An Accurate Calculation Method for Dynamic Simulation of Tension Pay-off

A calculation method and dynamic simulation technology, applied in calculation, computer-aided design, design optimization/simulation, etc., can solve problems such as insufficient guiding significance, inaccurate calculation, and large amount of calculation in tension setting-out construction, and achieve convenient guidance on site The effect of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

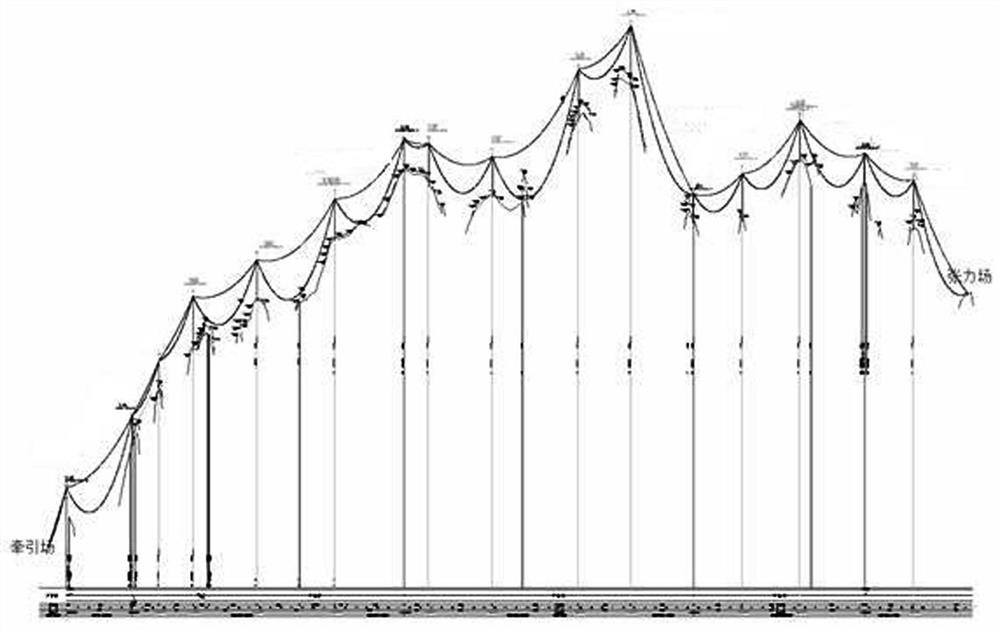

[0055] Such as figure 1 with figure 2 As shown, the present invention is an accurate calculation method for tension pay-off dynamic simulation, comprising the following steps:

[0056] A: Establish a traction force calculation model

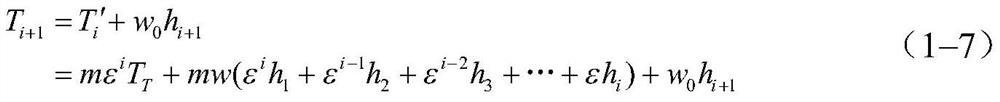

[0057] Let the self-gravity per unit length of each sub-conductor be w (N / m), and the self-gravity per unit length of the traction steel rope be w 0 (N / m), the resistance coefficient of the wire pulley to the wire is ε, and the resistance coefficient of the wire pulley to the traction steel rope is ε 0 , the axial tension of each sub-conductor at the outlet of the tension machine is T T (N), the axial tension of the traction rope at the entrance of the tractor is T P (N), the total axial tension of the thread on the tension field side of the pay-off block and the traction field side of the i-th base tower pay-off block is respectively:

[0058] T i , T i '(N);

[0059] Let the height difference of the wire suspension point of the No. 1 f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com