Automatic winding and bagging machine for infusion set and working method thereof

A technology of tube bagging machine and infusion set, which is applied in the field of medical equipment, can solve the problems of high labor cost, low work efficiency, flattening of tubes, etc., and achieve the effect of reasonable structure design, simple structure and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

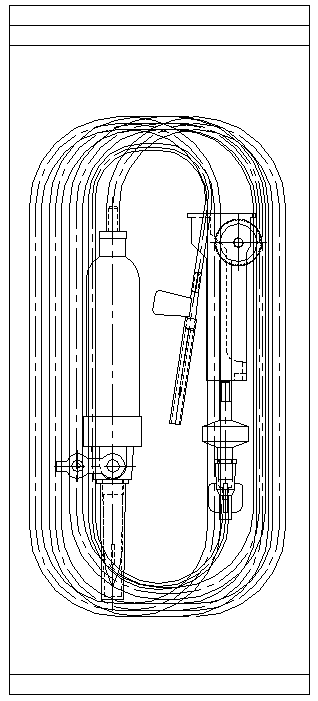

[0054] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0055] see Figure 4 to Figure 26 .

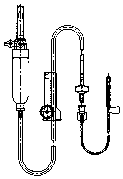

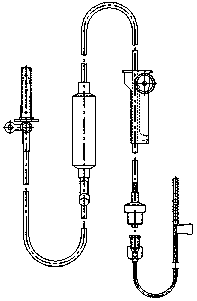

[0056] Such as Figure 4 As shown, an infusion set automatic tube-winding bagging machine in an embodiment of the present invention is composed of an infusion set suspension conveying device 1, a transfer and handover mechanism 2, an infusion set tube winding device 3, and an infusion set bagging and sealing device 5. combined.

[0057] In the embodiment of the present invention, the hanging delivery device 1 for the infusion set includes a rotary delivery mechanism 11 , an automatic alignment and positioning mechanism 12 for the lower part after suspension, and a vertical online leak detection mechanism 13 . After hanging, the lower part automatically aligns the positioning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com