Constant-tension warp and k'o-ssy feeding machine

A Kesi machine, constant tension technology, used in looms, textiles, textiles and papermaking, etc., can solve the problems of excessive warp tension fluctuation, inconsistent weaving gap size, poor opening clarity, etc., to improve the speed of weft threading. , to ensure the straightness and uniformity, the effect of clear weaving mouth opening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

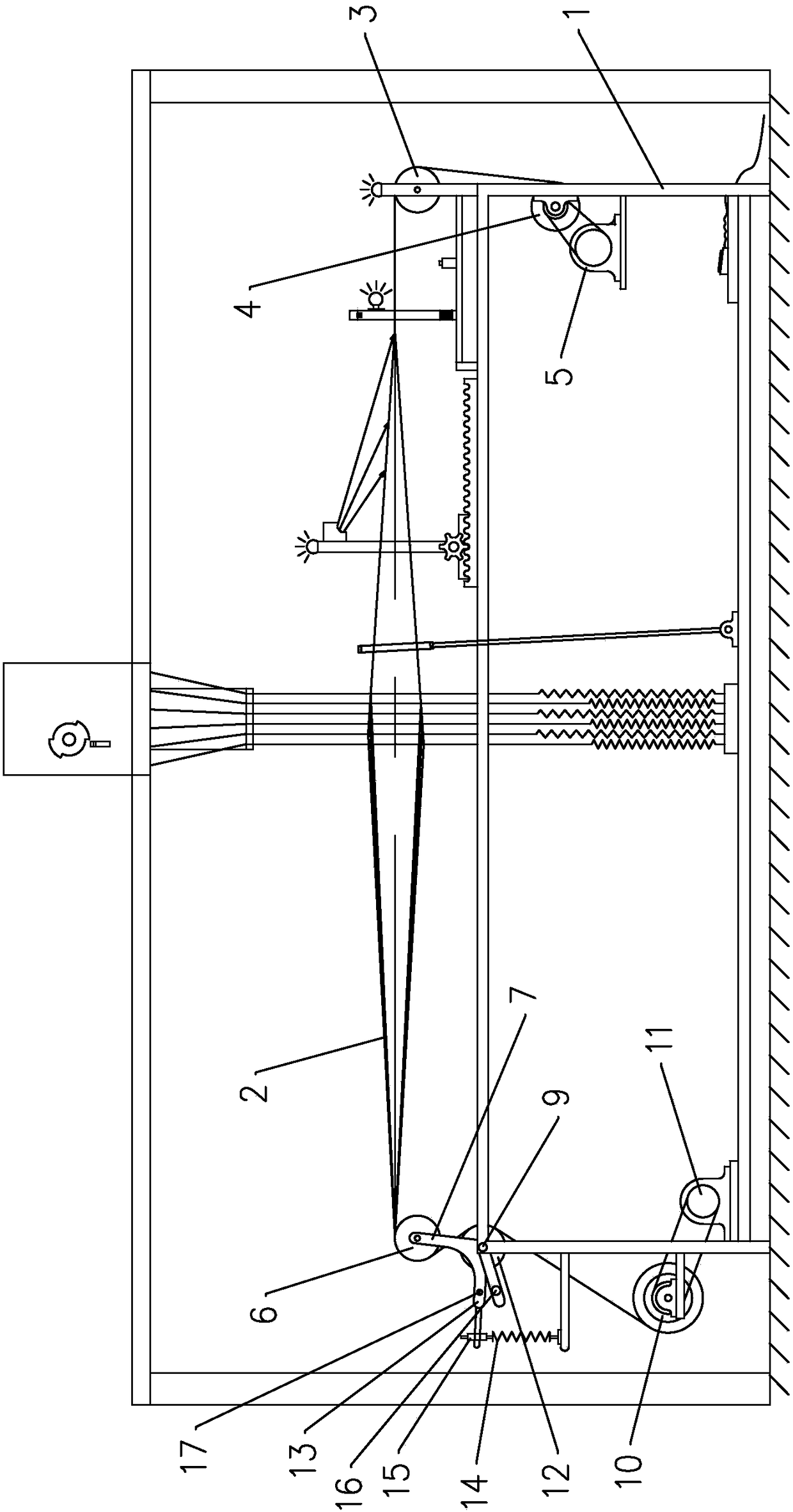

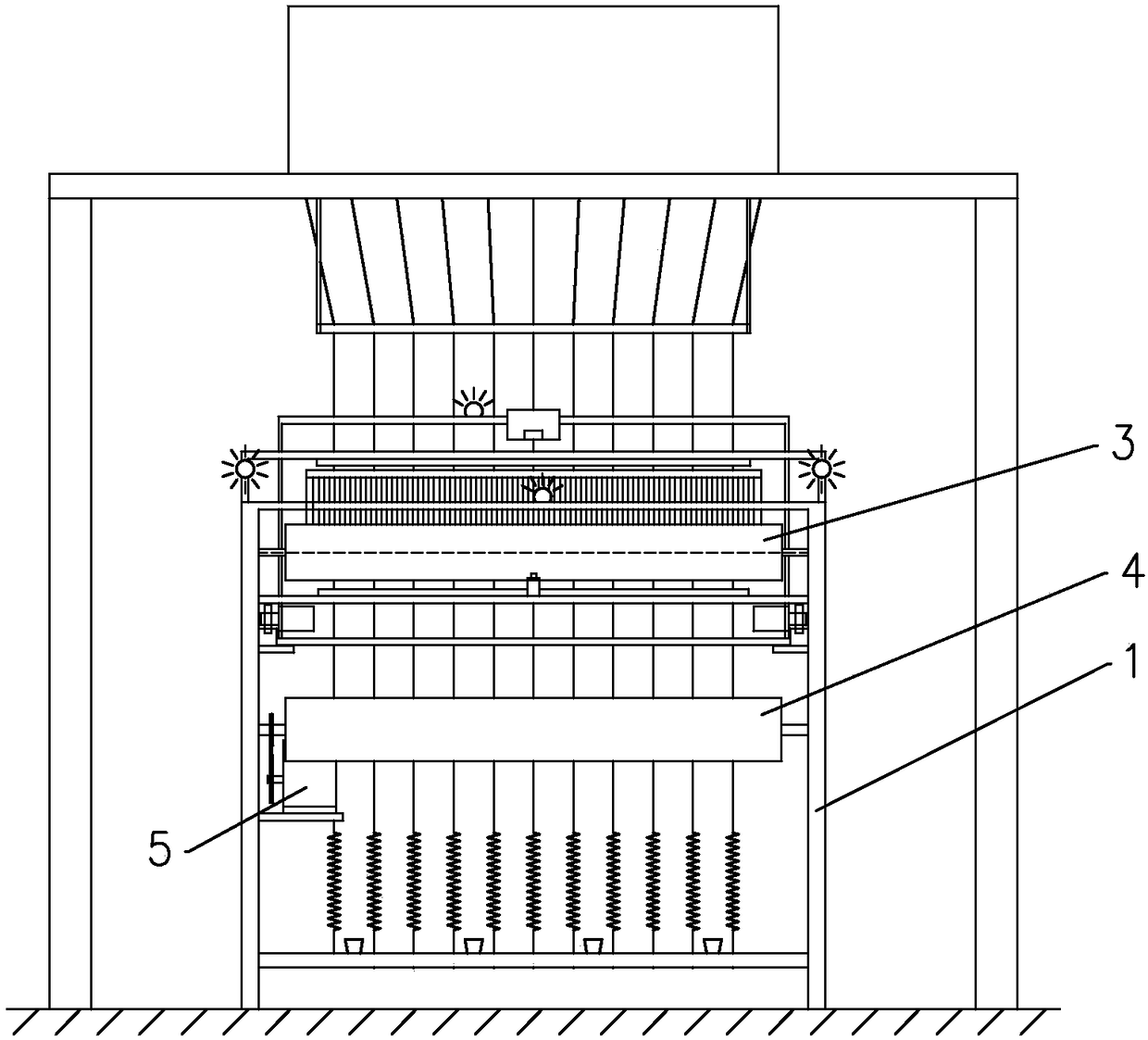

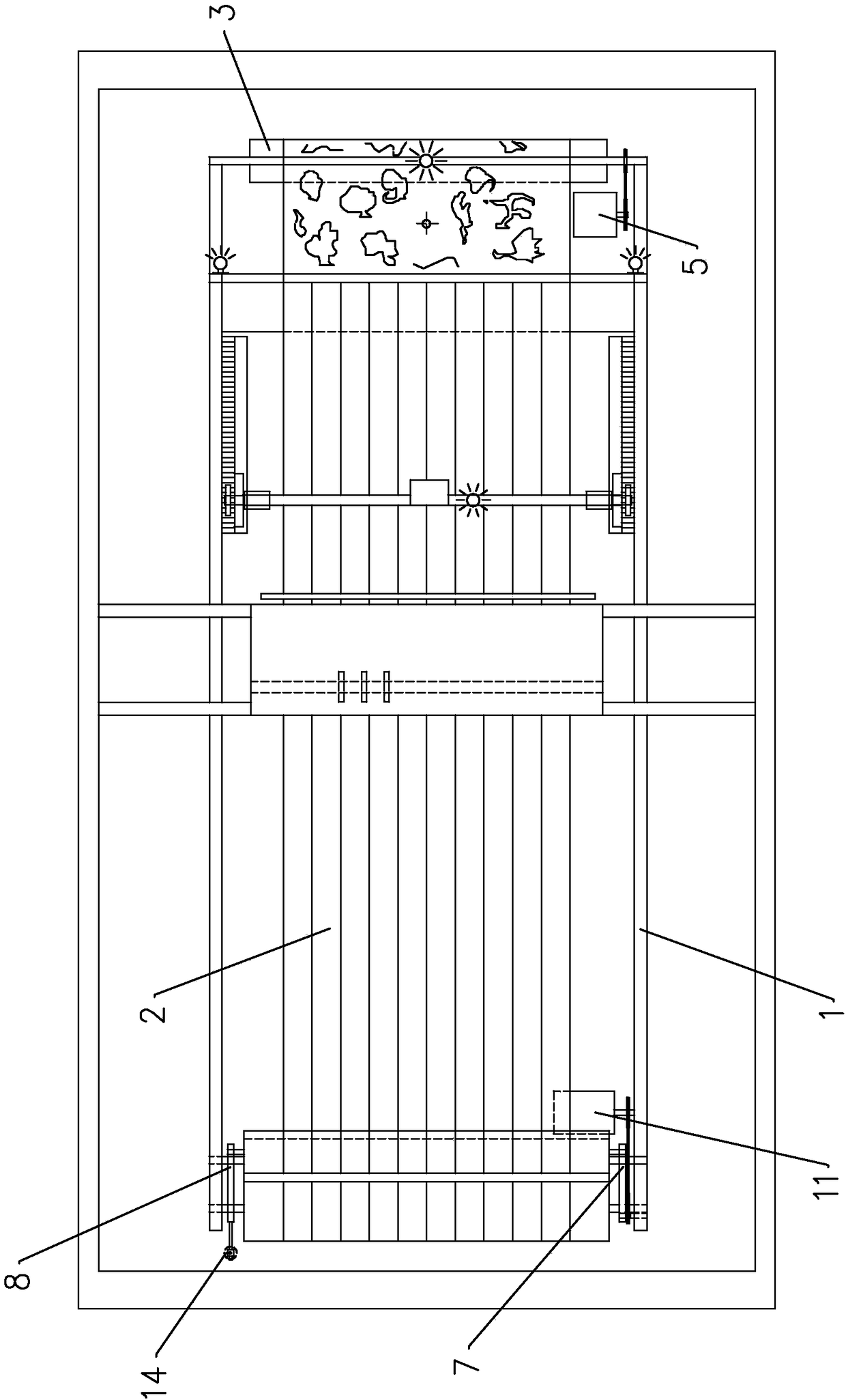

[0021] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the silk tapestry machine with constant tension force of the present invention comprises a frame 1 of the silk tapestry machine, and one end of the frame 1 of the silk tapestry machine is provided with a front chest beam 3 along the left and right direction, and the front breast beam 3 and the silk tapestry machine frame 1 The installation is connected, the bottom of the front chest beam 3 is provided with a cloth roll 4 along the left and right direction, and the left and right ends of the cloth roll 4 are rotatably installed on the Kesi machine frame 1, and one end of the cloth roll 4 is driven by the cloth roll. The power output shaft of the motor 5 is connected by transmission, the cloth rolling driving motor 5 is a servo motor, the cloth rolling roller 4 can be driven by the cloth rolling driving motor 5 to wind the finished Kesi, or the cloth rolling roller 4 can be rotated by hand. Rewinding Kesi ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com