right sides, and the upper and lower sides of the fixed cylinder 31 are symmetrical. There is a first through hole 33 in the upper part of the fixed cylinder 31, and a feeding hopper 37 is connected to the upper part of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com