Cobalt salt chemical conversion solution and application thereof

A technology of cobalt salt chemistry and conversion liquid, applied in the direction of metal material coating process, etc., can solve the problems of large human injury, serious environmental pollution, and high energy consumption, achieve reasonable formula, improve corrosion resistance and adhesion, and form film. Efficiency improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0018] Example 1-6:

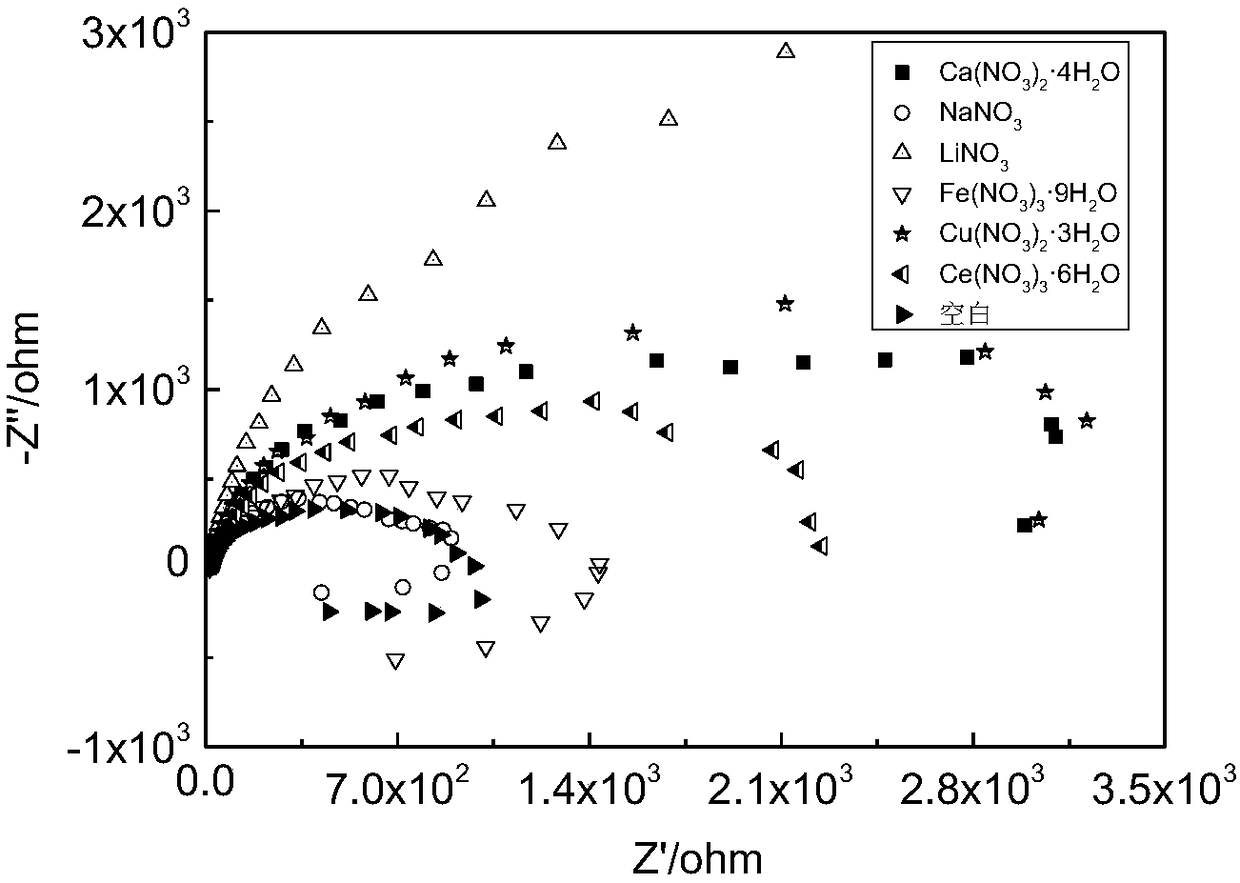

[0019] Inorganic film-forming accelerator H under different oxidant conditions 2 O 2 The influence experiment of the prepared conversion liquid.

[0020]

[0021] In order to determine the optimal components of the additives in the formula, select the same amount of 6 additives for parallel experiments, and keep the other components and dosages in the formula exactly the same. Through the following process flow, the 6 kinds of cobalt salt chemical conversion solutions are compared and analyzed:

[0022] (1) Pretreatment:

[0023] Degreasing, alkaline washing and acid washing are performed on the surface of the aluminum sheet to remove oxide film and oil stains.

[0024] (2) Chemical transformation:

[0025] A) Preparation of the conversion solution: accurately weigh the components in the above table, place them in a beaker after weighing, add 1L of water, stir to dissolve and heat in a water bath to 50°C.

[0026] B) Conversion into film: The pretreated aluminum she...

Example Embodiment

[0028] Example 7-12:

[0029] Inorganic film-forming accelerator NaClO under different oxidant conditions 3 The influence experiment of the prepared conversion liquid.

[0030]

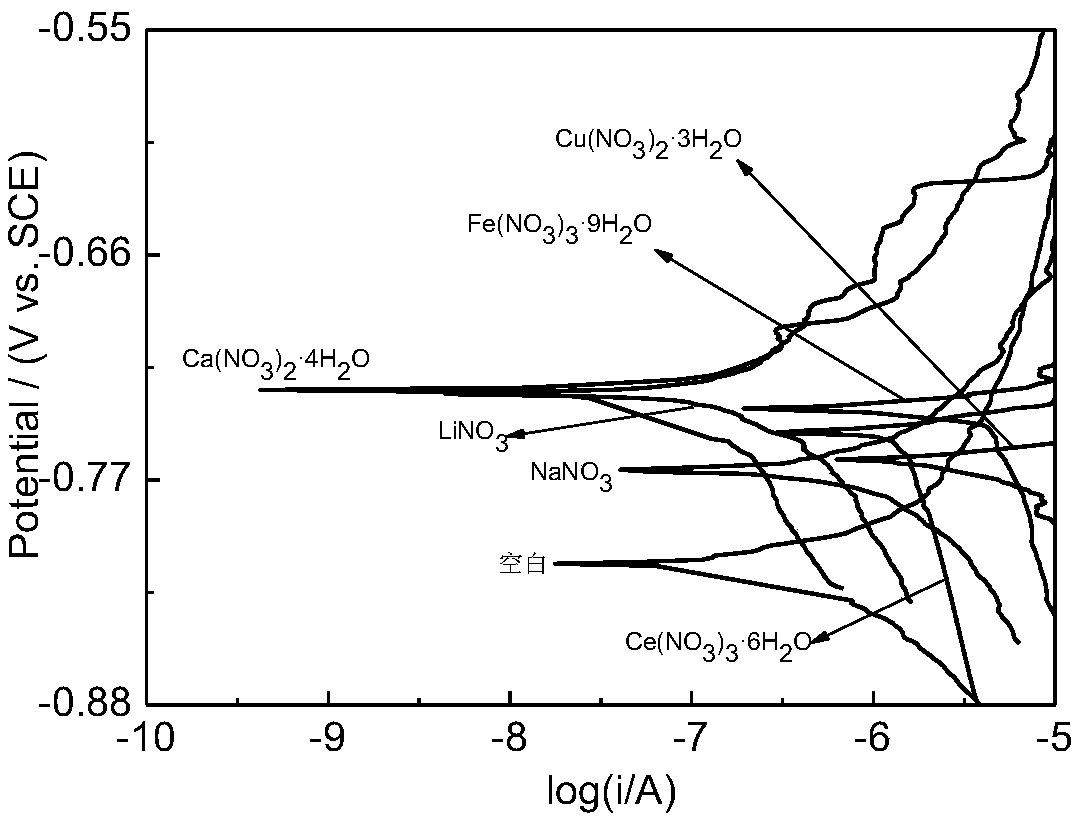

[0031] Through the process flow described in Example 1, the Tafel curve of the conversion film formed from 6 kinds of cobalt salt chemical conversion solutions in 3.5% (wt) NaCl solution was measured, and the results are as follows figure 2 Shown.

[0032] by figure 2 It can be seen that adding Cu(NO 3 ) 2 The self-corrosion current density is obviously greater than that of other nitrates. From the perspective of self-corrosion potential, the inorganic film forming promoter is NaClO 3 Cu(NO 3 ) 2 When the oxidant is used, the self-corrosion potential of the conversion solution is only higher than that of NaNO 3 The oxidant is larger, indicating that the electrochemical reaction can obtain the relatively smallest motive force for controlling the corrosion reaction, so that the corrosion rate of the aluminum ...

Example Embodiment

[0033] Examples 13-17:

[0034] Organic film-forming accelerator C under different oxidant conditions 10 H 20 O effect experiment on the preparation of the conversion liquid.

[0035]

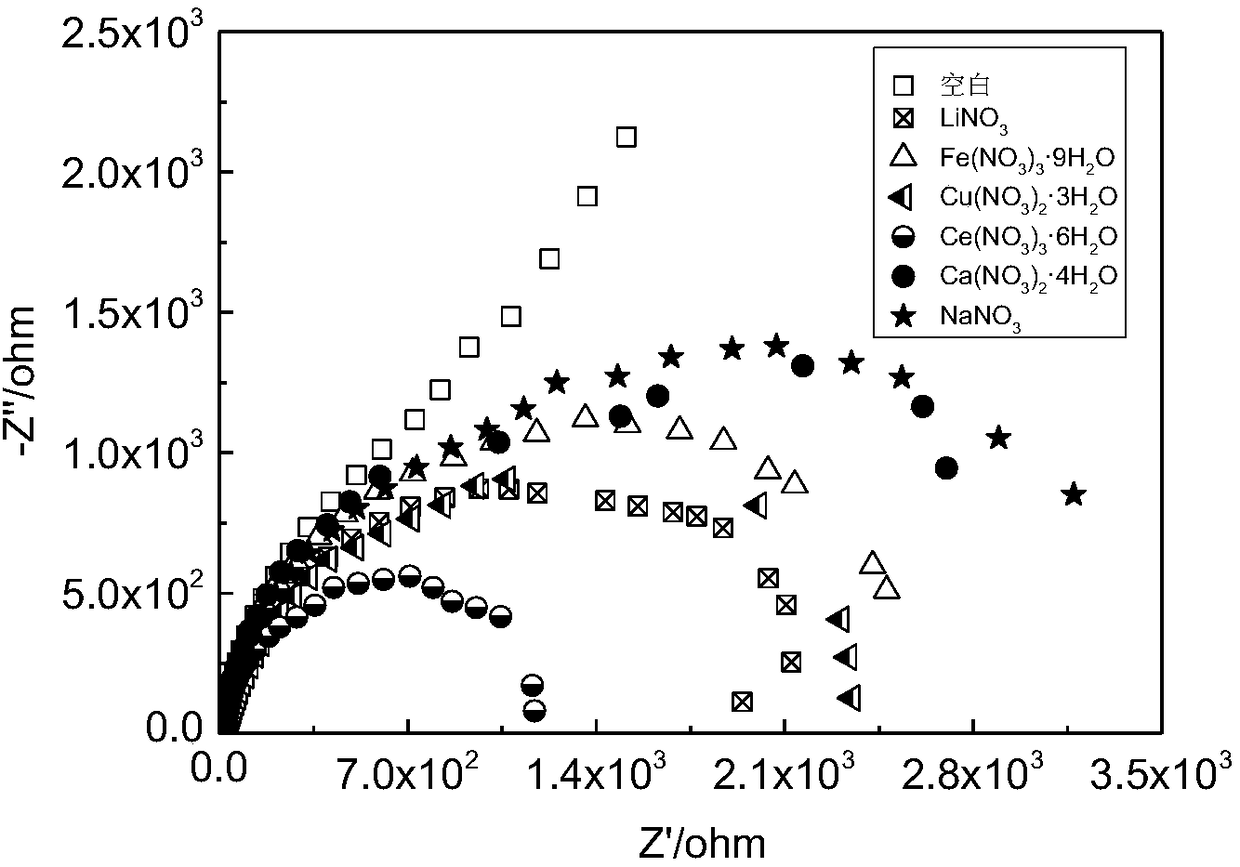

[0036] The process flow described in Example 1 was used to determine the corrosion resistance of the conversion coating formed from six cobalt salt chemical conversion solutions. The results are as follows image 3 Shown.

[0037] by image 3 It can be seen that adding Fe(NO 3 ) 3 , LiNO 3 And Ce(NO 3 ) 3 The conversion liquid has a complete semicircle in the high frequency area and Fe(NO 3 ) 3 The corresponding capacitive reactance arc radius is the largest, indicating that Fe 3+ The addition of the resulting conversion coating has strong corrosion resistance. Join NaNO 3 , Ca(NO 3 ) 2 , Cu(NO 3 ) 2 The capacitive reactance arcs of the conversion solution and the blank solution in the high-frequency region are not complete. The curve in the low-frequency region is approximately a straight line, which...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com