A water conservancy project dredging equipment

A water conservancy project and equipment technology, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, etc., can solve secondary pollution, the treatment capacity is not very large, and it is not integrated enough issues such as automation and mechanization, to achieve the effect of avoiding secondary pollution and improving the efficiency of sewage treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

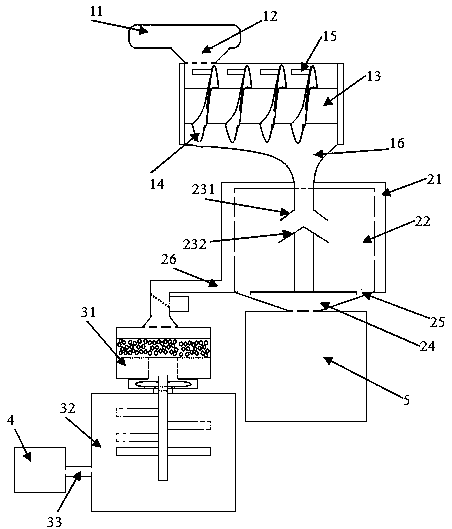

[0034] The utility model relates to dredging equipment for water conservancy projects, which includes a crushing chamber, a separation chamber, a mud storage box and sewage treatment components.

[0035] The crushing chamber includes a dredge pump, a crushing chamber casing, a crushing chamber inlet, a crushing shaft, a crushing knife, a rubber rod, and a crushing chamber outlet; The entrance of the crushing chamber is provided, and the entrance of the crushing chamber is connected with the dredge pump for pumping hydraulic engineering sludge into the crushing chamber through the suction pump. The crushing shaft is horizontally placed inside the shell of the crushing chamber, and the The crushing knife is arranged on the crushing shaft in the form of a single spiral, and a plurality of horizontal rubber rods are arranged on the top of the crushing knife (the number is the same as the number of cutting surfaces of the spiral crushing knife, and the number of cutting surfaces of ...

Embodiment 2

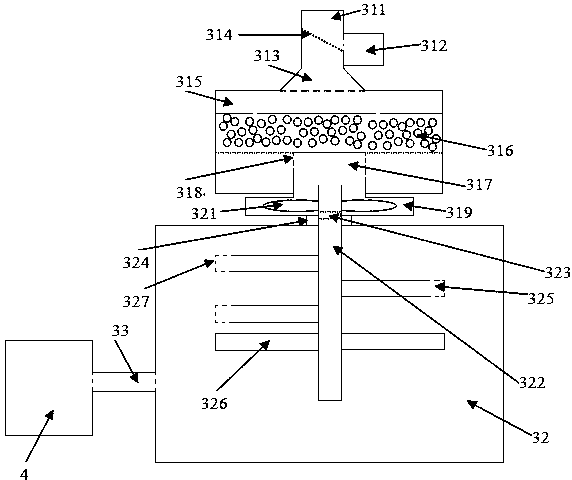

[0053] The utility model relates to dredging equipment for water conservancy projects, which includes a crushing chamber, a separation chamber, a mud storage box and sewage treatment components.

[0054] The crushing chamber includes a dredge pump, a crushing chamber casing, a crushing chamber inlet, a crushing shaft, a crushing knife, a rubber rod, and a crushing chamber outlet; The entrance of the crushing chamber is provided, and the entrance of the crushing chamber is connected with the dredge pump for pumping hydraulic engineering sludge into the crushing chamber through the suction pump. The crushing shaft is horizontally placed inside the shell of the crushing chamber, and the The crushing knife is arranged on the crushing shaft in the form of a single helix, and a plurality of horizontal rubber rods are arranged on the top of the crushing knife, and an outlet of the crushing chamber is arranged on the bottom side of the crushing chamber opposite to the entrance of the c...

Embodiment 3

[0072] The utility model relates to dredging equipment for water conservancy projects, which includes a crushing chamber, a separation chamber, a mud storage box and sewage treatment components.

[0073] The crushing chamber includes a dredge pump, a crushing chamber casing, a crushing chamber inlet, a crushing shaft, a crushing knife, a rubber rod, and a crushing chamber outlet; The entrance of the crushing chamber is provided, and the entrance of the crushing chamber is connected with the dredge pump for pumping hydraulic engineering sludge into the crushing chamber through the suction pump. The crushing shaft is horizontally placed inside the shell of the crushing chamber, and the The crushing knife is arranged on the crushing shaft in the form of a single helix, and a plurality of horizontal rubber rods are arranged on the top of the crushing knife, and an outlet of the crushing chamber is arranged on the bottom side of the crushing chamber opposite to the entrance of the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com