Polypyrrole-modified ag-pd bimetallic composite electrocatalytic cathode and its preparation method and application

A technology of polypyrrole and electrocatalysis, applied in chemical instruments and methods, water/sludge/sewage treatment, sterilization/microdynamic water/sewage treatment, etc., can solve the problem of high price of electrocatalytic cathode, low catalyst efficiency, Short service life and other problems, to achieve good electrocatalytic reduction degradation effect, strong binding force, and improve catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] A preparation method of a polypyrrole-modified Ag-Pd bimetallic composite electrocatalytic cathode, comprising the following steps:

[0040] Step 1, the Ti sheet was polished with 100-grit sandpaper, and then ultrasonically cleaned in acetone, absolute ethanol and deionized water for 10 min for decontamination, and then placed in a mixed solution of boiled concentrated hydrochloric acid and water with a volume ratio of 1:2 for 15 min, and finally rinsed with deionized water to obtain a Ti matrix.

[0041] Step 2, using water as a solvent, prepare a mixed solution containing 90-100 mmol / L of pyrrole, 3-7 mmol / L of sodium dodecylbenzene sulfonate, and 0.2-0.5 mmol / L of sulfuric acid as a sedimentation solution, using the obtained solution in step 1. The titanium sheet is the anode and the platinum sheet is the cathode. Under the conditions of a deposition current of 12-15 mA and a deposition time of 10-12 min, a polypyrrole / Ti supporting electrode is obtained by electrode...

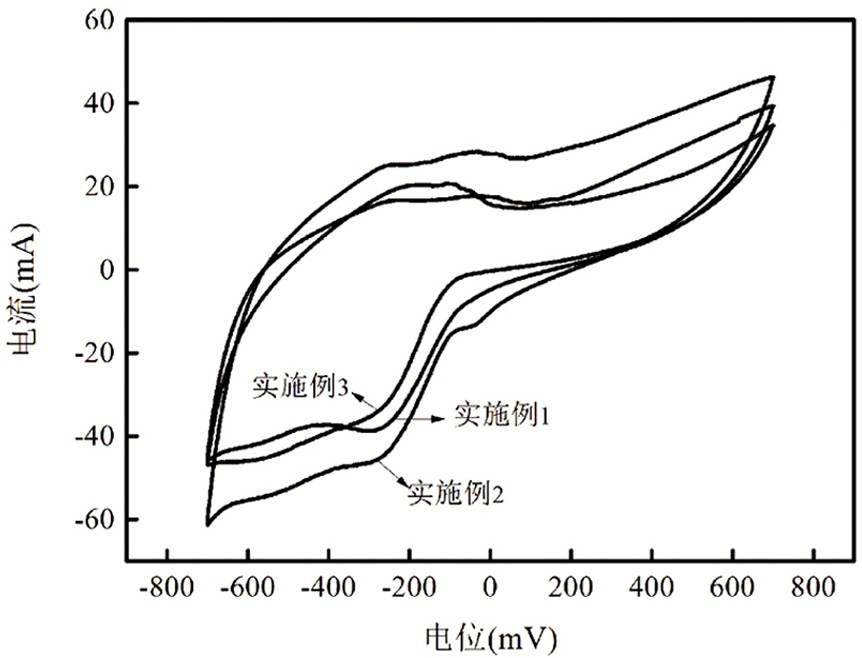

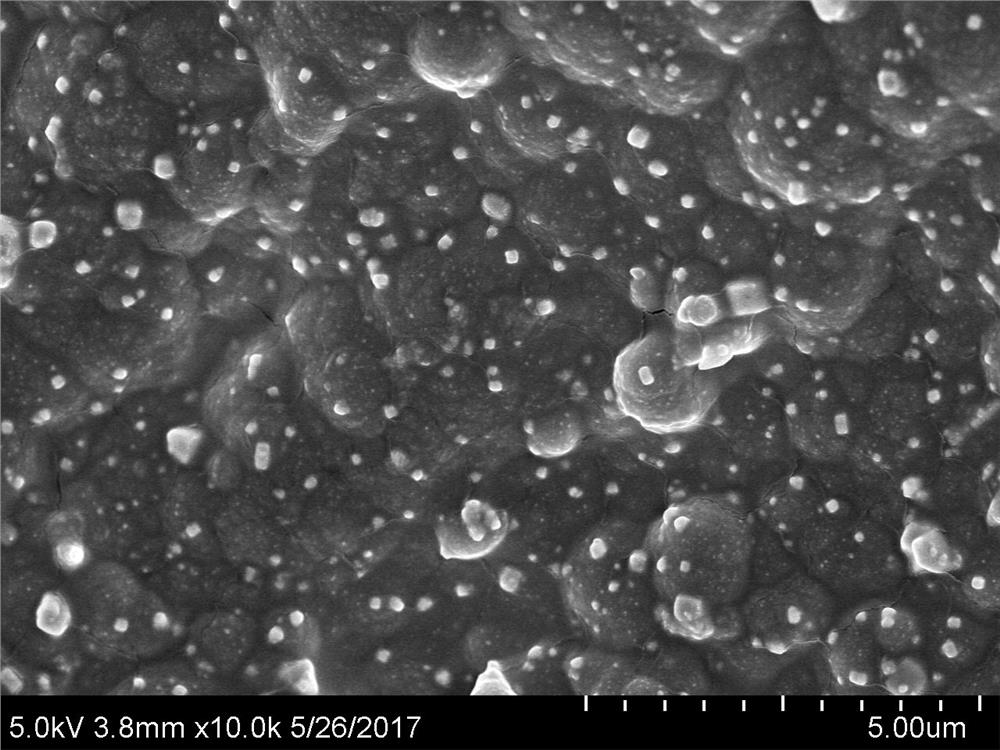

Embodiment 1

[0052] A polypyrrole-modified Ag-Pd bimetallic composite electrocatalytic cathode, the specific preparation steps of which are as follows:

[0053] Step 1, the Ti sheet was polished with 100-grit sandpaper, and then decontaminated by ultrasonic cleaning in acetone, absolute ethanol and deionized water for 10 minutes, and then placed in a mixed solution of boiling hydrochloric acid: water = 1:2 for 15 minutes, Finally, it was cleaned with deionized water to obtain a Ti substrate.

[0054] Step 2, using water as a solvent, prepare a mixed solution containing 90 mmol / L of pyrrole, 3 mmol / L of sodium dodecyl benzene sulfonate, and 0.2 mmol / L of sulfuric acid as a deposition solution, using the titanium sheet obtained in step 1 as an anode, platinum The sheet is the cathode, and under the conditions of deposition current of 12mA and deposition time of 10min, the polypyrrole / Ti supporting electrode was obtained by electrodeposition.

[0055] Step 3, place the polypyrrole modified e...

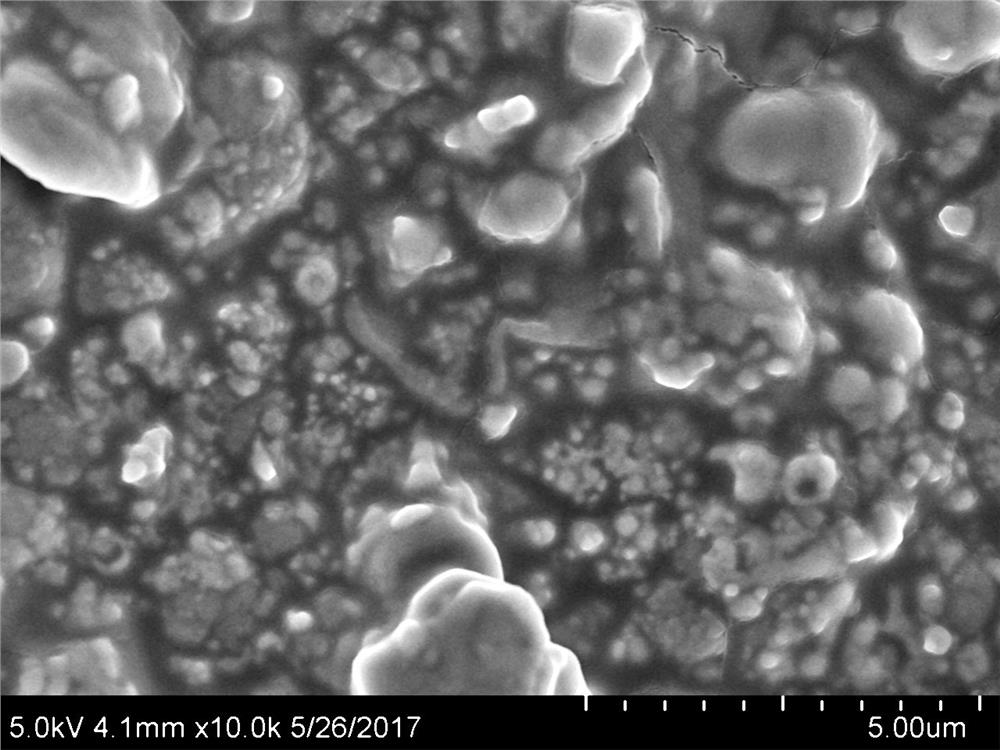

Embodiment 2

[0060] A polypyrrole-modified Ag-Pd bimetallic composite electrocatalytic cathode, the specific preparation steps are as follows:

[0061] Step 1: Polish the Ti sheet with 100-grit sandpaper, then ultrasonically clean it in acetone, absolute ethanol and deionized water for 10 min to decontaminate, and then place it in a mixed solution of boiling concentrated hydrochloric acid: water = 1:2 for 15 min , and finally cleaned with deionized water to obtain a Ti substrate.

[0062]Step 2, using water as a solvent, prepare a mixed solution containing 95 mmol / L of pyrrole, 5 mmol / L of sodium dodecyl benzene sulfonate, and 0.3 mmol / L of sulfuric acid as a deposition solution, using the titanium sheet obtained in step 1 as an anode, platinum The sheet is the cathode, and under the conditions of deposition current of 13mA and deposition time of 11min, the polypyrrole / Ti supporting electrode was obtained by electrodeposition.

[0063] Step 3, place the polypyrrole modified electrode obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com