Ship shafting alignment technology with permanent magnet type journal-sticking shaft generator

A shaft generator and permanent magnet technology, which is applied to ship components, ship construction, ship design, etc., can solve the problems of long cycle time and huge workload, and achieve the goals of reducing shipbuilding cycle time, ensuring installation quality, and saving construction costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with embodiment, but protection scope of the present invention is not limited to this:

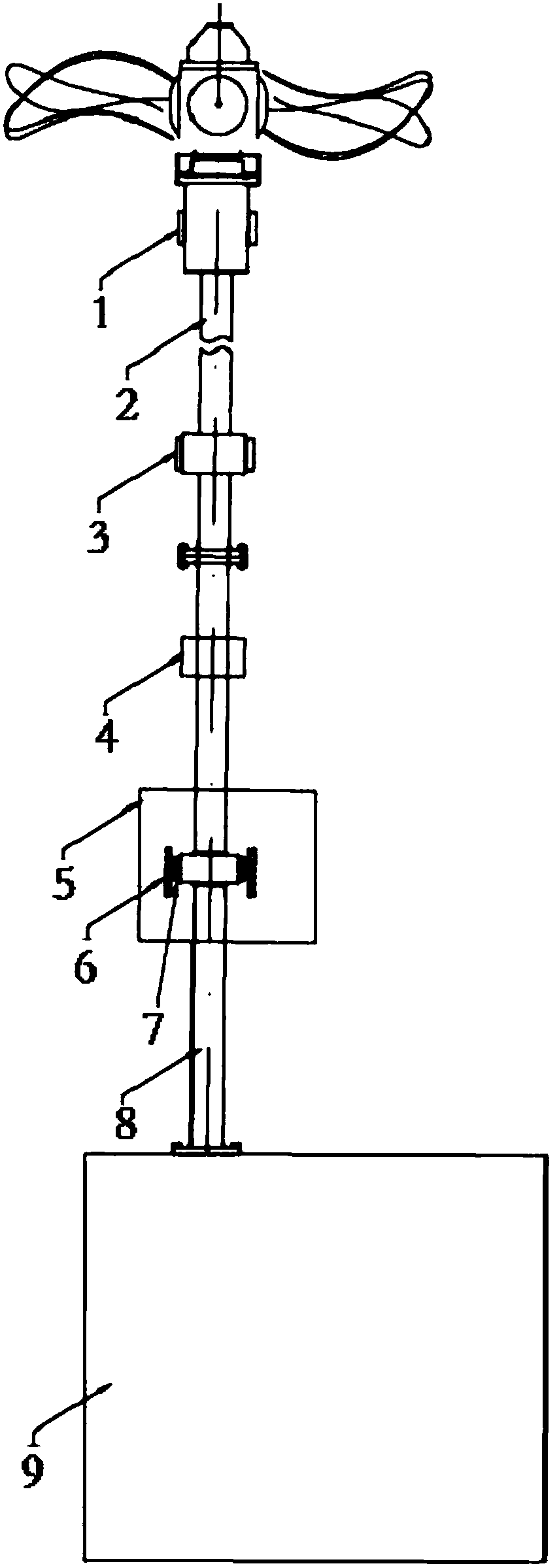

[0025] combine figure 1 Shown is a schematic diagram of a ship shafting with a permanent magnet shaft-holding shaft generator, a ship shafting alignment process with a permanent magnet shaft-holding shaft generator, which includes the following steps:

[0026] S1. Calculate the theoretical value according to the shafting alignment calculation book (the shafting alignment calculation book is matched with each ship when it leaves the factory, which belongs to the known technology): calculate the final shafting state (the final shafting state refers to the permanent The corresponding shafting bolts (specifically including: the connecting bolts between the tail shaft 2 and the rotor shaft 8, and the connecting bolts between the rotor shaft 8 and the main engine 9) on the basis of the magnet rotor 7 installation state) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com