Durable centrifugal regenerator

A centrifugal regenerator and durable technology, applied in the field of sand treatment, can solve the problems of damage to the centrifugal disc, affecting the service life of the centrifugal regenerator, etc., to achieve the effect of ensuring quality, prolonging life, and high fatigue limit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

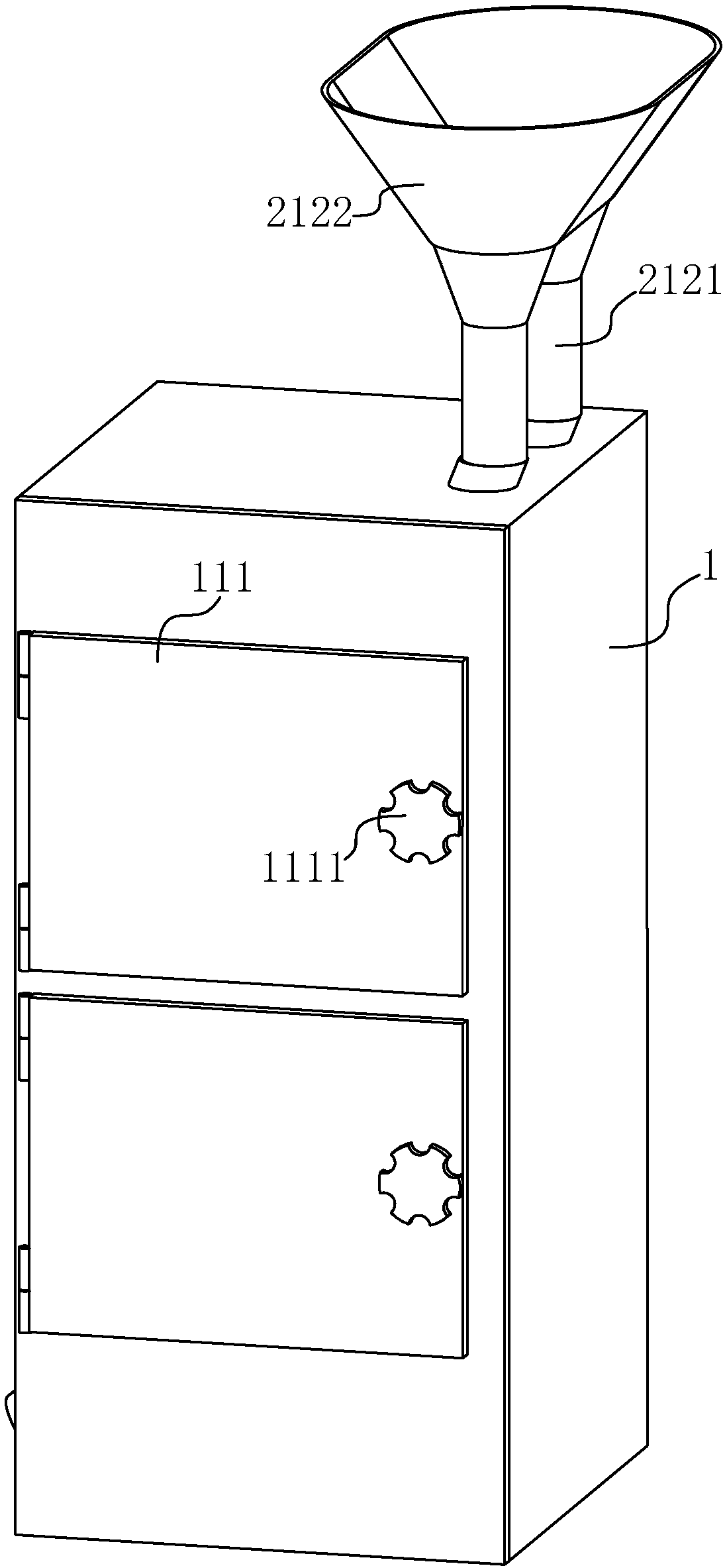

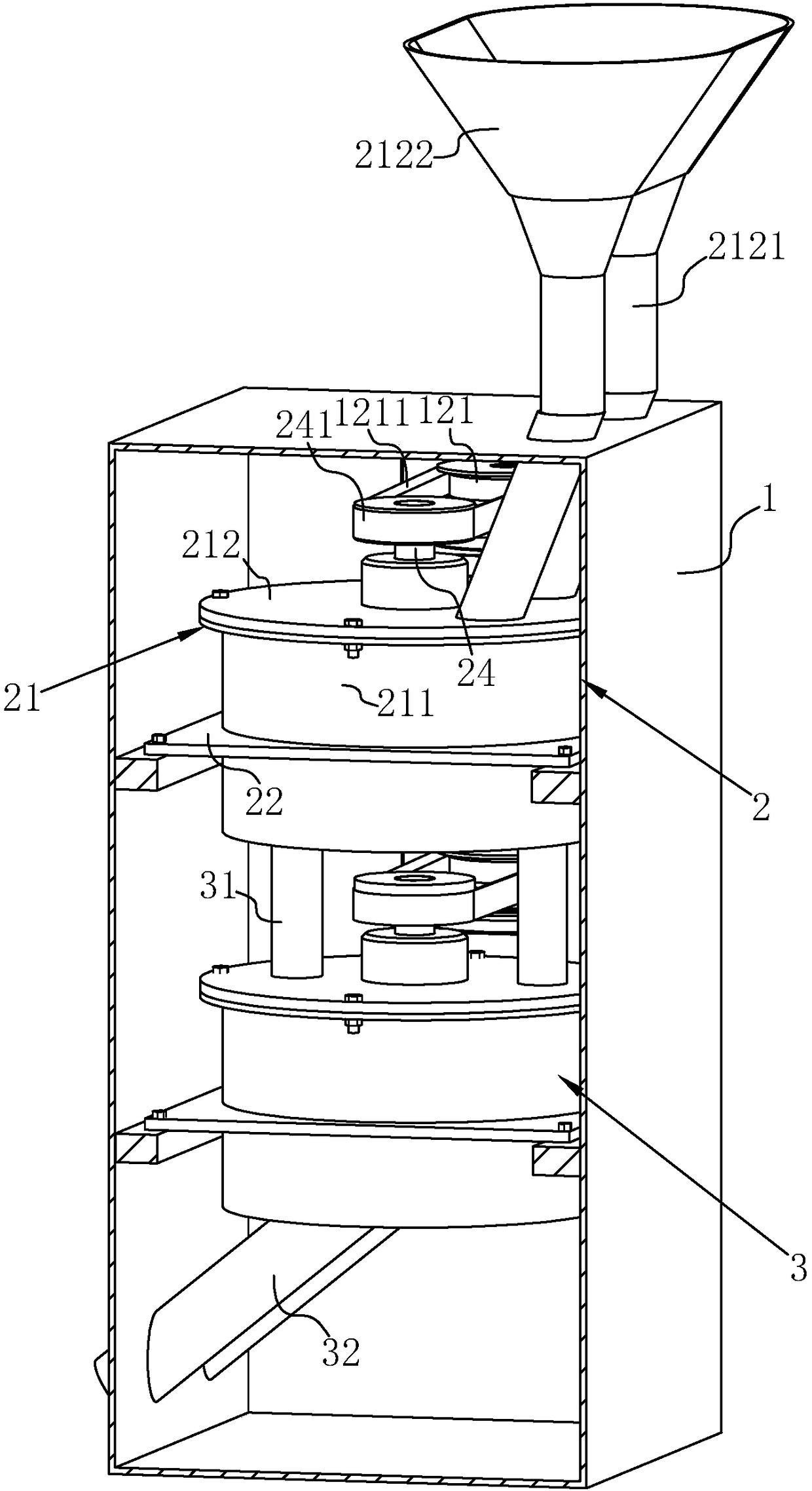

[0034] Example: A durable centrifugal regenerator incorporating figure 1 and figure 2 , including a housing 1 placed on the ground, a centrifugal regeneration device 2 connected to the housing 1, a secondary regeneration device 3 connected to the housing 1 and located below the centrifugal regeneration device 2, and the secondary regeneration device 3 is connected to the centrifugal regeneration device 2 times.

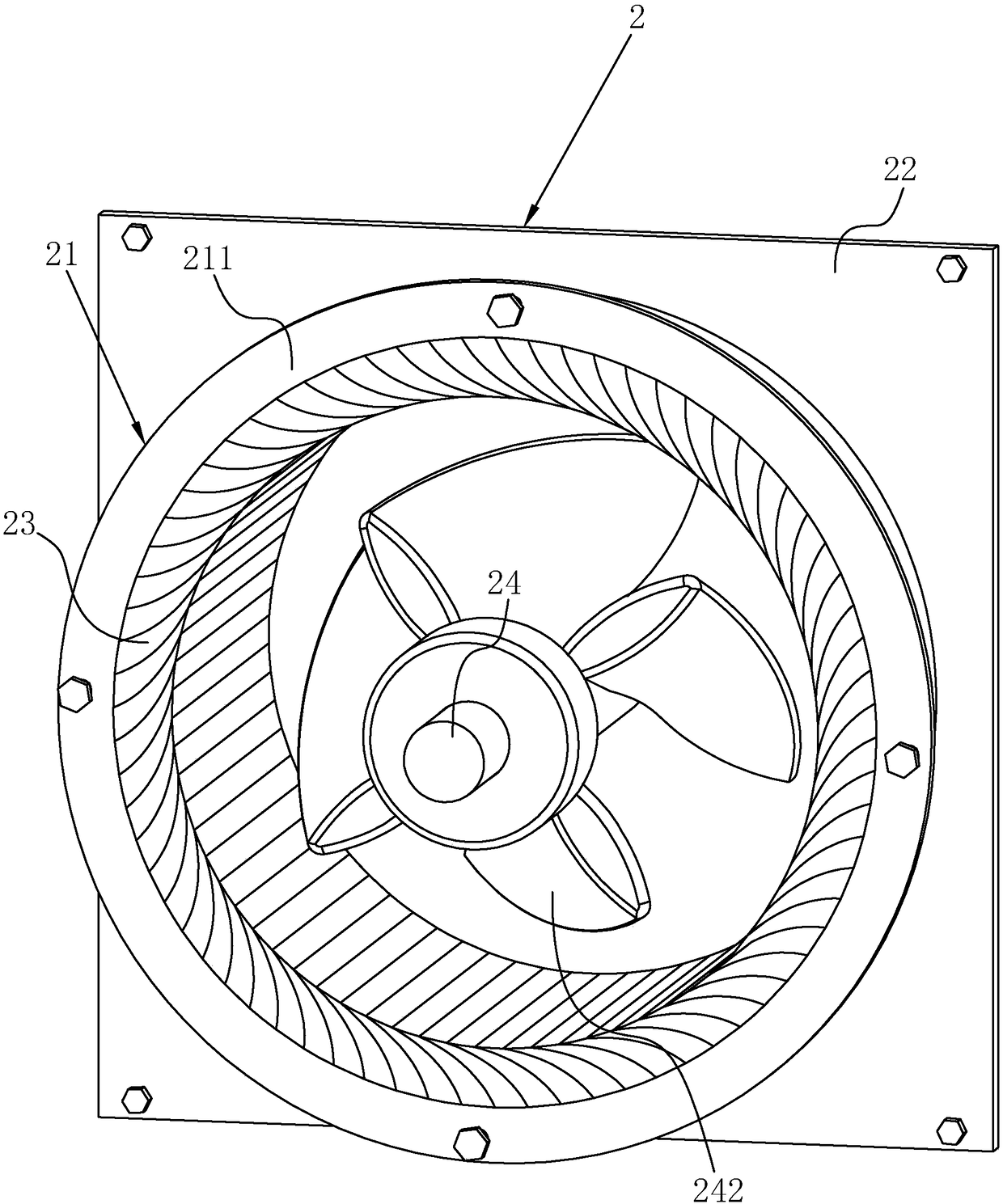

[0035] combine figure 2 and image 3 The centrifugal regeneration device 2 includes a cover body 21 connected to the casing 1 and a rotating shaft 24 rotatably connected to the middle of the cover body 21. The rotating shaft 24 is fixedly connected with a pulley 241, and the rotating shaft 24 protrudes outside the cover body 21 and the pulley 241 is fixedly connected. The part protruding from the cover body 21 on the rotating shaft 24 . Outside the housing 1 at the corresponding pulley 241 position, a motor 12 is fixedly connected (see Figure 4 ), the driving ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com