Oil-fried Udon noodles and processing method thereof

A processing method and udon noodle technology, which is applied in the field of fried udon noodles and its processing, can solve problems such as difficulty in reflecting stickiness, dark yellow color of the product, and poor quality of raw materials, so as to improve smoothness and softness The effect of less air residue, excellent gelatinization properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with specific examples, but the present invention is not limited to these examples.

[0033] The invention discloses a processing method of fried udon noodles. The fried udon noodles prepared by the processing method have soft, glutinous, smooth and tough taste, and white and bright color. Investigate its realization reason, mainly be that the present invention optimizes and innovates the processing method of this deep-fried udon noodles, and its raw material formula is carried out optimized combination, be specifically described as follows:

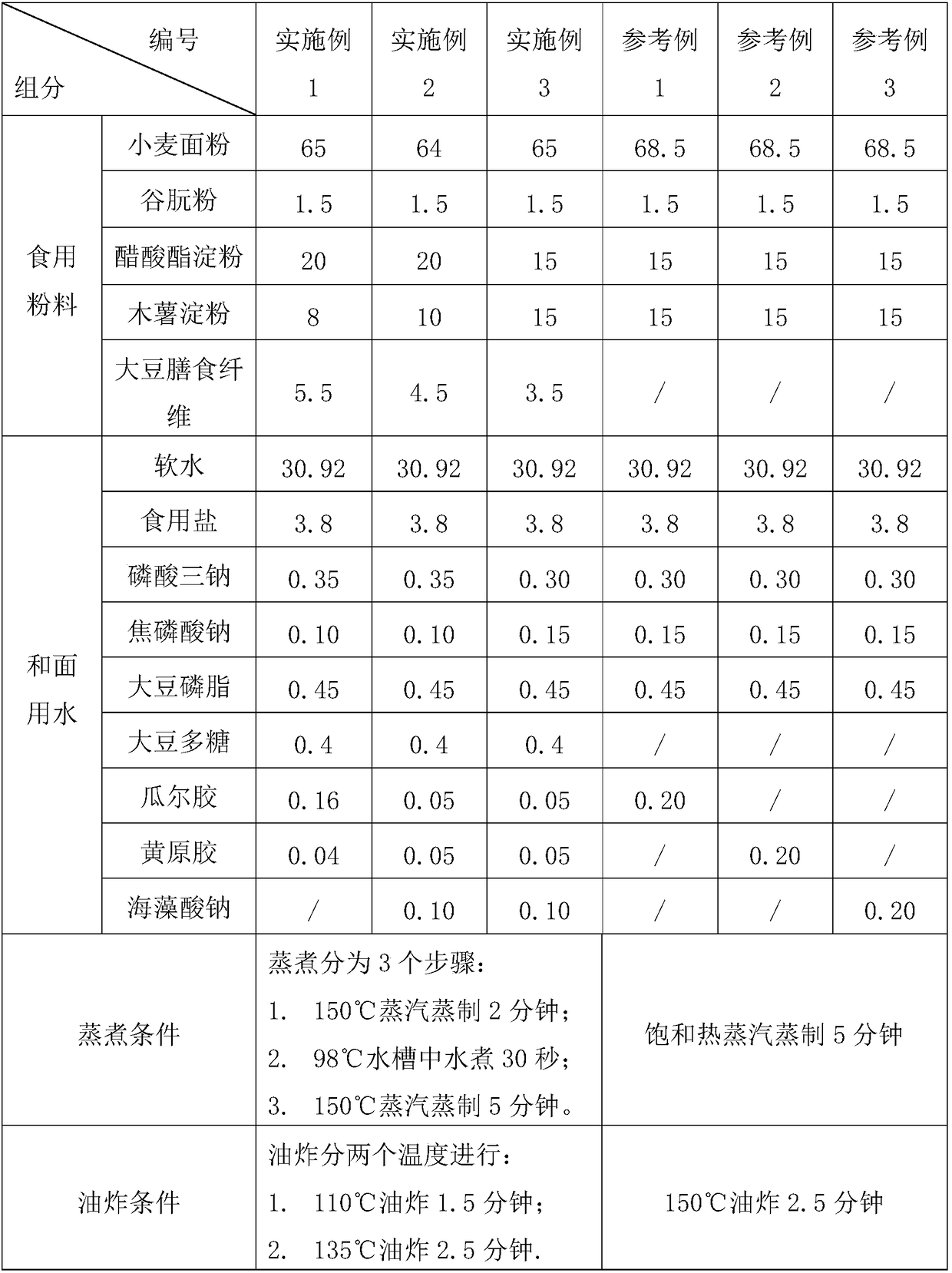

[0034] One, adopt processing method of the present invention to prepare fried udon noodles

[0035] Embodiments 1 to 3 and Reference Examples 1 to 3 were prepared according to the raw material formula and process parameters shown in Table 1, and according to the following steps 1 to 7:

[0036] Step 1, firstly dissolve an appropriate amount of edible s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Extensibility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com