Electronic product manufacturing equipment

A technology for electronic products and equipment, applied in the field of electronic product manufacturing equipment, can solve problems such as inability to accurately absorb chips, uneven force on chips, and lower production efficiency, so as to avoid manual replacement of ejector pins, improve production efficiency, and improve production efficiency. The effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Further detailed explanation through specific implementation mode below:

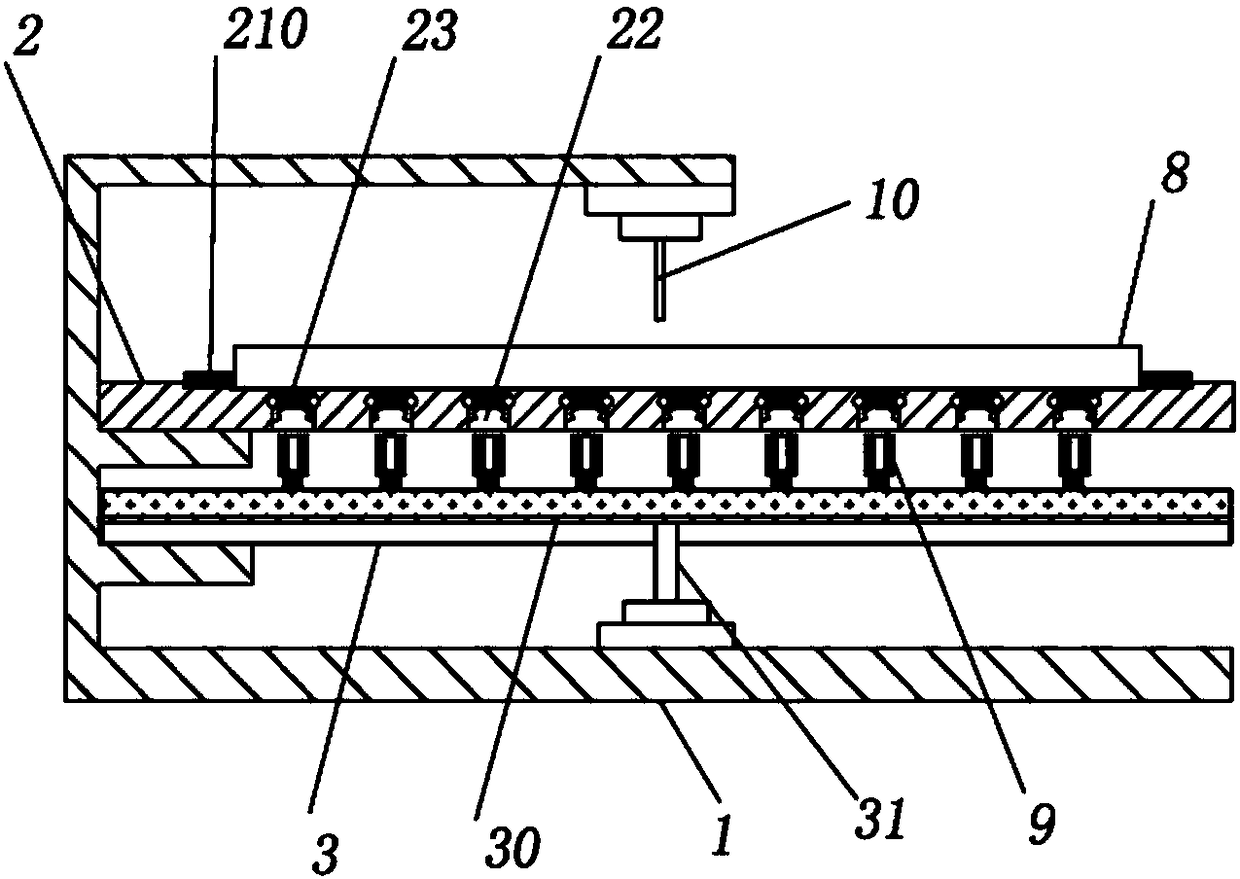

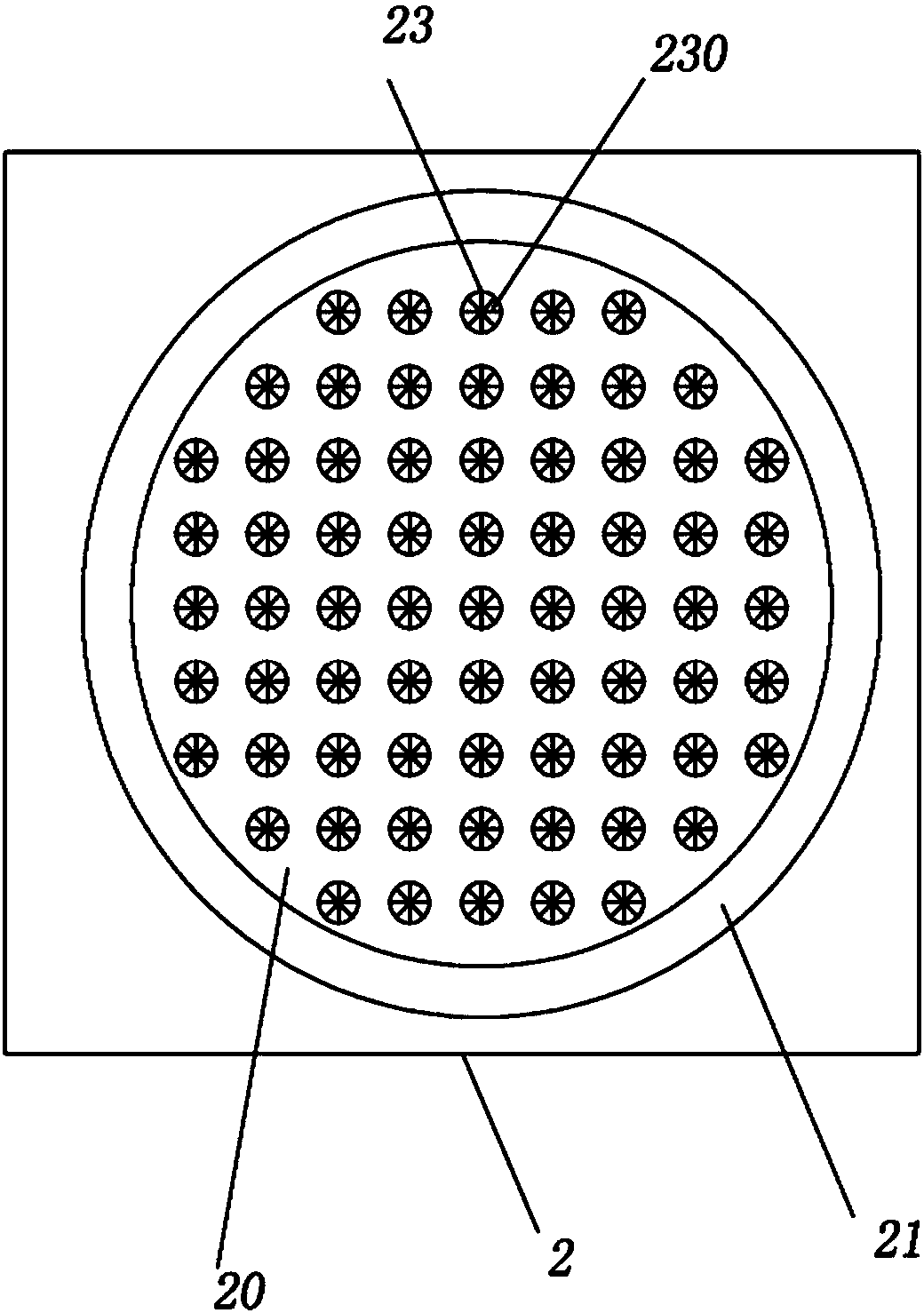

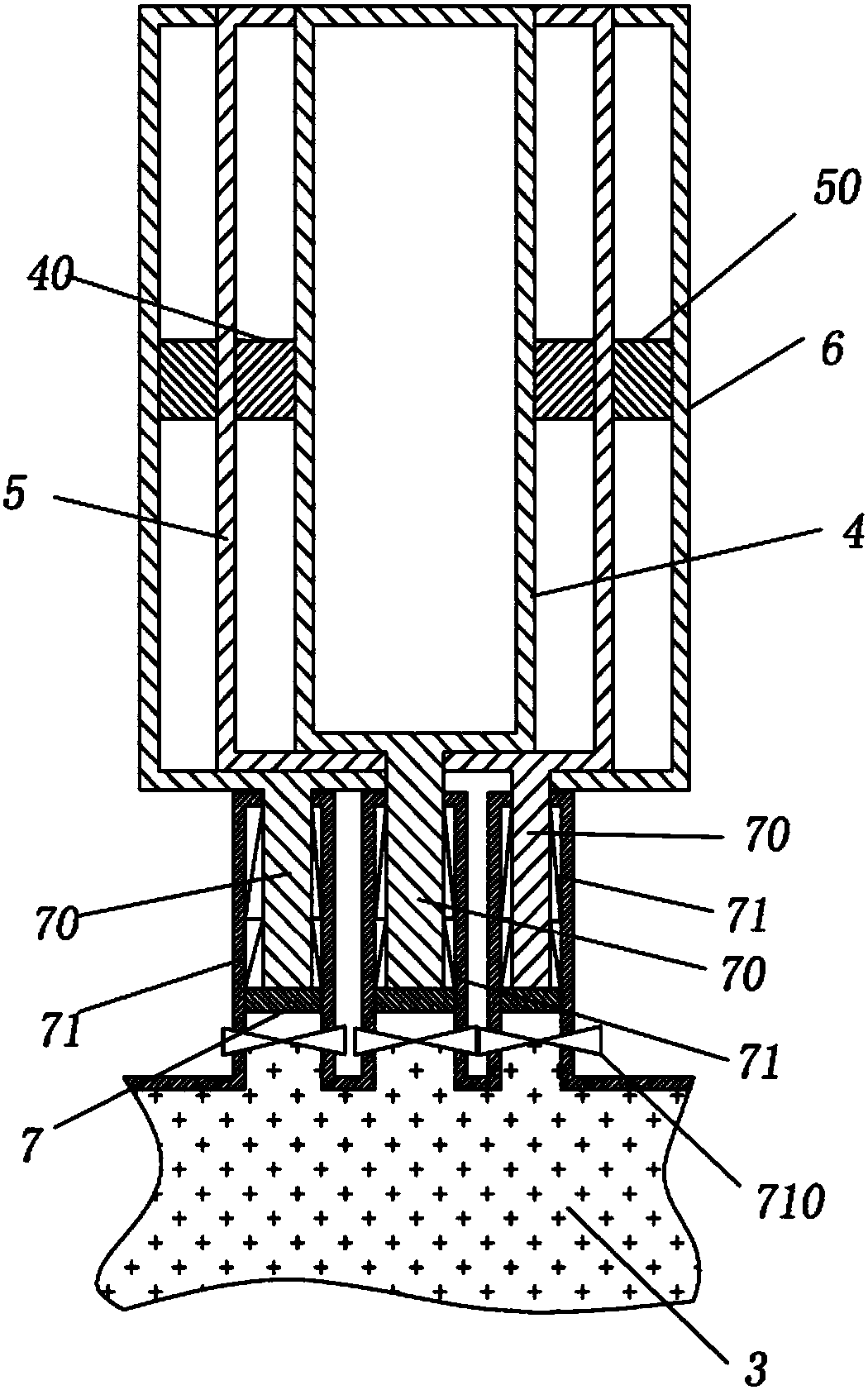

[0022] The reference signs in the drawings of the description include: frame 1, cutting knife 10, support platform 2, groove 20, iron ring placement groove 21, iron ring 210, ejection hole 22, opening and closing door 23, paging door 230, Hydraulic cylinder 3, hydraulic piston 30, cylinder 31, first ejector rod 4, first fixed ring 40, second ejector rod 5, second fixed ring 50, third ejector rod 6, push-pull piston 7, piston rod 70 , piston cylinder 71 , solenoid valve 710 , wafer 8 , ejector mechanism 9 .

[0023] The embodiment is basically as attached figure 1 Shown:

[0024] The electronic product manufacturing equipment includes a frame 1, a supporting platform 2, a pushing mechanism 9, a hydraulic cylinder 3 and a push-pull part.

[0025] A dicing knife 10 for dicing the wafer 8 is telescopically connected above the frame 1 .

[0026] The support table 2 is used to support the wafer 8, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com