Gantry type cleaning device for pipeline cleaning equipment

A pipeline cleaning and cleaning device technology, which is applied in the directions of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of different thickness of pipeline sand, long pipeline length, affecting treatment effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

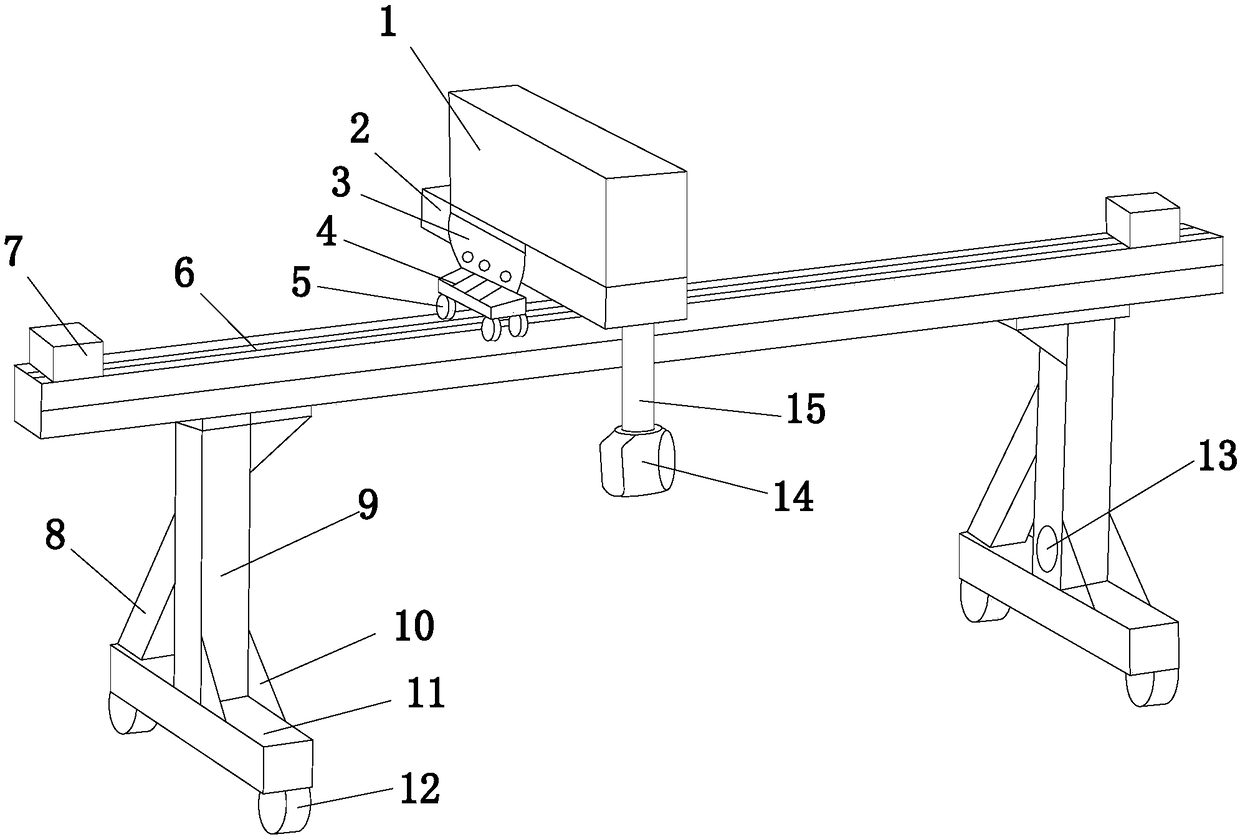

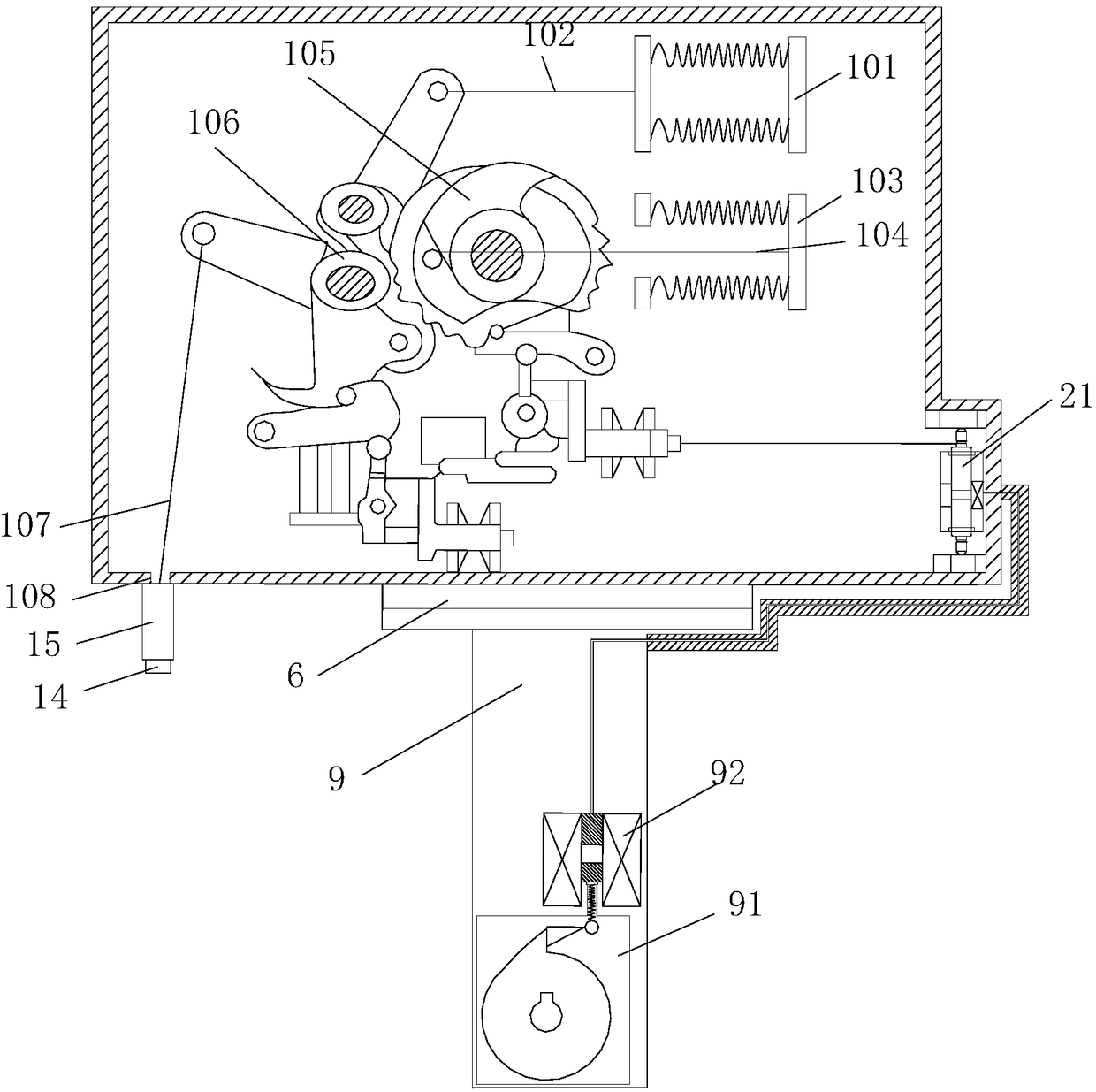

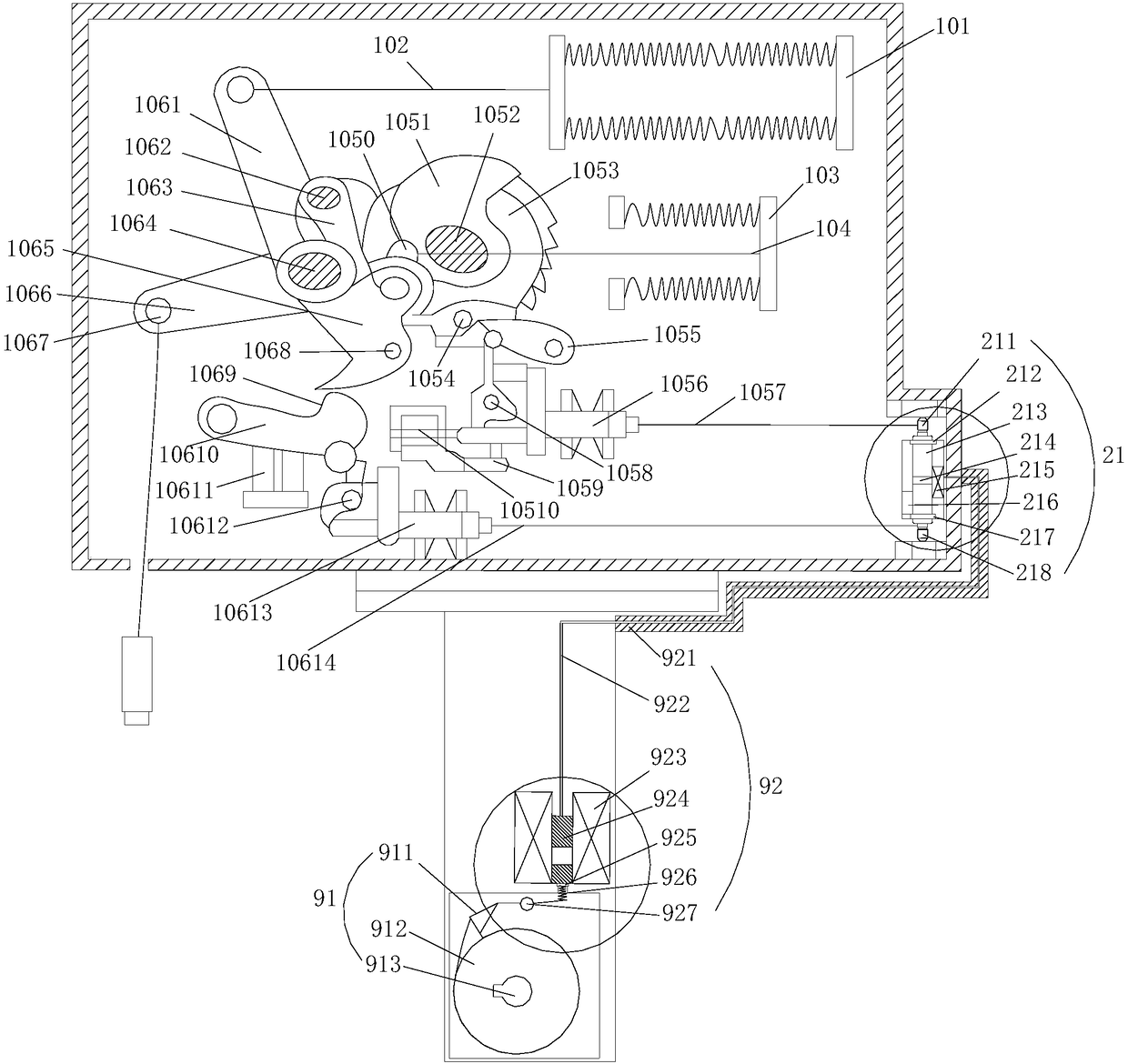

[0027] see Figure 1-Figure 5 , the present invention provides a gantry type cleaning device for pipeline cleaning equipment, its structure includes a control drive device 1, a circuit breaker 2, a fixed steel plate 3, a sliding fixed block 4, a moving wheel 5, a moving track 6, a limit block 7. The first support plate 8, the support column 9, the second support plate 10, the base 11, the universal wheel 12, the steel pipe fixed joint 13, the cleaner 14, the connecting rod 15, and the bottom of the left and right ends of the moving track 6 are vertical Connected with a support column 9, the bottom end of the support column 9 is vertically welded on the base 11, the first support plate 8 and the second support plate 10 are triangular structures and one end is used to fix the support column 9, the first The support plate 8 and the other end of the second support plate 10 are welded on the base 11, the two sides of the bottom end of the base 11 are mechanically connected with uni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com