Improved metal carving device

An improved metal technology, applied in the field of engraving, can solve the problems of affecting the quality of engraving and increasing the difficulty of engraving work, and achieve the effect of safe and stable clamping and fixing, satisfying engraving operation, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

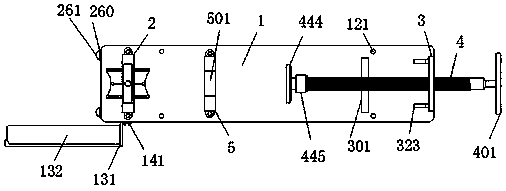

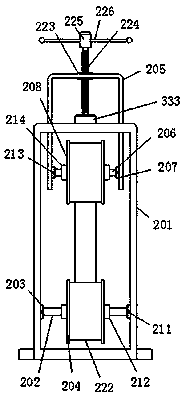

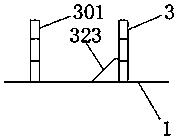

[0021] refer to Figure 1-3 As shown, an improved metal engraving device of the present invention includes a platen 1, a positioning clamping device 2 is provided at the top of the platen 1 against the left side, and a positioning clamping device 2 is provided at the top right side of the platen 1. A vertical plate 3 is provided, and a screw hole (not shown) is opened in the vertical plate 3, and a first screw rod 4 is fitted through the screw hole, and the right end of the first screw rod 4 is provided with a first rotation The handle 401, the left end of the first screw rod 4 is provided with a push slide 444, the top of the table 1 is fixedly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com