Green production process of uracil

A technology of green production and uracil, applied in the field of green production technology of uracil, which can solve the problem of increasing the amount of wastewater and achieve the effect that the yield and purity will not be affected

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

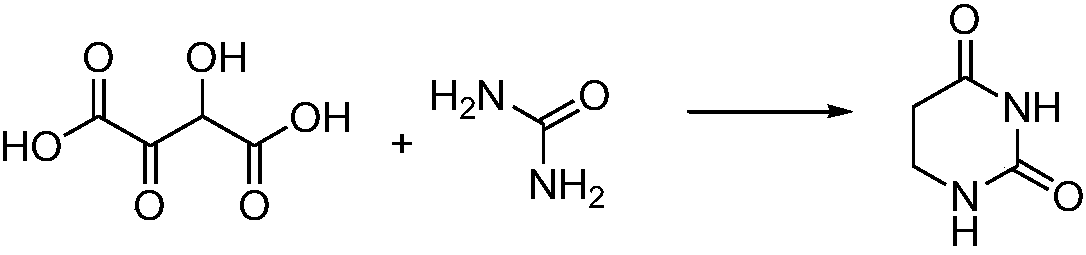

Problems solved by technology

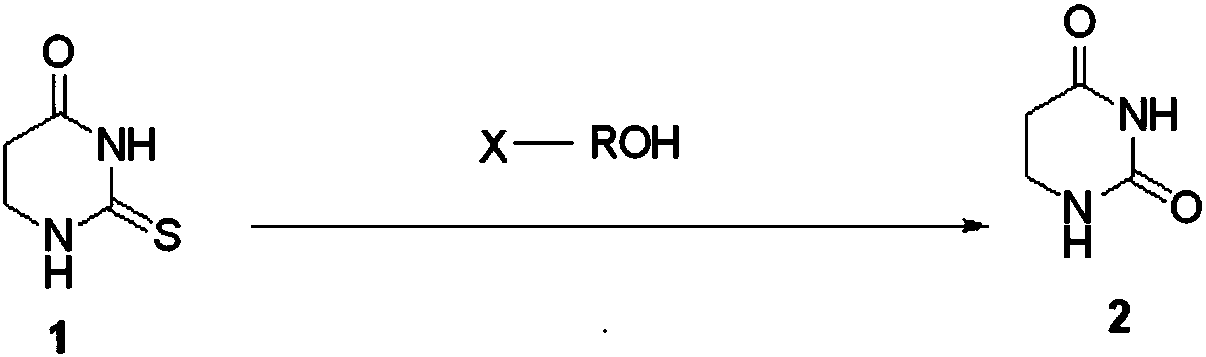

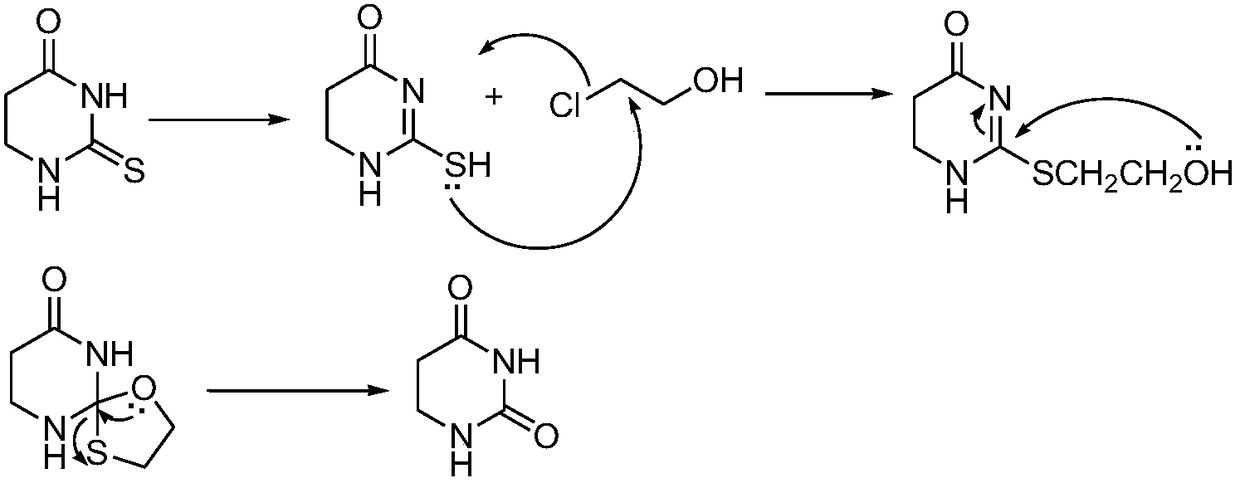

Method used

Image

Examples

Embodiment 1

[0036] Add 50 grams of thiouracil (3M) to 130 mL of water and 5.0 grams (6 equivalents) of chloroethanol, stir to raise the temperature to 100 degrees, reflux overnight, cool down slightly, analyze crystal uracil, and filter and dry. Yield 95%, purity (HPLC) 99.0%. Mother liquor continues to add 50 gram thiouracils, heats, and cycle above-mentioned operation, mother liquor can be used continuously five times. The average yield is 91%. M.P.>300°C. 1HNMR (CDCl 3 , TMS) (δ, ppm): 8.546 (d, 1H, =CH-N); 7.360 (d, 1H, =CH-C). Purity was not affected (see table below).

[0037] Mother liquor cycle times

Embodiment 2

[0039] Add 50 grams of thiouracil (3M) to 130 mL of water and 5.0 grams (6 equivalents) of bromoethanol, stir to raise the temperature to 100 degrees, reflux overnight, cool down slightly, analyze crystal uracil, and filter and dry. Yield 85%, purity (HPLC) 99.1%. Mother liquor continues to add 50 gram thiouracils, heating, cycle above-mentioned operation, mother liquor can use five times continuously. The average yield is 80%; M.P.>300℃. 1HNMR (CDCl 3 , TMS) (δ, ppm): 8.546 (d, 1H, =CH-N); 7.360 (d, 1H, =CH-C). Purity was not affected (see table below). Purity has little effect.

[0040]

[0041]

Embodiment 3

[0043] Add 50 grams of thiouracil (3M) to 130 mL of water and 5.0 grams (6 equivalents) of chloroacetic acid, stir to raise the temperature to 100 degrees, reflux overnight, cool down slightly, analyze crystal uracil, and filter and dry. Yield 90%, purity (HPLC) 99.0%. Mother liquor continues to add 50 gram thiouracils, heating, cycle above-mentioned operation, mother liquor can use five times continuously. The average yield is 94%; M.P.>300°C. 1HNMR (CDCl 3 , TMS) (δ, ppm): 8.546 (d, 1H, =CH-N); 7.360 (d, 1H, =CH-C). Purity was not affected (see table below). Purity is not affected.

[0044] Mother liquor cycle times

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com