Table and chair board chamfering machining device

A technology for corner processing and board downturning, applied in the field of table and chair board chamfering processing equipment, can solve problems such as easy raising of wood chips, inability to separate and store table and chair board waste, affecting cleaning efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

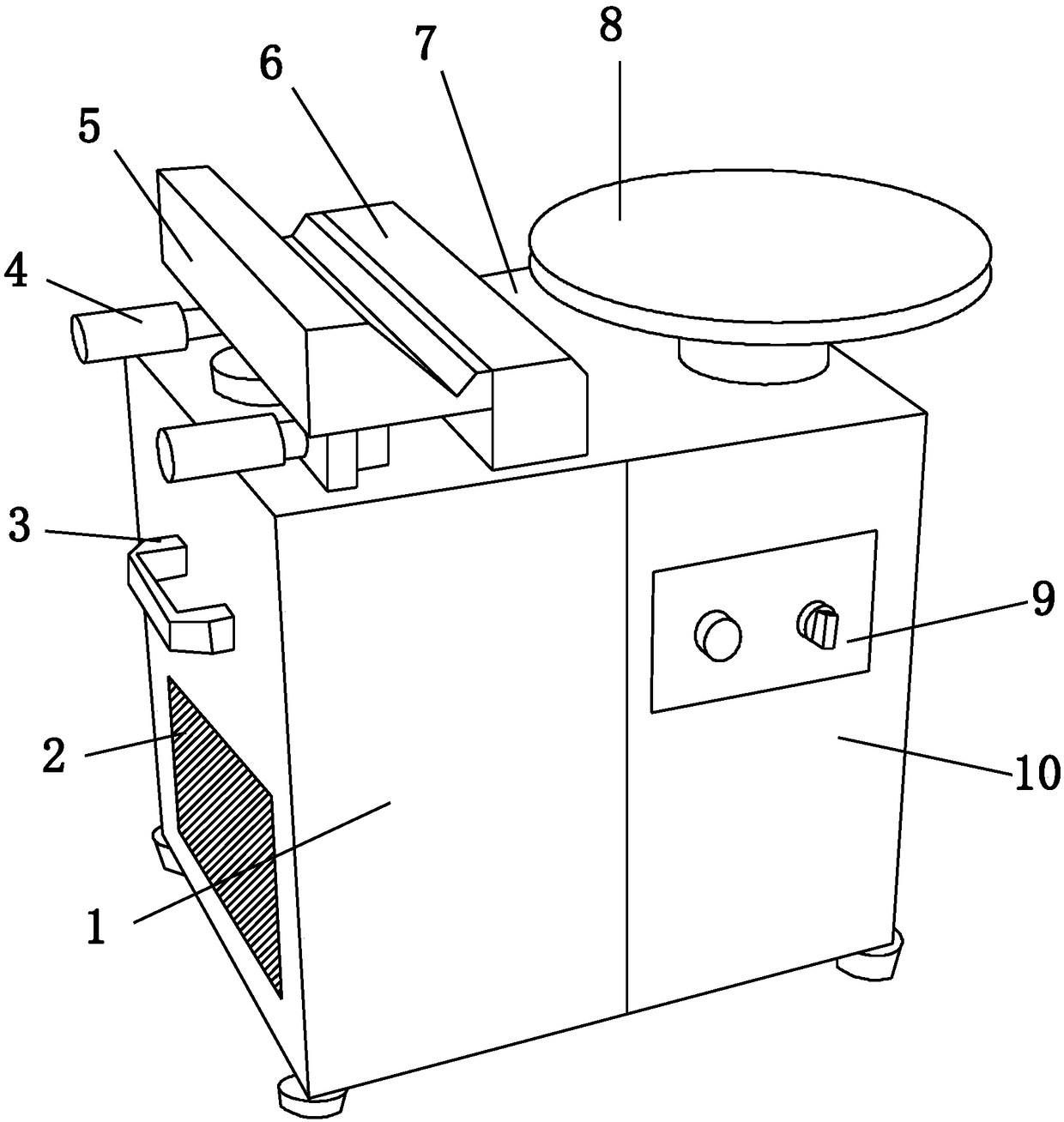

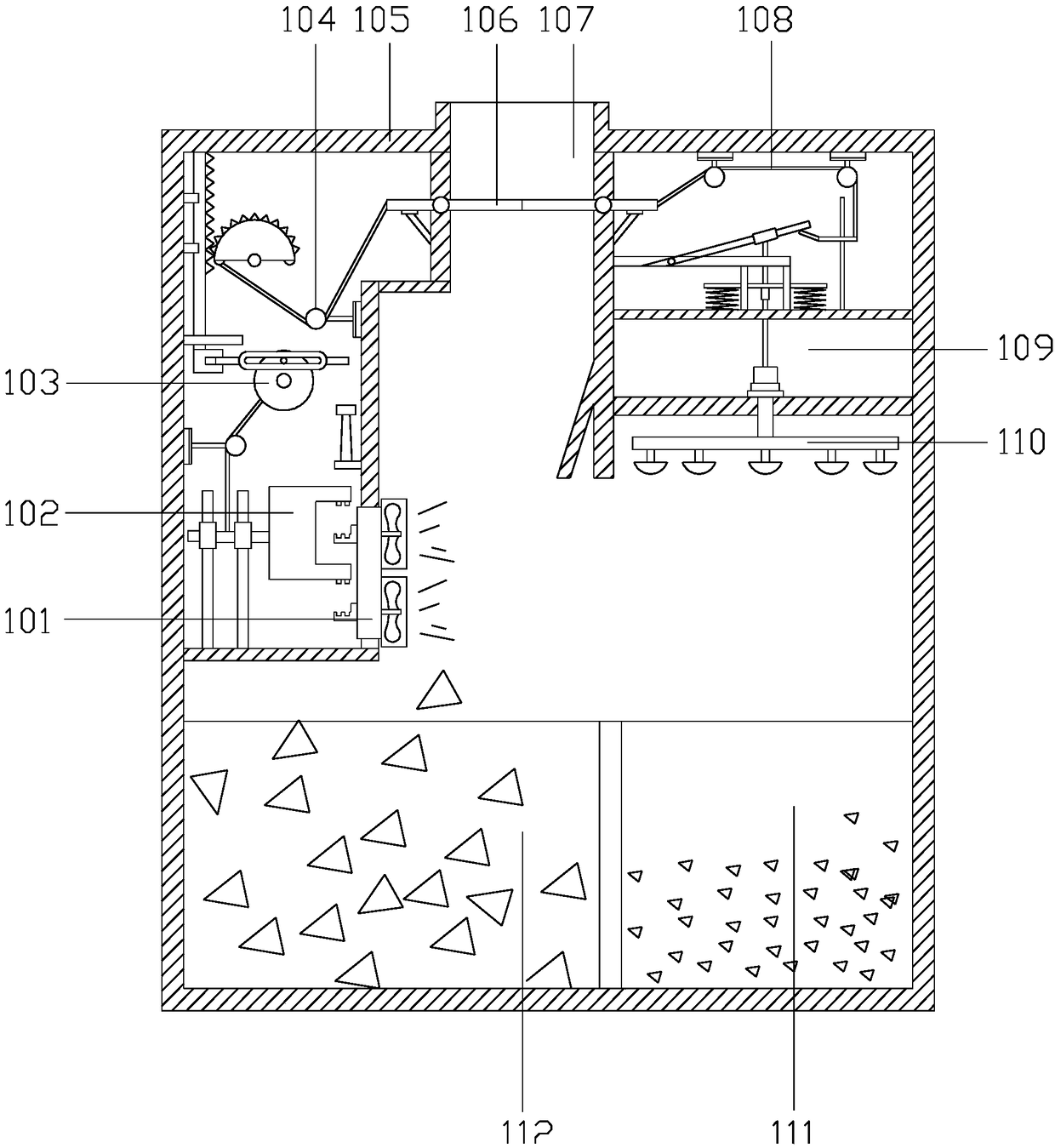

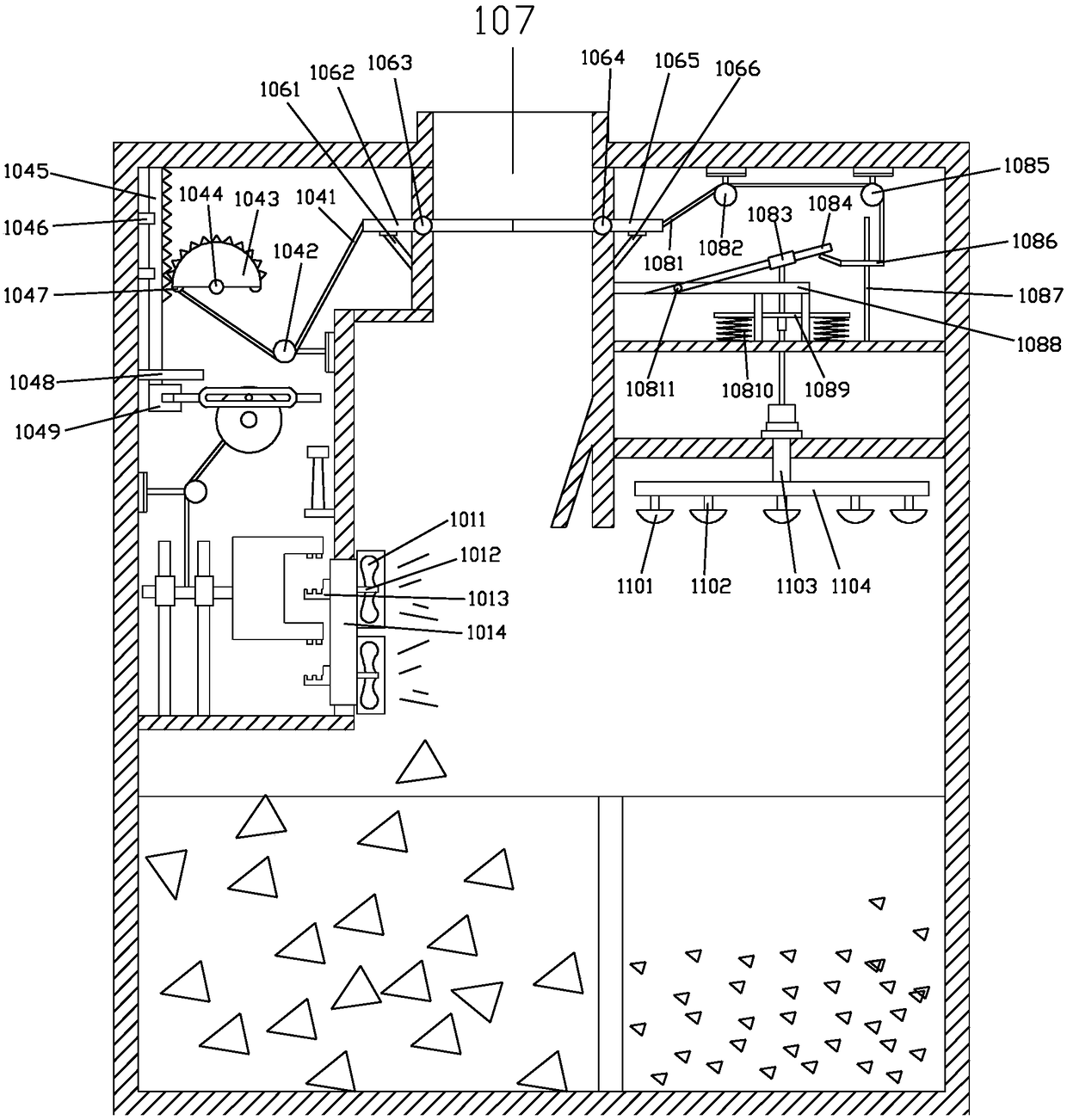

[0028] see Figure 1-Figure 8 , the present invention provides a kind of table and chair plate chamfering processing equipment: its structure comprises waste material collecting box 1, cooling groove 2, moving handle 3, regulating valve 4, protective cover 5, processing box 6, processing table top 7, workpiece turntable 8, The operation panel 9 and the processing host 10, the collection box 1 and the processing host 10 are both rectangular in structure and connected by fastening, and the left lower end of the waste collection box 1 is provided with a cooling groove 2 and is integrally formed , the moving handle 3 is installed on the left upper end of the waste collection box 1 by snap-fitting, the upper end of the surface of the processing host 10 is provided with a groove for movable installation operation panel 9, and the processing table 7 is arranged on The waste collection box 1 and the top of the processing host 10 form an integral structure, the workpiece turntable 8 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com