High tower seaweed nitrate-sulfate base compound fertilizer

A compound fertilizer and nitrosulfur-based technology, applied in the direction of organic fertilizers, inorganic fertilizers, fertilizer mixtures, etc., can solve the problems of inability to implant seaweed extracts, etc., and achieve the effect of improving crop growth rate and good fertilizer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

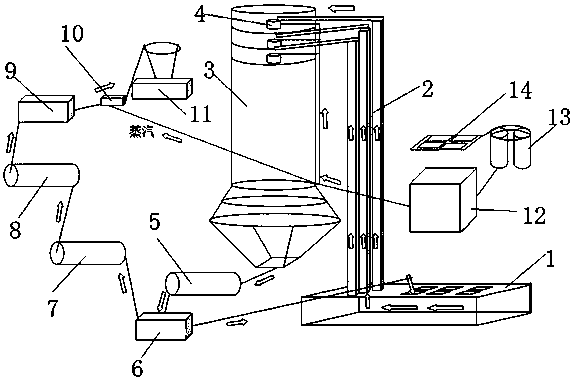

Image

Examples

Embodiment 1

[0015] Embodiment 1: This embodiment adopts the following technical scheme: high-tower seaweed nitrosulfur-based compound fertilizer, composed of the following raw materials in weight ratio: 16 parts of phosphorus nitrate, 12 parts of monoammonium phosphate, 22 parts of potassium sulfate, 32 parts of seaweed extract 25 parts, seaweed residue.

[0016] The preparation method of high-tower seaweed nitrosulfur-based compound fertilizer comprises the following steps:

[0017] 1. Put all the materials from the feeding port: 16 parts of phosphorus nitrate, 12 parts of monoammonium phosphate, 22 parts of potassium sulfate, 32 parts of seaweed extract, and 25 parts of seaweed residue are put into the feeding port together, and are transported to the high tower reaction through bucket elevator kettle;

[0018] 2. The first tank in the high tower reactor dissolves ammonium nitrate phosphorus, the second tank is compounded with monoammonium phosphate, and the third tank is compounded wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com