An assembly method for an aircraft to assemble an omni-axial thermal protection component

An assembly method and thermal protection technology, which is applied in aircraft assembly, aircraft component testing, etc., can solve the problem that aircraft thermal protection components cannot be assembled accurately, and achieve the effect of ensuring accurate assembly method, strong operability, and precise position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the purpose, content and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail.

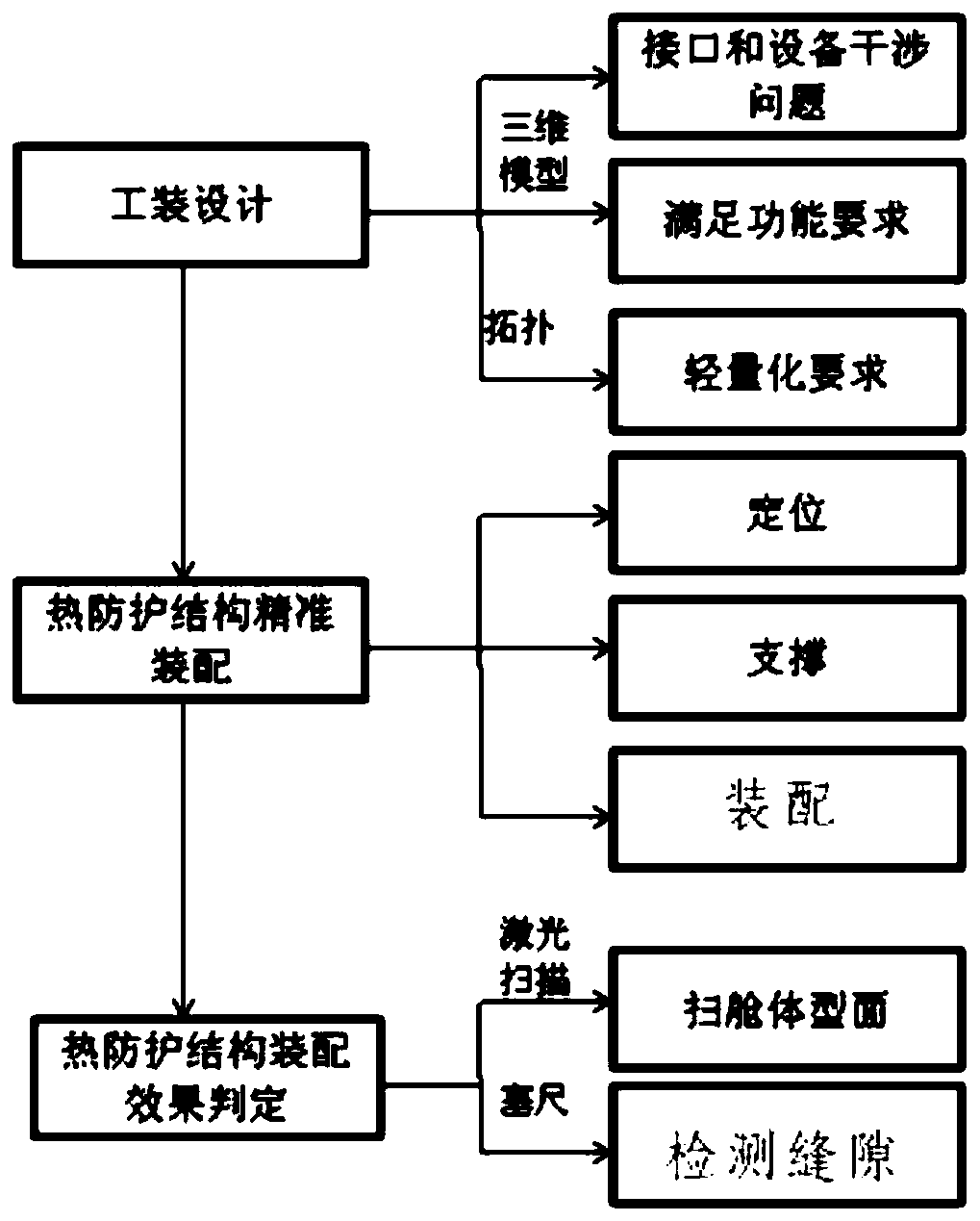

[0017] With the background of a three-axis precise assembly method for a thermal protection structure of an aircraft, the present invention provides an assembly method for assembling an omni-axial thermal protection component of an aircraft, which specifically includes the following steps:

[0018] S1. According to the installation requirements proposed by the design, the thermal protection components are installed on the lower surface of the No. 2 cabin, and the assembly sequence of the thermal protection components is confirmed. The installation sequence is as attached figure 1 As shown, the order of disassembly is just opposite to the order of installation;

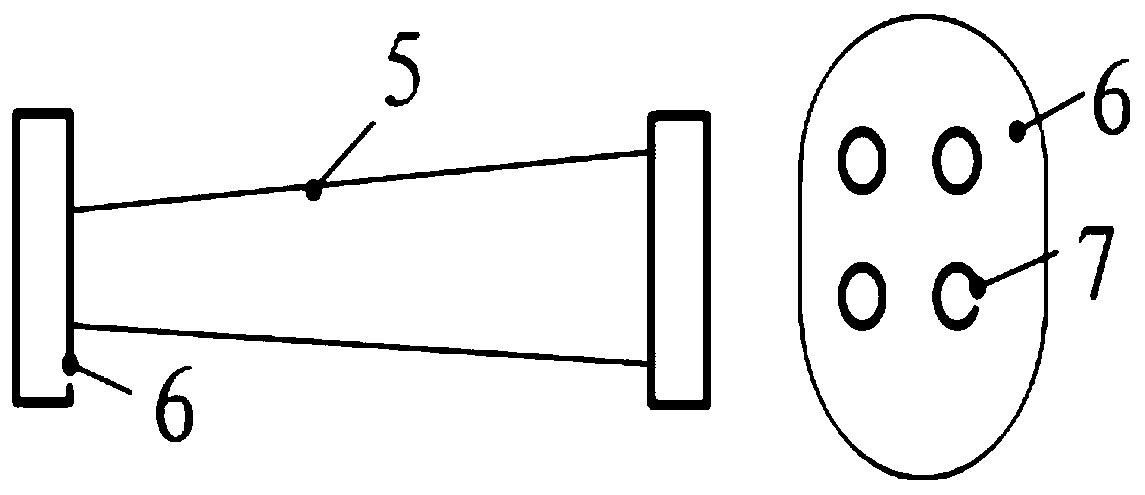

[0019] S2. Determine the overturning tooling of the aircraft in all axial directions, the overturning tooling 5 can clamp the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com