Large forging concentricity detecting device based on distance measuring principles and detecting method

A technology for detection devices and large forgings, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of insufficient measurement accuracy and susceptibility to environmental influences, and achieve a wide range of sizes, short measurement time, and fast measurement speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

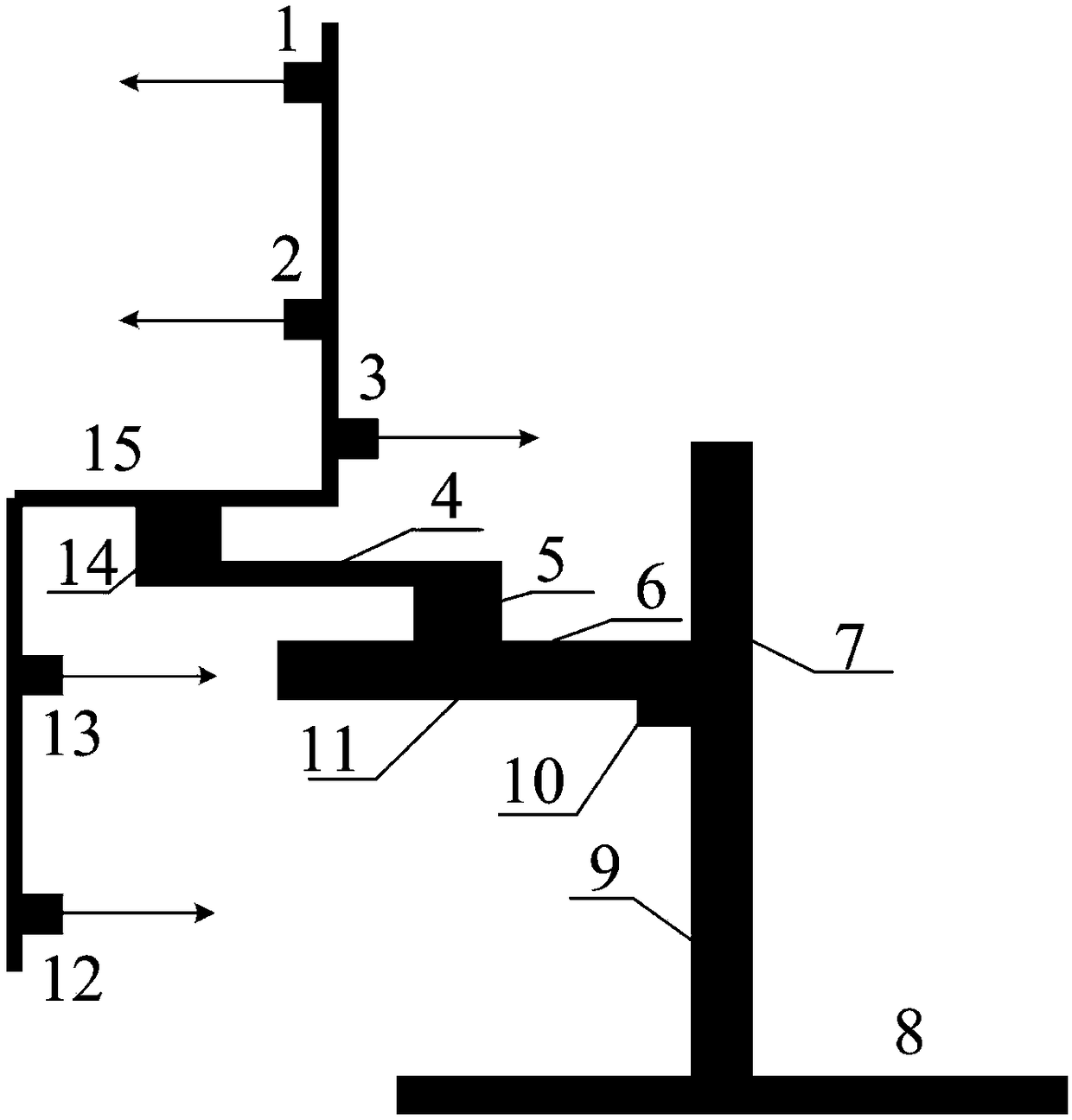

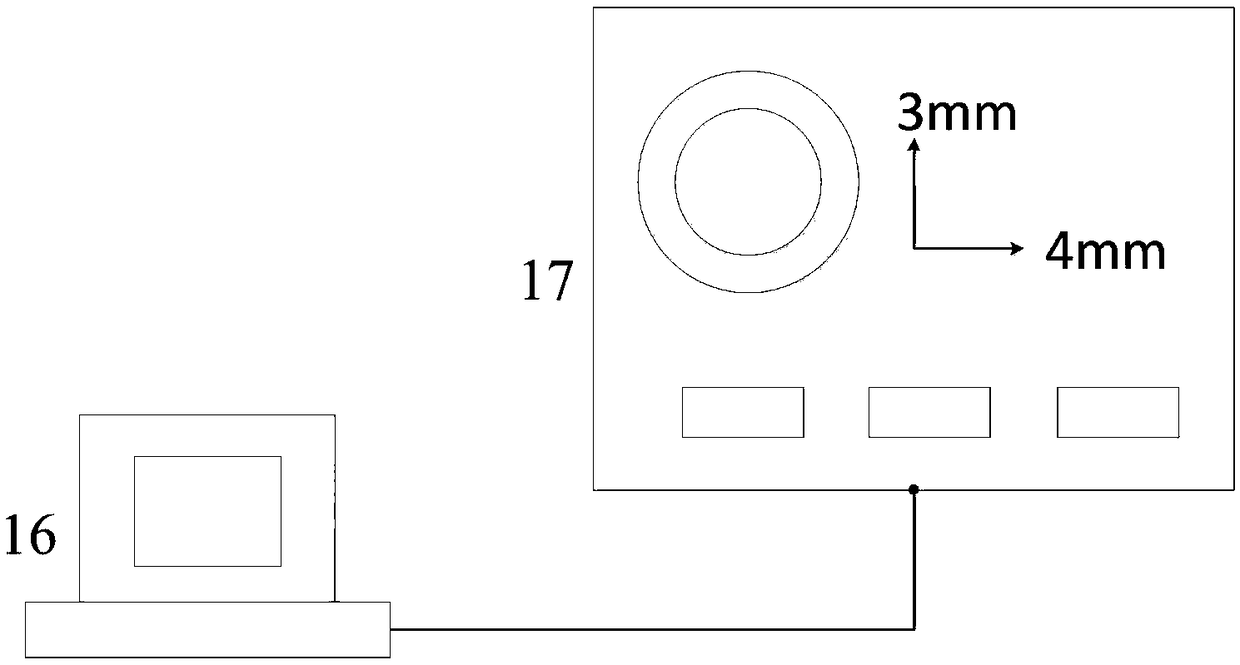

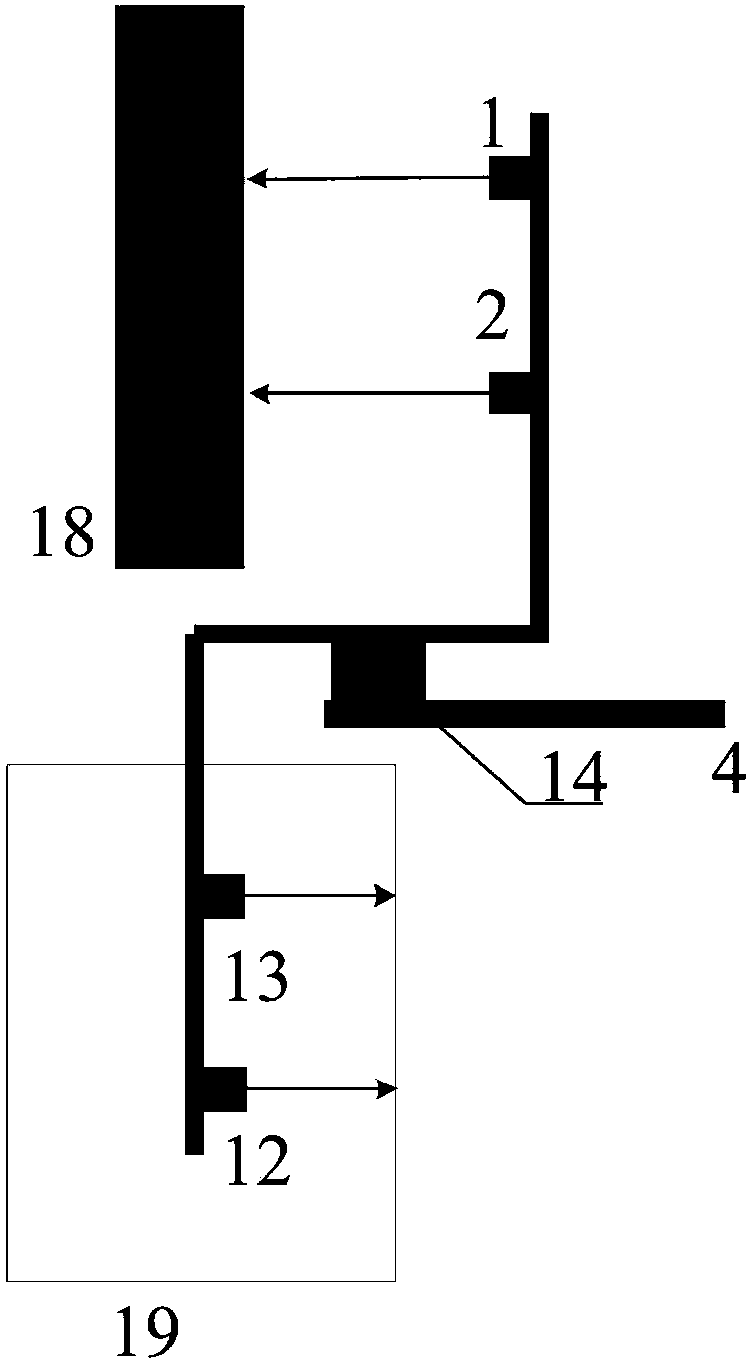

[0025] A concentricity detection device for large forgings based on the distance measuring principle of the present invention, such as figure 1 As shown, it includes a laser detection device, a detection drive device, a control processing device and a display device 16; wherein the laser detection device is mainly composed of a right-angle Z frame 15 and five laser rangefinders; the detection drive device is mainly composed of a base 8, a bracket 7 , the first horizontal frame 11, the second horizontal frame 4 and three servo motors;

[0026] Described laser detection device comprises right-angle Z word frame 15 and five laser rangefinders, and right angle Z word frame 15 comprises the first section, the second section and the third section, and the first section and the third section are equipped with electric control Telescopic rod; the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com