Equipment spot inspection method, device and server

A technology of server and point inspection, which is applied in the direction of collaborative operation devices, instruments, data processing applications, etc., can solve the problem that infrared temperature measurement guns cannot store test data, etc., and achieve the goal of eliminating hidden dangers in production safety, improving efficiency, and improving accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

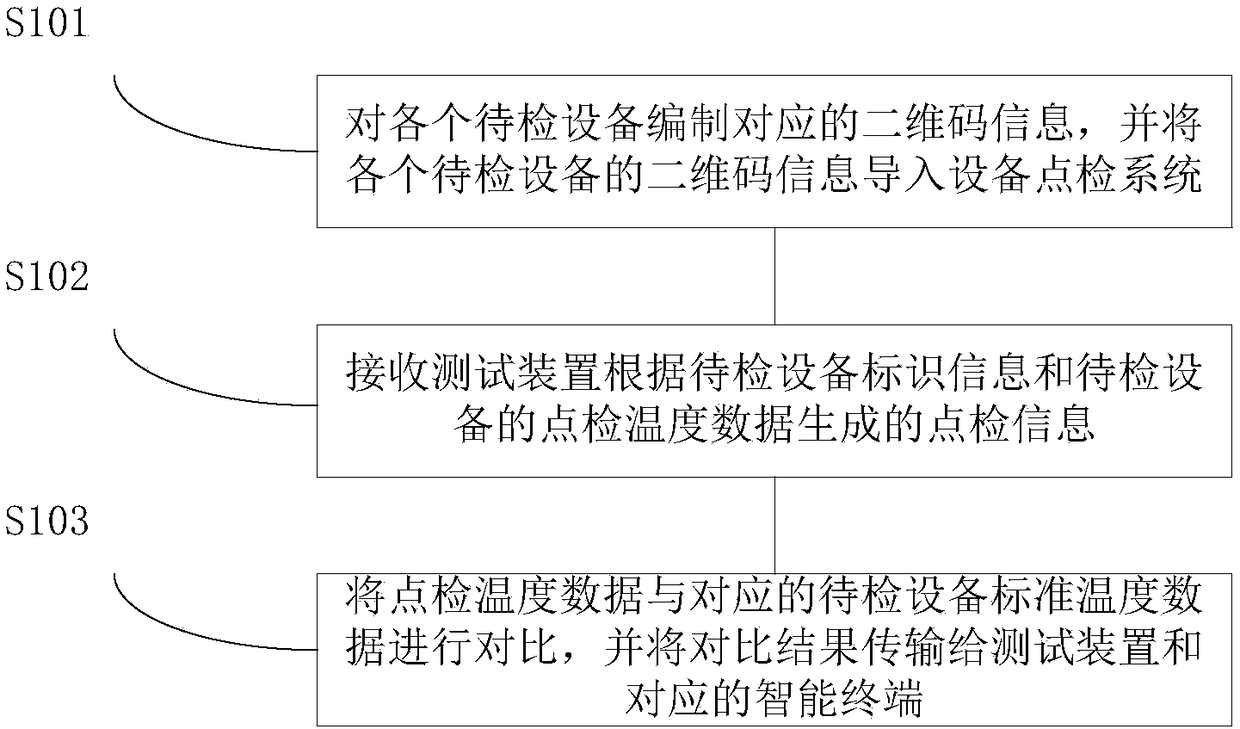

[0048] see figure 1 , a schematic flow chart of a method for equipment spot check provided by an embodiment of the present invention, which is described in detail as follows:

[0049] Step S101, compile corresponding two-dimensional code information for each device to be inspected, and import the two-dimensional code information of each device to be inspected into the device inspection system, where the two-dimensional code information includes the identification information of the device to be inspected and the temperature of the device to be inspected Standard data.

[0050] Wherein, the identification information of the device to be inspected may include the name of the device to be inspected, the name of the components of the device to be inspected, the model of the device to be inspected, the number of the device to be inspected, and the location information of the device to be inspected. The server imports the QR code information into the equipment inspection system. E...

Embodiment 2

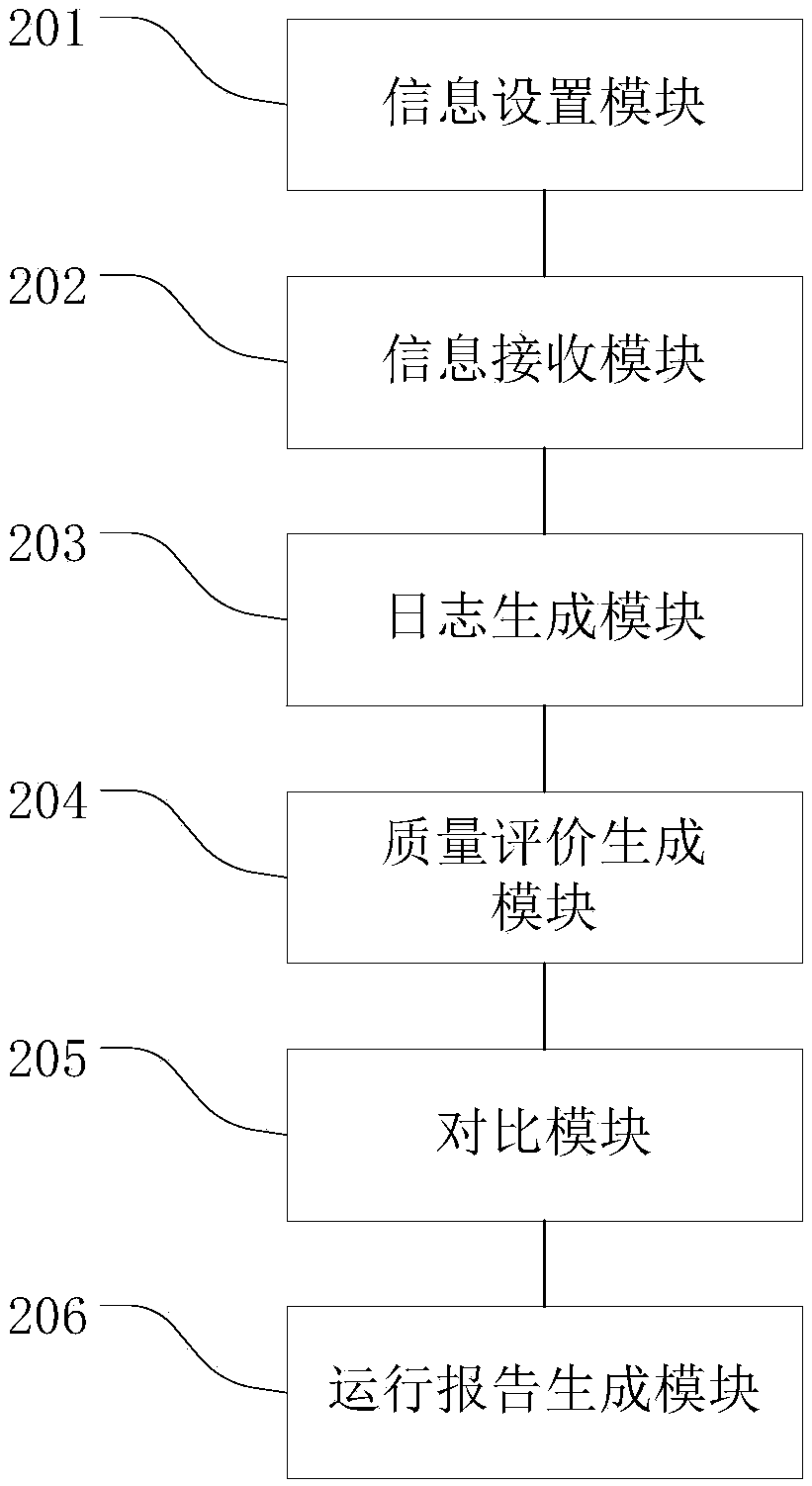

[0071] Corresponding to the equipment inspection method described in the above embodiment, figure 2 The device inspection device provided by the embodiment of the present invention is shown, which is applicable to the server side. see figure 2 , the device includes: an information setting module 201 , an information receiving module 202 and a comparison module 205 .

[0072] The information setting module 201 is used to compile corresponding two-dimensional code information for each device to be inspected, and import the two-dimensional code information of each device to be inspected into the device inspection system, where the two-dimensional code information includes identification information of the device to be inspected and The temperature standard data of the equipment to be inspected;

[0073] The information receiving module 202 is configured to receive spot inspection information of the testing device, where the spot inspection information is information generated...

Embodiment 3

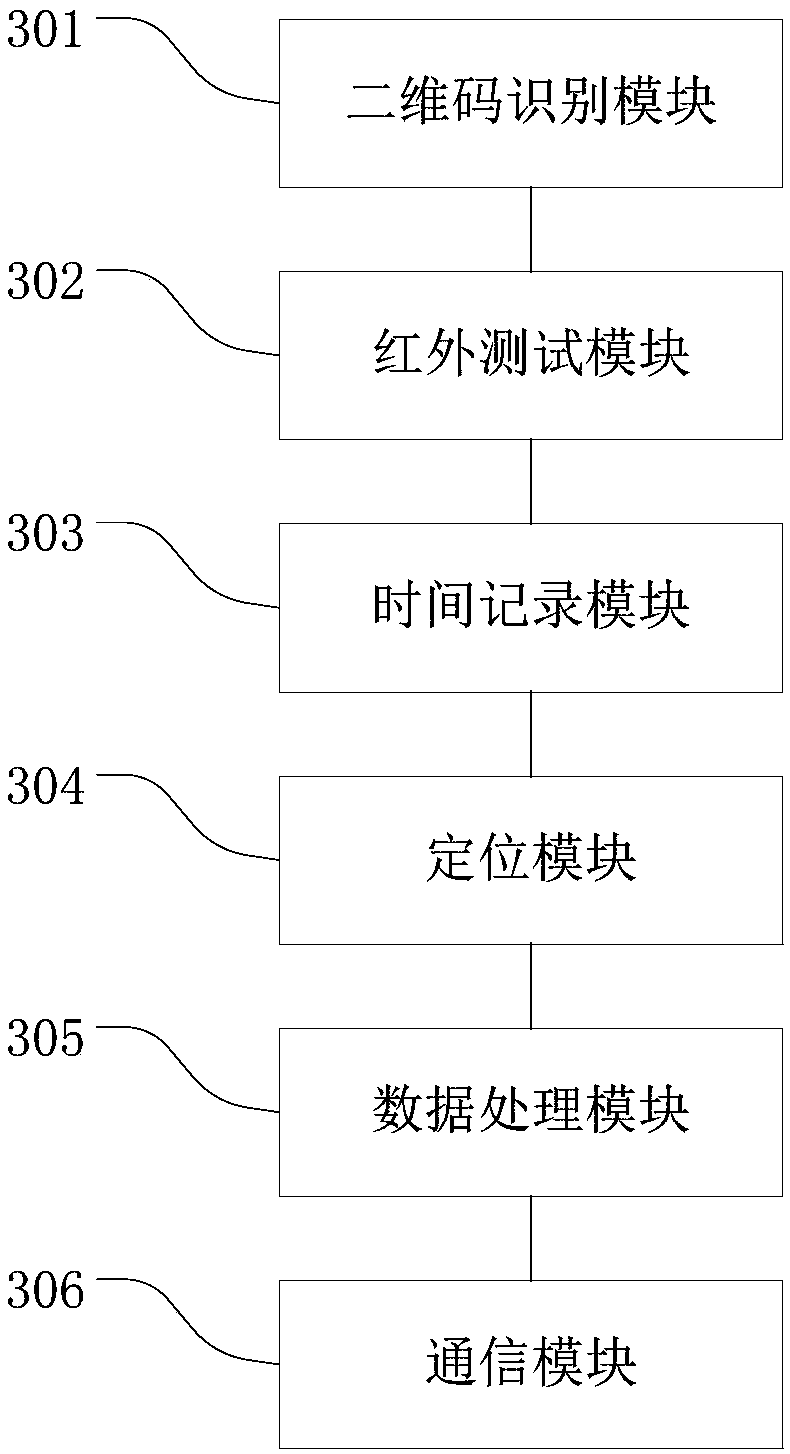

[0081] Corresponding to the equipment inspection method described in the above embodiment, image 3 The device inspection device provided by the embodiment of the present invention is shown, which is applicable to the side of the test device. see image 3 , the device includes a two-dimensional code identification module 301 , an infrared test module 302 , a time recording module 303 , a positioning module 304 , a data processing module 305 and a communication module 306 .

[0082] The two-dimensional code identification module 301 is configured to acquire two-dimensional code information of the device to be inspected, where the two-dimensional code information includes identification information of the device to be inspected, and sends the identification information of the device to be inspected to the data processing module.

[0083] The infrared test module 302 is used to measure the temperature data of the device to be tested, and obtain the spot inspection temperature da...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com