Saline Layer Pressure Relief Methods

A brine layer and brine technology, which is applied in earthwork drilling, wellbore/well components, flushing wellbore, etc., can solve the problems of polluted drilling fluid, brine intrusion into the wellbore, and difficulty in predicting the brine layer accurately, so as to increase safety and improve Effect of Drilling Success Rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

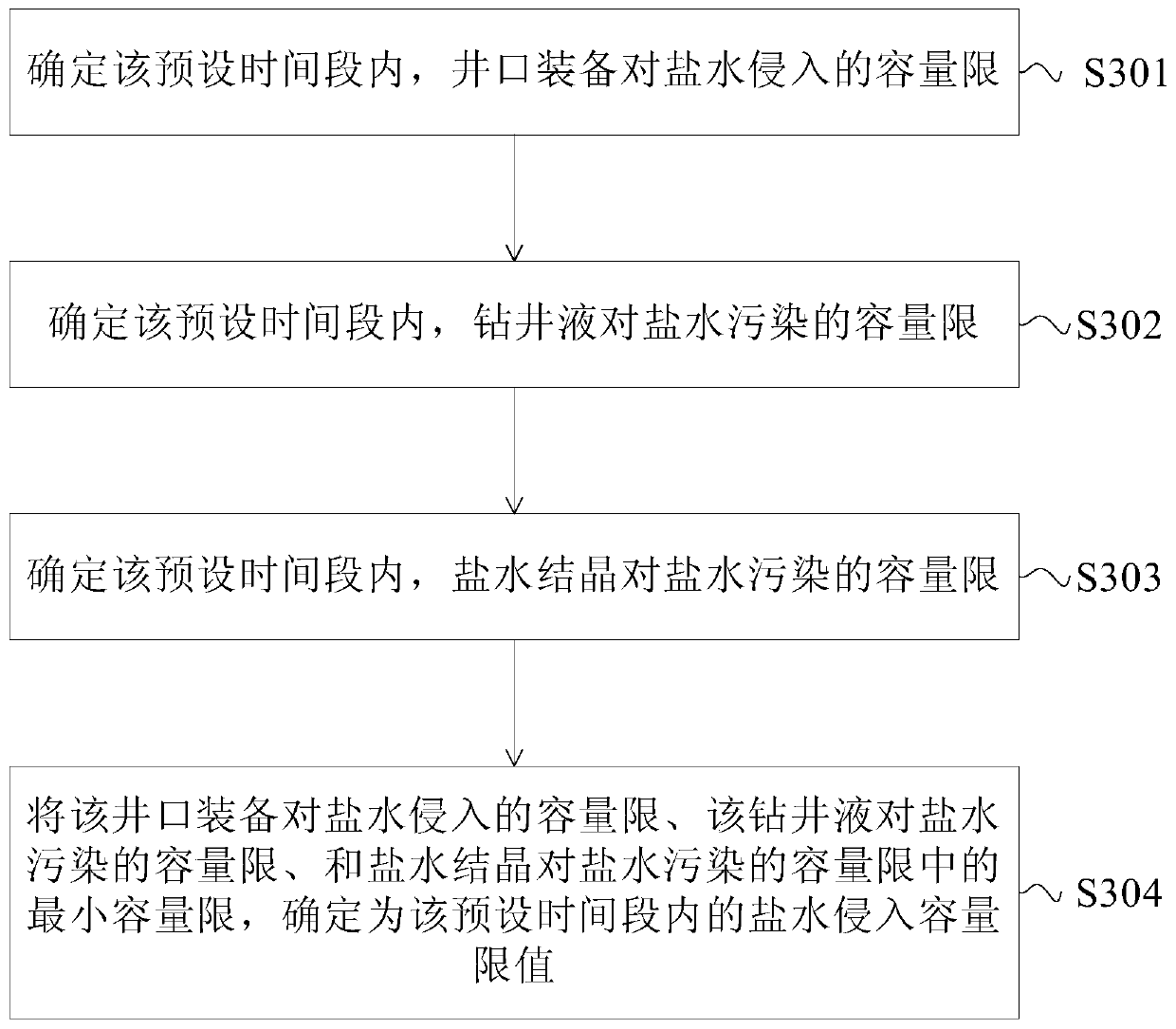

[0048] The invention provides a method for pressure relief of a salt water layer. figure 1 It is a flow chart of a method for releasing pressure from a saltwater layer provided by the present invention. Such as figure 1 As shown, the salt water layer pressure relief method may include:

[0049] S101. Shut down the well when the drilling fluid overflows, and determine the salt water intrusion capacity limit during the preset time period when the drilling fluid overflow starts.

[0050] During the drilling process, when drilling into a saltwater layer, the saltwater in the saltwater layer will flow into the wellbore, causing the drilling fluid to overflow. The pressure of the salt water layer may be greater than or equal to the preset pressure, and the salt water layer may also be referred to as a high pressure salt water layer.

[0051] In order to prevent the brine from the brine layer from continuing to enter the wellbore, causing pollution to the drilling fluid, as well as the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com