Device and technology for desulfurizing and removing white smoke

A white smoke and process technology, which is applied in the desulfurization and white smoke removal device and process field, can solve the problem of no improvement in desulfurization efficiency, achieve the effects of reducing moisture content, reducing smoke temperature, and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

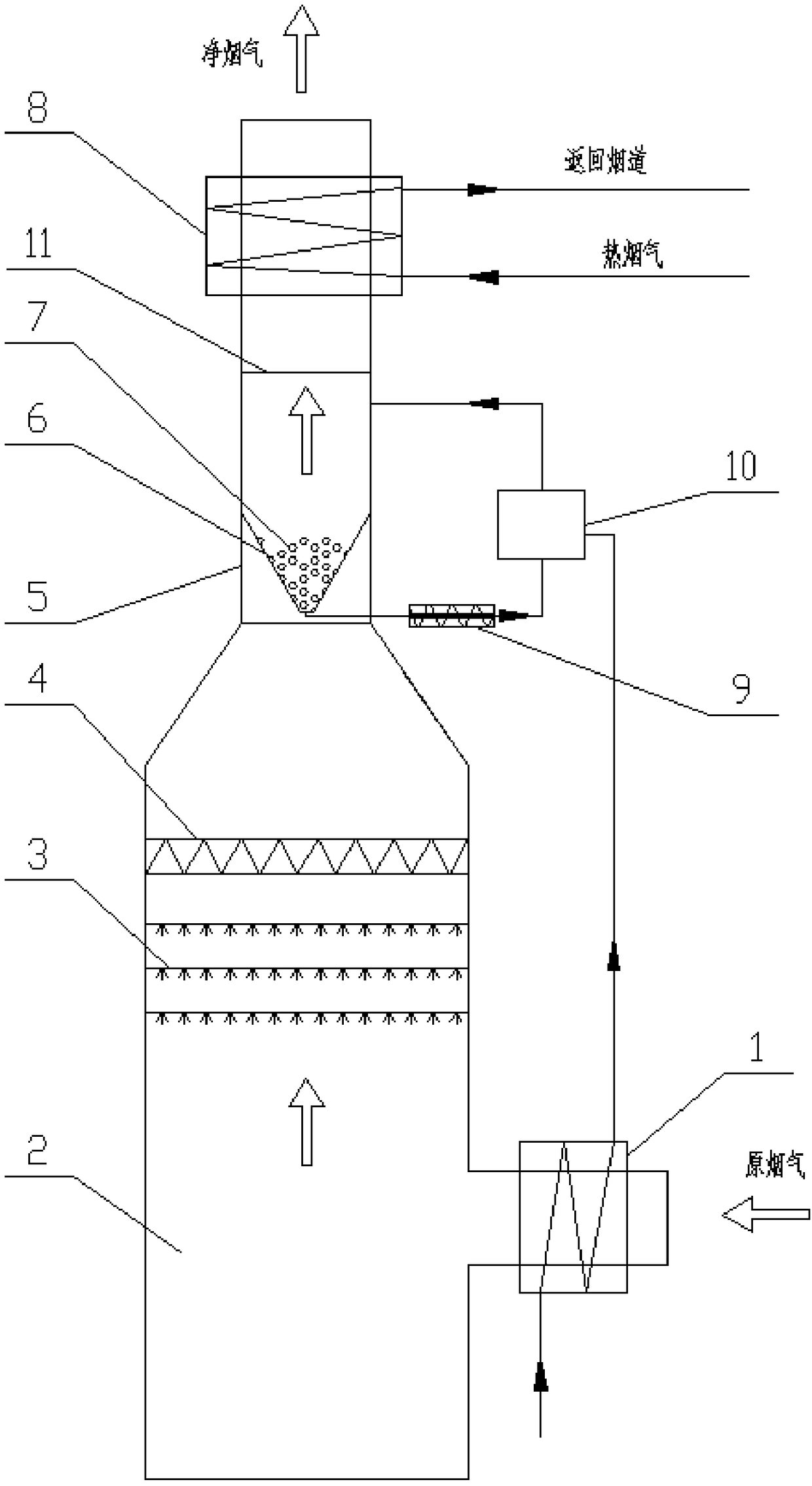

[0026] see figure 1 , a device for desulfurization and white smoke removal, comprising an inlet heat exchanger 1, a reaction tower 2, a spray layer 3, a mist eliminator 4, a chimney 5, an orifice plate 6, polymer water-absorbing particles 7, a chimney heat exchanger 8, Conveyor 9, drier 10, orifice plate 2 11; Described reaction tower 2 is provided with chimney 5, and reaction tower 2 is provided with spray layer 3 and demister 4 from bottom to top, and in chimney 5, from bottom to top Orifice one 6 and orifice two 11 are arranged on the top, polymer water-absorbing particles 7 are placed on the orifice one 6, chimney heat exchanger 8 is arranged on the top of the chimney 5, and a conveyor passes through the bottom of the orifice one 6 9 is connected to one end of the drier 10, and the other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com