Automated control system of brewing of soy sauce

A technology of automatic control and soy sauce, which is applied in the direction of food science, etc., can solve the problems of low degree of automation and high labor intensity, and achieve the effect of realizing automation, ensuring standardization, and saving manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

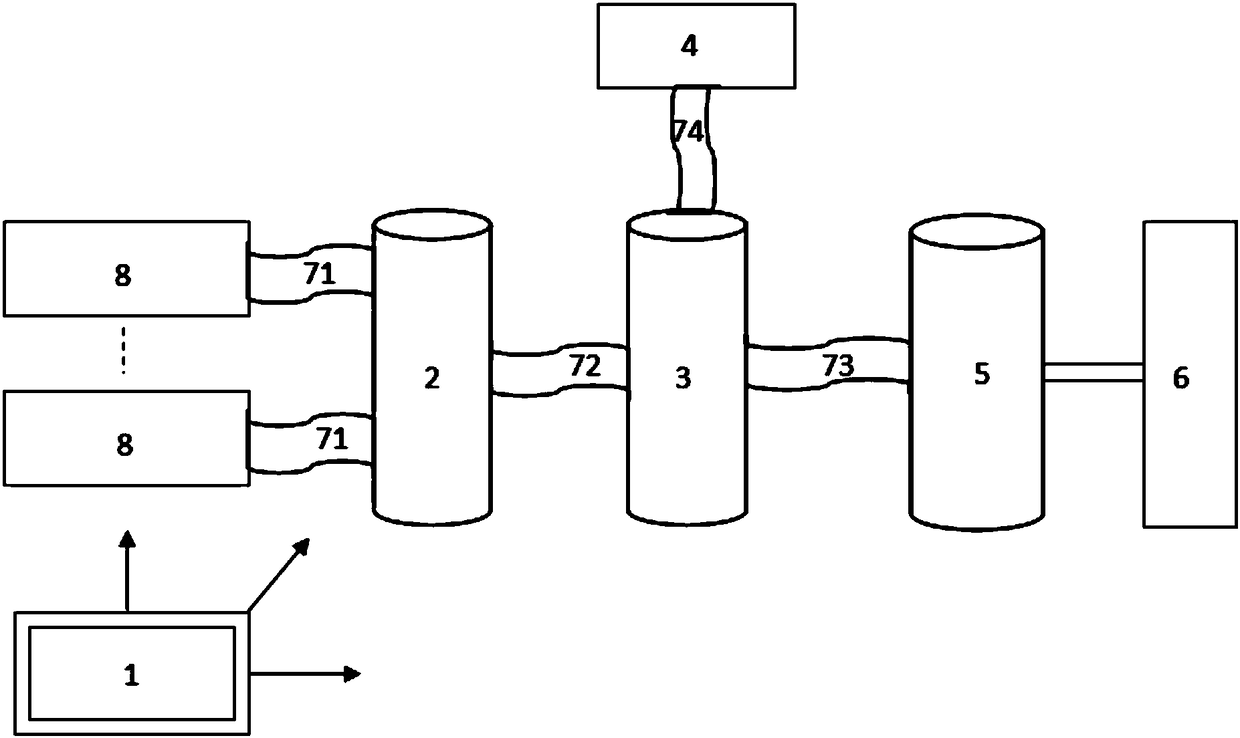

[0048] A kind of automatic control system 100 of soy sauce brewing, such as figure 1 As shown, it includes: a main controller 1, and a steamer 2 connected to the main controller 1, a koji making device 3, an advanced koji assembly 4, a fermentation device 5, an oil pouring device 6, a material transmission device 7 and at least one Raw material feed assembly 8. Wherein, the raw material feeding assembly, the steamer, the koji making device and the fermenting device are connected successively through the material conveying device and the materials are transported by the material conveying device, and the fermenting device is also connected with the oil pouring device.

[0049] This embodiment can realize the automation of soy sauce brewing. The main controller is provided with the process of soy sauce brewing. The main controller controls each link of soy sauce brewing, which ensures the standardization of soy sauce brewing, realizes the automation of soy sauce brewing, and sav...

Embodiment 2

[0051] On the basis of Example 1, as figure 2 As shown, the material conveying device 7 includes: a first material conveying device 71, a second material conveying device 72, a third material conveying device 73 and a fourth material conveying device 74 respectively connected to the main controller.

[0052] The raw material feeding assembly is connected with the steamer through the first material transmission device, and the raw materials are put into the steamer through the first material transmission device; the steamer is connected with the koji maker through the second The material transmission equipment puts the steamed material into the koji maker; the koji maker connects with the fermentation device through the third material transmission equipment, and puts the koji into the fermentation device through the third material transmission equipment; the koji feeding component passes through the fourth material transmission equipment It is connected with the koji maker, an...

Embodiment 3

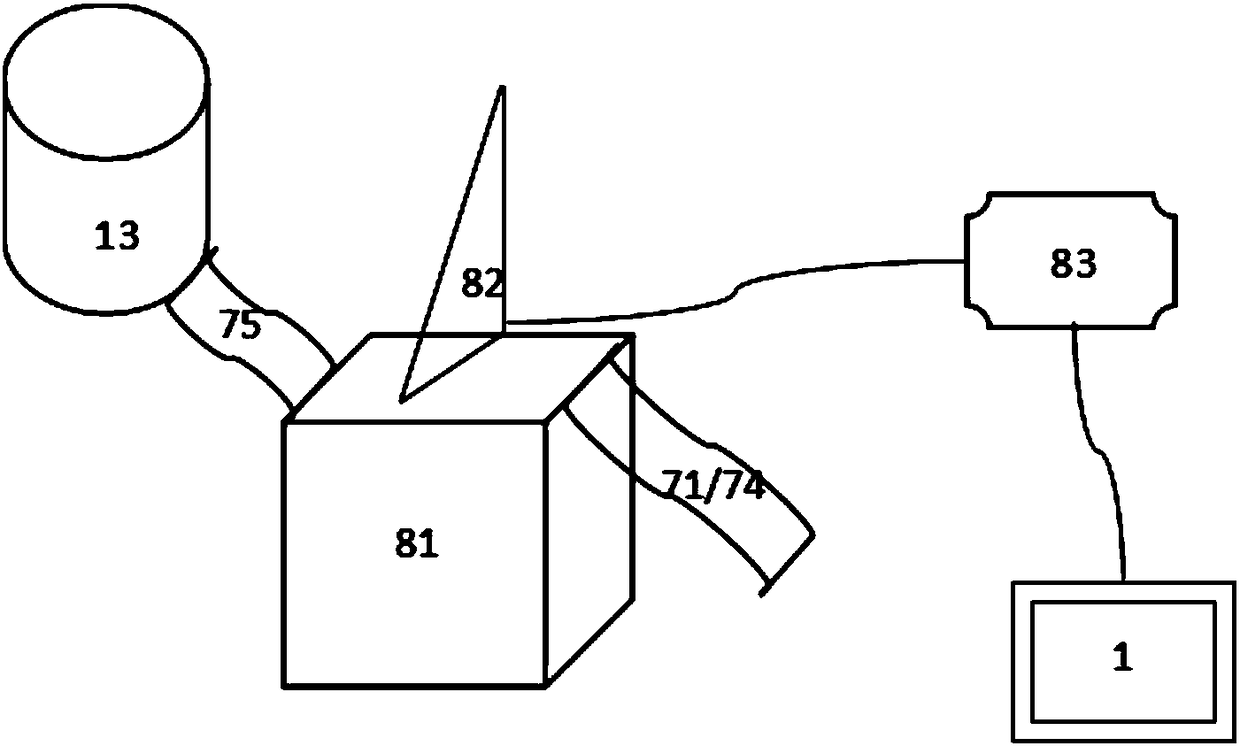

[0056] On the basis of Embodiment 1 or Embodiment 2, the material transfer device 7 also includes a fifth material transfer device 75 connected to the main controller, such as image 3 Shown, raw material feeding assembly 8 and song advancing assembly 4 all comprise: metering table 81, scraper 82, and scraper driving device 83.

[0057] The silo 13 is connected to the metering platform 81 through the fifth material transmission device 75, and the raw materials are put into the metering platform 81 through the fifth material transmission device 75; The scraper driving device is electrically connected, and the scraper driving device is also connected to the main controller. Driven by the scraper driving device, the scraper scrapes the raw materials on the metering platform to the first material conveying equipment or the fourth material conveying equipment; the metering platform Also connected to the main controller.

[0058] Because the main controller is connected with the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com