Building brick shape-fixing cutting equipment

A technology for construction and bricks, which is applied to stone processing equipment, stone processing tools, work accessories, etc., can solve the problems of inability to cut obliquely, reduce the life of cutting saw blades, and waste, so as to facilitate stereotyped cutting, The effect of reducing work errors and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

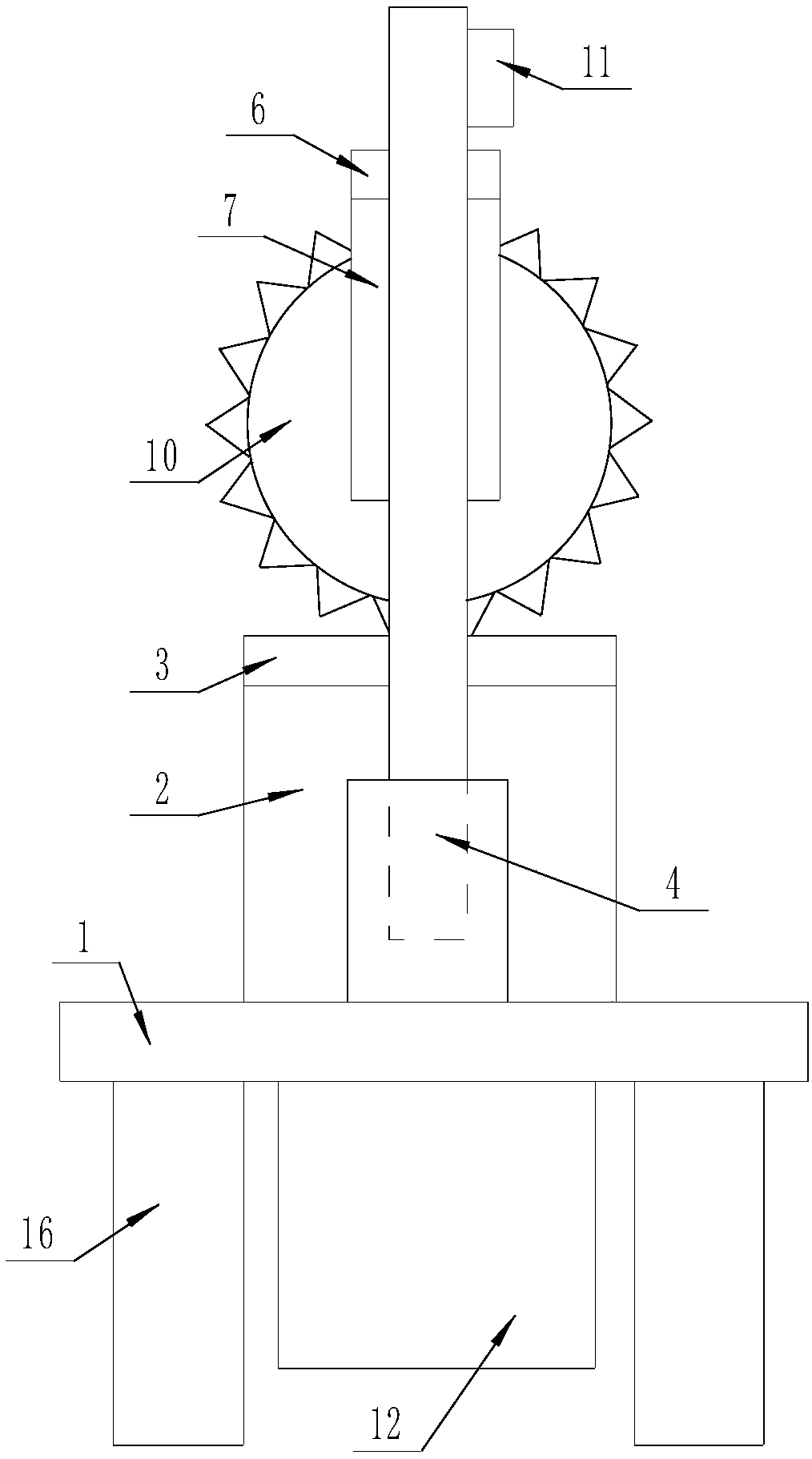

[0014] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-2 As shown, a kind of stereotyped brick cutting equipment for construction, including a mounting base 1, a pair of L-shaped positioning plates 2 are fixedly connected to both ends of the upper surface of the mounting base 1, and the upper surface of each of the L-shaped positioning plates 2 is fixed A fixed pressure plate 3 is connected, the upper surface of the mounting seat 1 is fixedly connected with an electric control telescopic gantry frame 4, and the lower surface of the crossbeam of the electric control telescopic gantry frame 4 is fixedly connected with a horizontal slide rail 5, and the horizontal slide rail 5 is fixedly connected with the horizontal slide rail 5. The lower surface of the rail 5 is provided with an electronically controlled mobile slider 6, and the lower surface of the electrically controlled mobile slider 6 is fixedly connected with a d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com