A three-dimensional fracture infiltration device with adjustable gap width and internal visibility

A permeation device and slit technology, applied in the direction of measuring device, permeability/surface area analysis, suspension and porous material analysis, etc., can solve the problems of high cost, inconvenient operation, inaccurate pressure data test, etc., and achieve simple and easy operation , Accurate pressure data, and improve the effect of sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

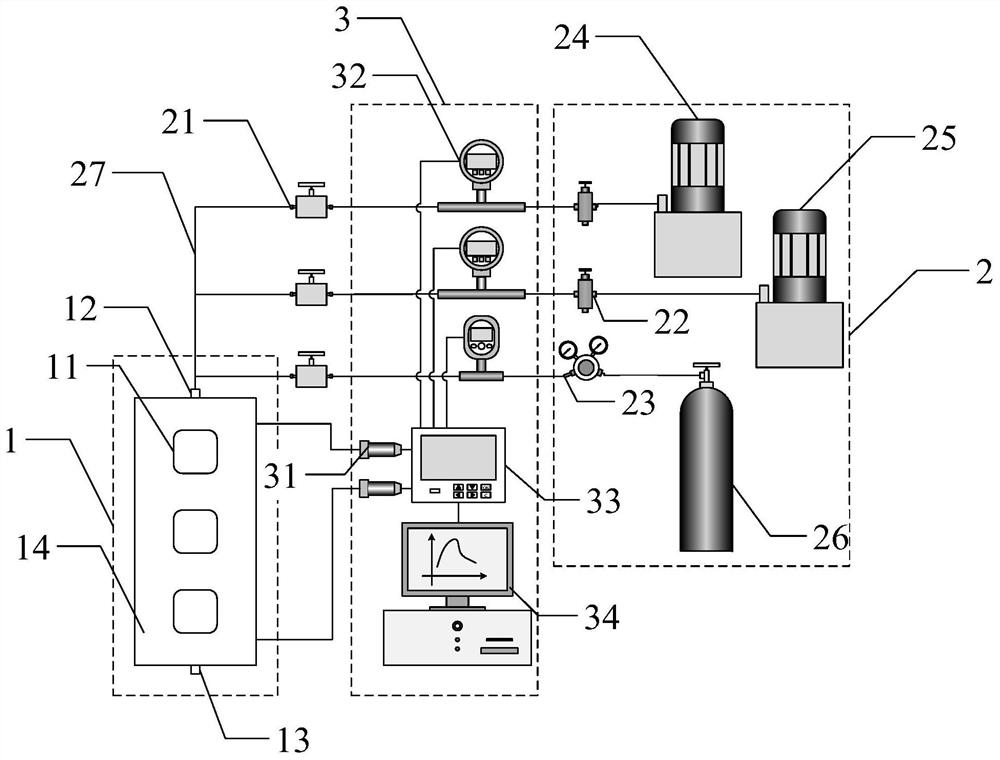

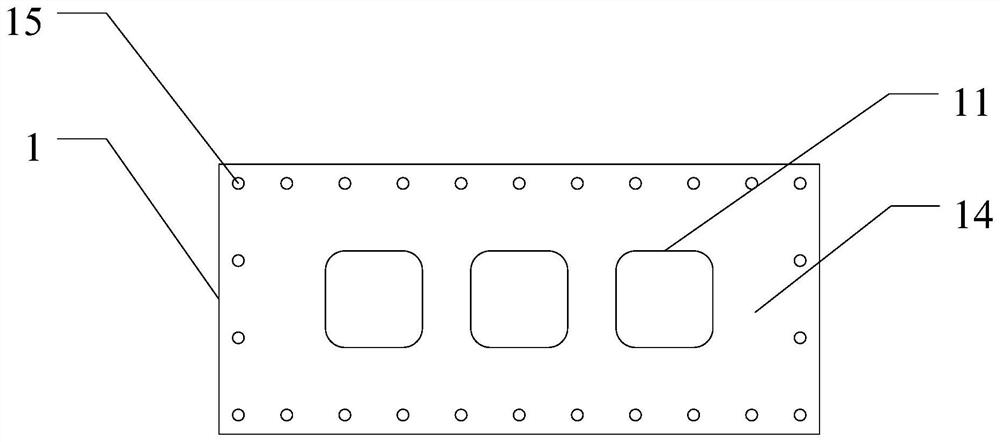

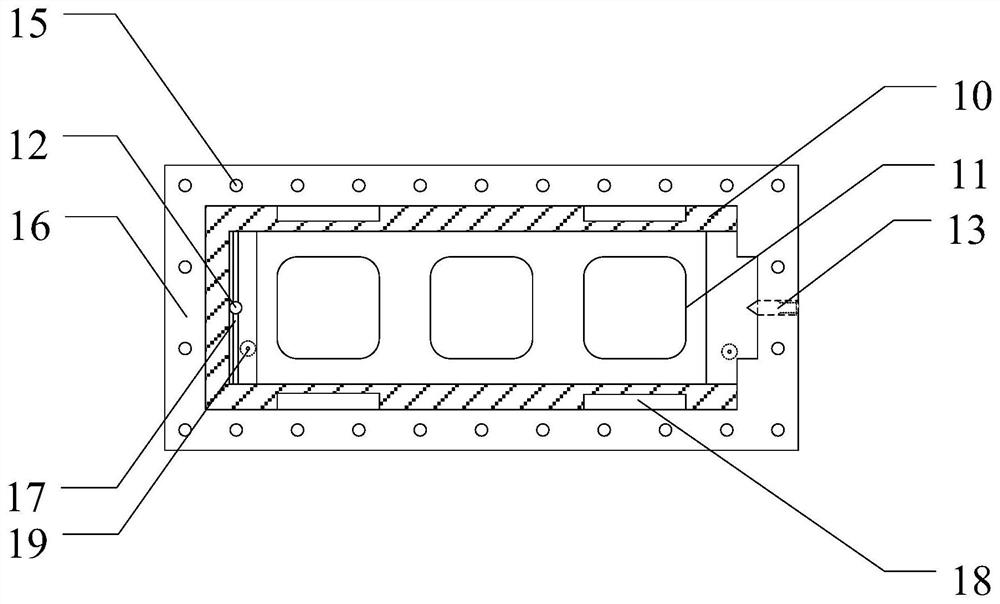

[0013] According to the drawings, the present invention provides a set of internally visible three-dimensional fracture infiltration device with adjustable gap width, which consists of three parts: a permeameter 1 , a gas-liquid supply control system 2 and a data acquisition and analysis system 3 . Among them, the fracture permeameter 1 is the main part of the three-dimensional fracture seepage device. The whole permeameter is mainly composed of an upper cover steel plate 14 with 26 high-strength bolt holes 15, a silica gel plate 10 for sealing, and two upper and lower smooth tempered glass plates. , cellophane attached to the 3D printed rough crack surface, and the bottom plate steel plate 16 are composed of five parts. A water guide channel is formed between the two tempered glass plates attached to the cellophane with the 3D printed rough crack surface, and the opening can be adjusted by using feeler gauges of different thicknesses according to the experimental requirements....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com