Automatic quantitative gradient sample adding type multichannel pipettor piston assembly

A technology for a piston assembly and a pipette, which is applied in the field of multi-channel pipettes, can solve the problem that multi-channel pipettes cannot perform gradient addition, and achieves the effect of avoiding human error and omitting cumbersome operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

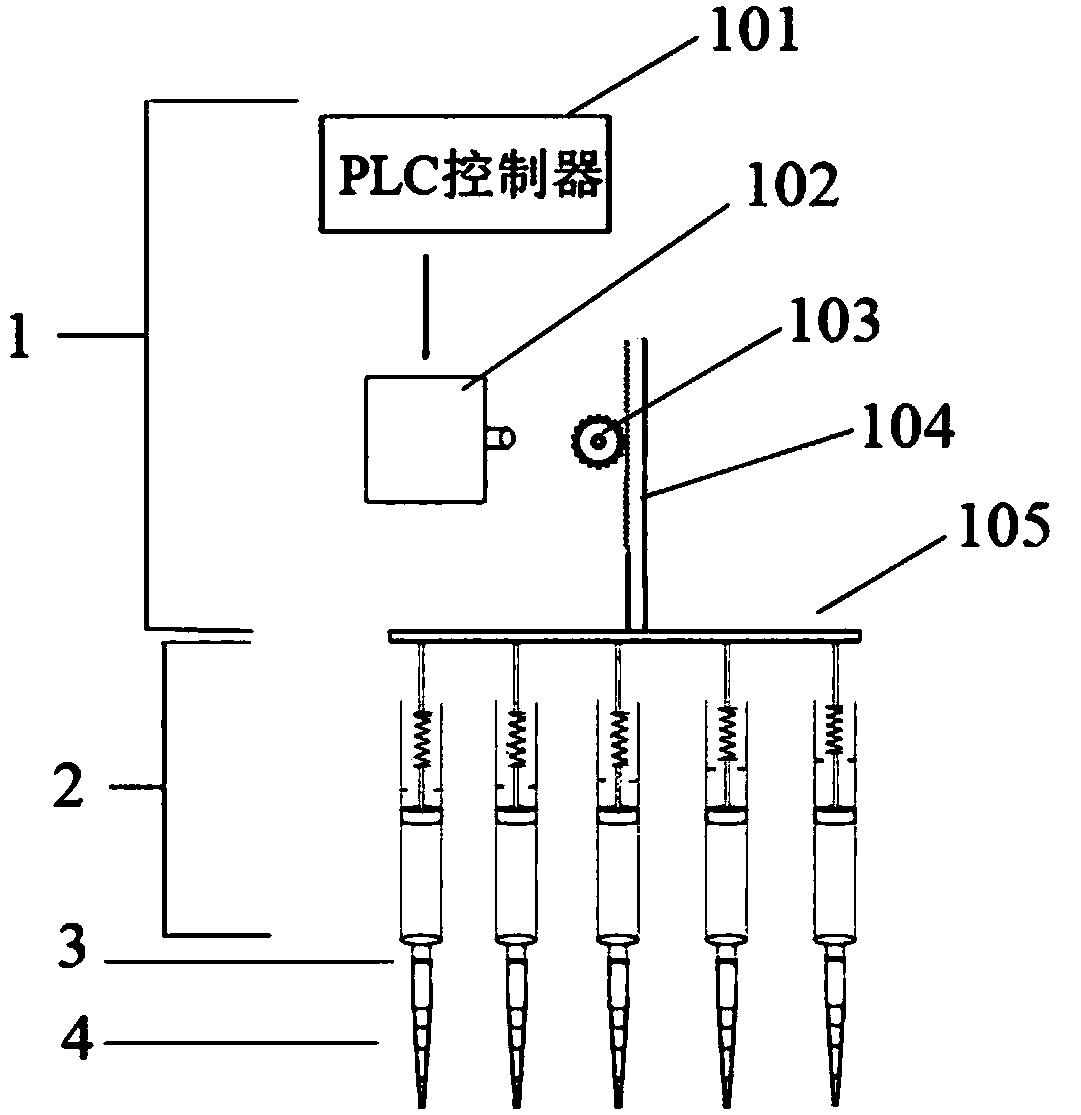

[0016] like figure 1 As shown, a 5-channel pipette includes 1 control assembly 1, 1 piston assembly 2, 5 sleeves 3, 5 suction heads 4, and the control assembly 1 includes 1 PLC controller 101, 1 step Into the motor 102, a gear set, a rack 104, and a T-shaped connecting rod 105. The gear set includes 1 driving gear and 1 driven gear 103, the T-shaped connecting rod 105 includes 1 vertical bar and 1 horizontal bar, the PLC controller 101 is connected with the stepping motor 102, and the rotor bearing of the stepping motor 102 is fixed There is a driving gear, the driving gear meshes with the driven gear 103, the driven gear 103 meshes with the rack 104, the rack 104 is installed on the upper end of the vertical rod of the T-shaped connecting rod 105, and the horizontal rod of the T-shaped connecting rod 105 and the piston assembly 2 connected to the upper end.

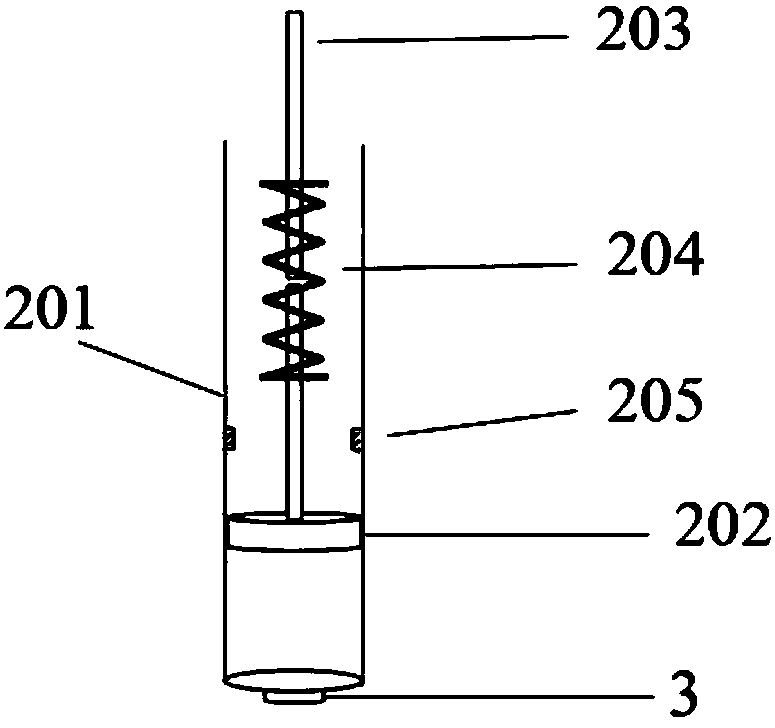

[0017] like figure 2 As shown, a piston group includes a piston barrel 201, a piston 202, a piston rod 203 and a s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Inner diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com