Nano particle composite as well as synthesis method and application thereof

A synthesis method and technology of composite materials, applied in the direction of nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of complex preparation process and lack of catalytic performance, and achieve the effect of high degree of automation and continuous sterilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1, preparation of mesoporous silica SBA-15

[0028] The basic preparation process of this embodiment is as follows:

[0029] S1. Dissolve P123 in ultrapure water, stir and add hydrochloric acid solution and mix well, then add tetraethyl orthosilicate and stir; wherein, the mass volume ratio of P123 to ultrapure water is 0.05±0.03g / ml; add hydrochloric acid Stir the solution for at least 1 hour before, the concentration of hydrochloric acid solution is 3.4±0.5mol / L, the mass volume ratio of P123 to hydrochloric acid solution is 0.06±0.03g / ml; the mass volume ratio of P123 to ethyl orthosilicate is 0.44±0.25 g / ml, add tetraethyl orthosilicate and stir for at least 12 hours.

[0030] In addition, keep the temperature at 36°C±10°C during the whole process of step S1.

[0031] S2. Move the resulting mixture to a polytetrafluoroethylene autoclave for heating and stirring, then filter and dry the resulting solid;

[0032] Wherein, the heating and stirring tempera...

Embodiment 2

[0037] Example 2, Preparation of polydopamine-modified mesoporous silica

[0038] The mesoporous silica SBA-15 obtained in Example 1 and dopamine are ultrasonically mixed in a buffer solution. The mass ratio of mesoporous silica SBA-15 to dopamine is 1:0.2-1.2, and the buffer solution has a pH of 7.0-12.0 and a concentration of 1-100mmol / L Tris-HCl buffer, the mass volume ratio of mesoporous silica SBA-15 to Tris-HCl buffer is 1.6±1mg / ml, and the ultrasonic mixing time is at least 6 hours; then centrifuge and collect the precipitate , the centrifugation rate is 8000±4000rpm, and the centrifugation time is at least 3 minutes; the precipitate is washed and dried, and the precipitate is washed with ultrapure water at least 3 times; the polydopamine-modified mesoporous silica is obtained.

[0039]Specifically, the mass of mesoporous silica SBA-15 is 50 mg, the mass of dopamine is 10-60 mg, the buffer is 30 ml of Tris-HCl buffer with pH 8.5 and 10 mmol / L, and the ultrasonic mixing ...

Embodiment 3

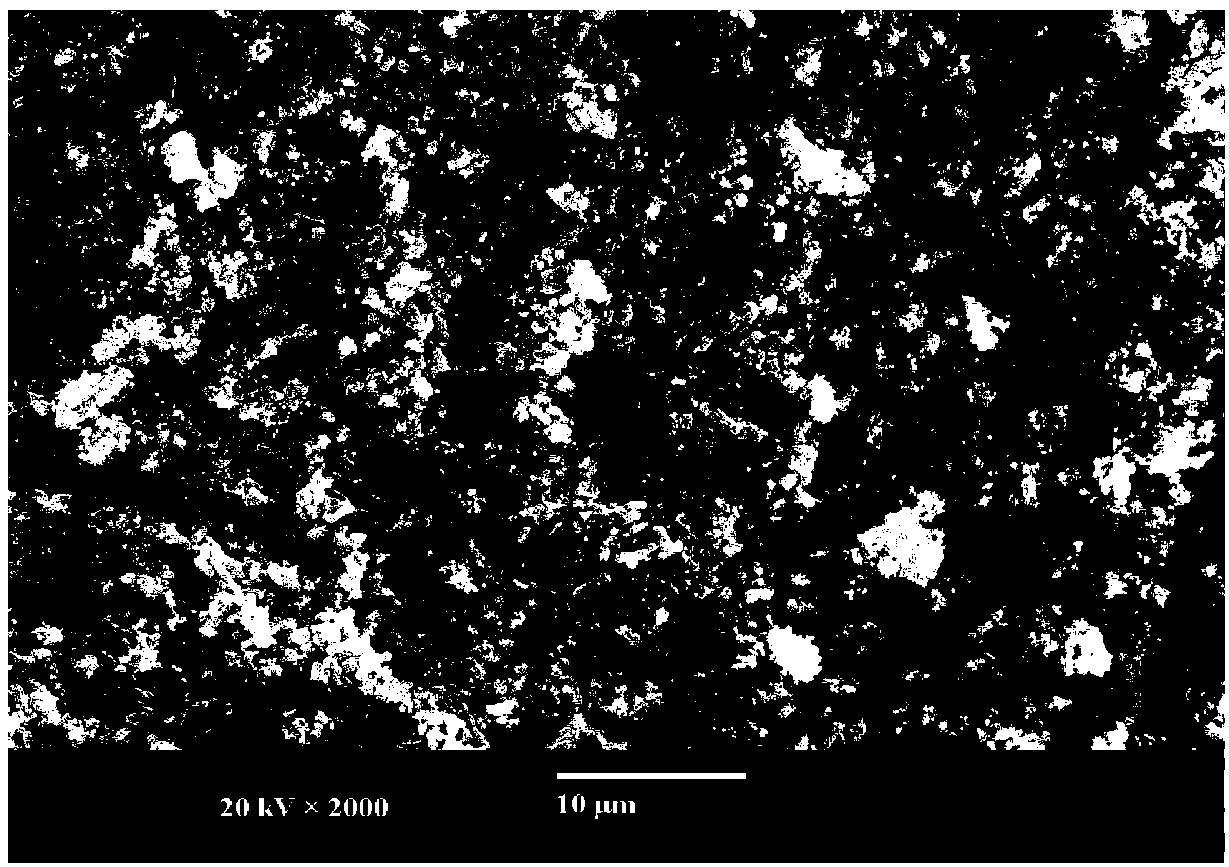

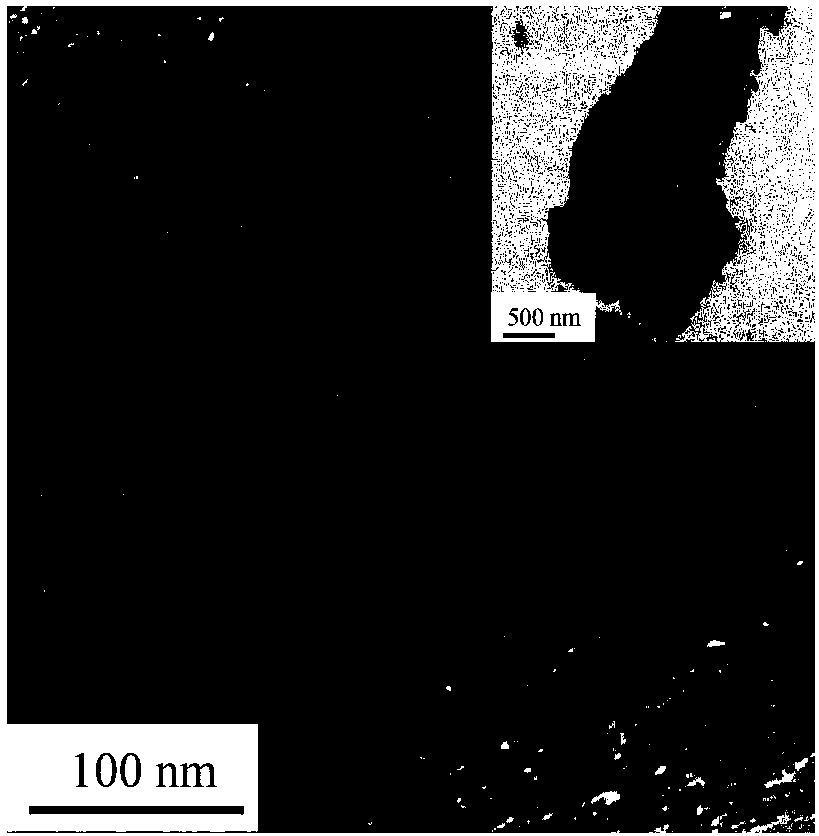

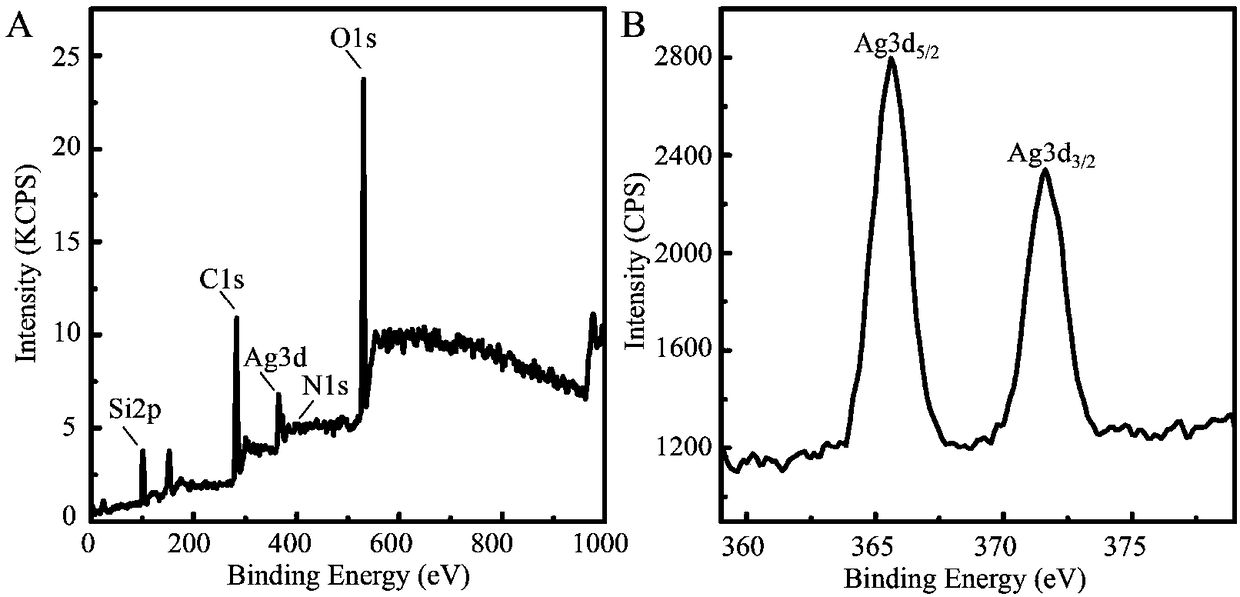

[0041] Embodiment 3, the preparation of nanoparticle composite material

[0042] Stir and mix the polydopamine-modified mesoporous silica obtained in Example 2 with the soluble silver salt solution, then centrifuge and collect the precipitate; after washing and drying the precipitate, the polydopamine-modified mesoporous silica immobilized with silver nanoparticles, namely nano Particle composite finished product.

[0043] When stirring and mixing, the temperature of the solution is 60°C-100°C, the pH of the solution is 7.0-12.0, and the stirring and mixing time is at least 6 hours. The mass volume ratio of the polydopamine-modified mesoporous silicon oxide to the soluble silver salt solution is 6.6±5mg / ml, and the silver ion concentration in the soluble silver salt solution is 32±20mmol / L. The centrifugation rate is 8000±4000rpm, and the centrifugation time is at least 3 minutes; the precipitate is washed at least 3 times with ultrapure water.

[0044] Specifically, the pol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com